Diary of a Restore (Thread)

Re: Diary of a Restore (Thread)

|

Foam Arrived. I got it all on. Pic below.

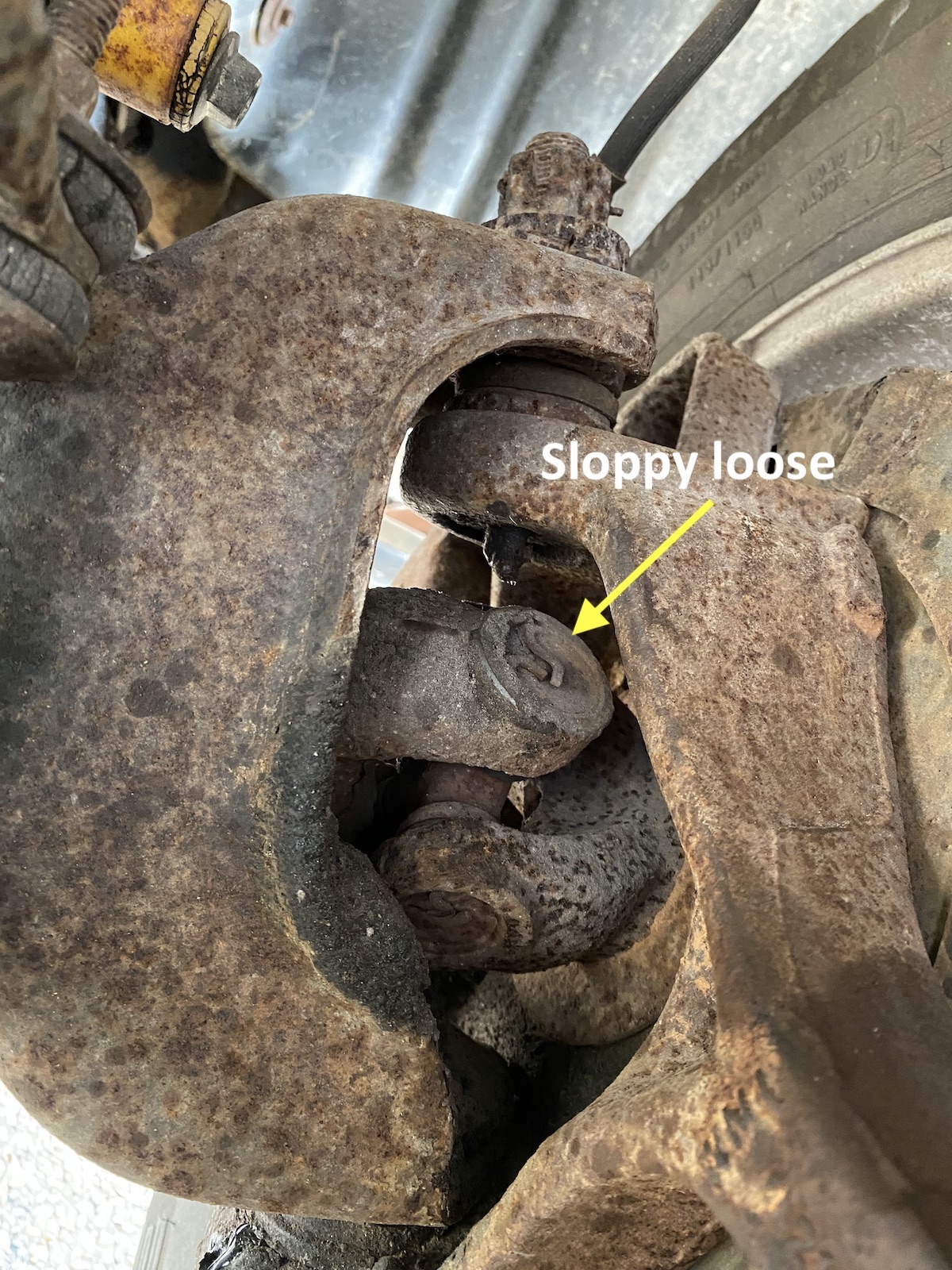

Had to take wheels off to install the trim better. And I may have discovered another issue: The D side front wheel, when I had the truck slightly jacked off the ground, I noticed the Front D-side Tie Rod end, when the wheel is moved--the bolt from the tie rod end in the Knuckle, moves back and forth like it is loose! I can see the king nut move back and forth like it is loose in the spindle, if that makes sense. So, I am hope this is just a wore out tie rod end, and NOT the tapered hole in the spindle that the bolt on the tie rod end goes through. I assume the knuckle is a tougher cast iron than that bolt. Shopping for tie rod ends now. Man, it is difficult to find 4x4 ends--MOOG (my choice usually) makes not one for D-side 4x4 and my year/fitment. Onward. Anyone ever dealt with such an issue on Tie Rod and Knuckle?

1980 Ford XLT F350

400 Engine (rebuilt to 406) Holley 2300 500 CFM manual Choke Carb Under Restore (1st time) |

|

I'm a little bugged by the description. is the castle nut tight and held by a cotter pin? if all is tight then I would pull it and inspect both male and female for wear or galling. it is a tapered connection so to wedge in place. the only wear point should be the ball joint itself. I have found them loose before most likely by having been installed with the vehicle sitting on the wheels and the wrench turner did not realize they were tightening against the geometry rather than pulling the wedge into place and basically not tightening it fully.

|

Re: Diary of a Restore (Thread)

Sorry about the description. It was hard to describe. The king nut--with the pin--was seated all the way down. The tie rod was still loose. The nut was rusted on. When I tried to get it off, the tie rod internals spun with EASE. Nut splitter? Nada. I had to wheel it apart carefully. It screwed off, and the end simply fell off. Pics below. I wonder if the correct tie rod end was even in it it was so loose and yet, it appears, the nut was bottomed out. New ends come this week. Will check fit before anything. As another thing I have to fix, the u joint on D-side tire in ONE spot is loose and can easily be moved--bearing is shot there too. So, I will be schooling myself on how to replace that as well. Last Park brake cable comes tomorrow! Amazon is taking a LONG time to deliver lately.

1980 Ford XLT F350

400 Engine (rebuilt to 406) Holley 2300 500 CFM manual Choke Carb Under Restore (1st time) |

|

please do compare the new end to the one removed; it may even help another with something to watch for. it does look as though the two were not fully seated. as for the u joint, is there any gear oil leaking out? it looks dry in the picture.

|

Re: Diary of a Restore (Thread)

Will do on all counts. The new tie rod ends are on the way. No gear oil at the u joint at all. HOWEVER, in the front differential, where the axles go in, there is some seepage. I am betting those seals are also shot.

1980 Ford XLT F350

400 Engine (rebuilt to 406) Holley 2300 500 CFM manual Choke Carb Under Restore (1st time) |

Re: Diary of a Restore (Thread)

|

OK, as Mat Requested:

I calipered the new Left Outer tie rod end, with the old. There is MAYBE a thousands of the inch difference—the new one being that much wider. The right is far thinner, by tenths. I only put the left on for now. COLD! But, it was a bear—I had to cut the adj sleeve off as it was rusted on—heat, blaster, nada. The new sleeve was a bear to screw on. I mean really tough. The left outer tie rod is left hand thread too…took me a while to figure that out. Now to the pertinent issue—the new and the old outer tie rod bottomed out with the king nut and spun—not fully seated. I am not sure this is wise, but the only way to get the nut on and torque to 50 ft. lbs., was to use 1 grade 8 washer. Then the nut pulled up the joint fully to seat and the ball joint did not spin. Is this an aftermarket issue? The one that came out and the one that went in are all similar in every way that matters. Pic follows. Rear parking brake cable is next, and I am having a lot of trouble figuring out the front D side axle shaft process. Will post in separate thread.

1980 Ford XLT F350

400 Engine (rebuilt to 406) Holley 2300 500 CFM manual Choke Carb Under Restore (1st time) |

|

Administrator

|

I've not had a problem getting them to seat, but I see no reason that a G8 washer would hurt anything. It is harder than the casting so won't flex.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Diary of a Restore (Thread)

Thanks Gary. It looks like both old and new simply ran out of threads. I will pic the washer, etc. in a later post Stay warm this weekend. We are freezing in NC.

1980 Ford XLT F350

400 Engine (rebuilt to 406) Holley 2300 500 CFM manual Choke Carb Under Restore (1st time) |

|

Administrator

|

It is currently 58F here, by far the warmest it has been for what seems like a month but is probably just a week.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

it's definitely cold here in NC. but after reading about the wind chill recorded on mt Washington yesterday I refuse to complain. its above freezing. and all the signs of spring are looming. my wife cut fresh buttercups yesterday and brought them in. can't complain about that.

as to the washer I think you are fine with it. sure, it is not supposed to be needed. in theory it's possible that the machining / casting differences are what caused this. or possibly it is from hard livin. loose taper joints wear. loose taper joints also hold moisture and rust. rusty joints wear more. and so on. if in its life it was not torqued to spec and was not seated properly this might be the result. theory for certain but if you got it torqued to spec with a washer, roll with it. in doing the safety check on an f 250 I found the drag link tightened with the castle nut and cotter pin in place yet as soon as i lifted one wheel to check for joint play it flopped like it was shot. I tightened it three more rounds to spec. there is no telling how long that truck was wandering all over the road with the driver saying "it can't be that. its new"! |

Re: Diary of a Restore (Thread)

|

Here is a pic of what I did.

The tape set the line for me to screw the new tie rod end in at the same locaiton as the old.

1980 Ford XLT F350

400 Engine (rebuilt to 406) Holley 2300 500 CFM manual Choke Carb Under Restore (1st time) |

|

Administrator

|

Yes, Mt Washington was C.O.L.D.

The washer looks just fine and can't hurt anything.  But I'd wrap that cotter pin around a bit more. I worry about getting cut on things like that when I'm under the truck. But I'd wrap that cotter pin around a bit more. I worry about getting cut on things like that when I'm under the truck.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Diary of a Restore (Thread)

Will do Gary! Warmed up a little today, and rained on me when I was looking at front axle. Called it a day as a result.

1980 Ford XLT F350

400 Engine (rebuilt to 406) Holley 2300 500 CFM manual Choke Carb Under Restore (1st time) |

|

the tape is a great idea yet none of these parts are drop in exact. that's one of the reasons they are adjustable. that should be good enough to get you to an alignment shop.

|

Re: Diary of a Restore (Thread)

|

This post was updated on .

What in the name of ZEUS?!

Tackled the parking brake sticking. Took a while to pull the drum—had to contract the brakes through the hole. At any rate got it off and saw this. What is the world did prior owners do to this? I assume here that this is a not an easy fix and requires a whole new axle as this back spindle piece is part of the entire rearend, yes? Inside there was no wet fluid, but there was a ton of gunk and and old dirt and grease—does not look like brake fluid. Brake pads look newish but they were gunked with sticky dirt and grease. Inside drum looks fine. Did not see pitting on the bearings, but did not look closely at them yet. Anyway, took a full can of CRC to get it all cleaned up. I assume there was a seal leak at some point, but not recently. Still, that spindle does not look good. Any advice from the wise men?

1980 Ford XLT F350

400 Engine (rebuilt to 406) Holley 2300 500 CFM manual Choke Carb Under Restore (1st time) |

|

it sure looks to me like a bearing or seal was removed the hard way. I think I see a track from a cutoff wheel. but all the circles are real nice. that is a mystery to me.

|

|

In reply to this post by AmericanSavage

Holy Yikes!! Someone beat the crud out of that poor spindle. Where the outer bearing rides still looks OK but where the inner bearing rides is another story. It is in pretty rough shape. The area where the seal mates is in rough shape as well. I am not sure if those are replaceable on the rear axles, but you seem to have a Dana 61 like I do. Maybe a Sterling swap is in order if they are as bad as they look in the photo.

Carl

1980 F-350 4X4; 400 C6; Dana 61 rear, Dana 50 TTB front 1984 F-250 4X4; 6.9L T19; Dana 70 rear, Dana 44 TTB front |

Re: Diary of a Restore (Thread)

|

This post was updated on .

In reply to this post by mat in tn

That cutoff part (if we are looking at the same spot) is the inner Bearing spot. The point before that (the bigger section) is where the seal rides. All those circles is dead space in the drum, then the outer bearing section. My question is, should I use Defcon to smooth it out? Sand it, etc? I would use Belzona, but, FAR too expensive. A decent repair would be like one offered for my timing chain cover--they come with sleeves for the crank so the seal seals. At least, that would work for that part of the rear spindle. The bearing part would need Defcon and precision sanding. I should add: A Speed Sleeve MIGHT work for the seal area. Just have to measure and see if they have one that fits in diameter and width. But, that inner bearing area... I am a bit stumped as to what to do.

1980 Ford XLT F350

400 Engine (rebuilt to 406) Holley 2300 500 CFM manual Choke Carb Under Restore (1st time) |

|

Administrator

|

This post was updated on .

Just use a 'Scot seal' XL design seal (no need for that SKF brand) https://vehicleaftermarket.skf.com/us/en/product-assortment/heavy-duty/wheel-end/scotseals-heavy-duty-trucks This is a seal that rides inside a seal. You drive the outer into the hub and then you glue the inner "race" of the seal onto the axle housing when you install the hub and axle. This is what I use on my 10.25" because nothing else works. Again, you can get this type of seal from a bunch of manufacturers, but just like Kleenex or Aspirin everyone knows them as Scotseal.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: Diary of a Restore (Thread)

|

Just want to thank everyone for chiming in. Much appreciated.

I am going to buy those seals, but also sleeve this side where the seal rides. What the D side looks like--tune in next week! Then onto the front axle.

1980 Ford XLT F350

400 Engine (rebuilt to 406) Holley 2300 500 CFM manual Choke Carb Under Restore (1st time) |

| Edit this page |