Hydroboost Planning

|

Administrator

|

This gonna be a looooong post.

Bill - Bingo! The distance from the brace to the block is 1 3/16", which is probably the thickness of that corner of the manifold.  Now to hydroboost specifically. I measured three different brake pedals today and will record the measurements here. These measurements are from the center of the pivot tube to the center of the stud to which the booster attaches, and are done to a 1/16" of an inch as I don't think more precision is required for this: Big Blue's F250 pedal" 3 1/2"Some other pedal: 4 1/4"Hydroboost pedal from a '95 Superduty: 2 3/4"And now to a little "detail" I didn't expect - 9C962, which is the ADAPTOR (SPEED CONTROL VACUUM VALVE ACTUATOR). It resides on the brake pedal and hits the speed control vacuum dump valve such that when the brake pedal is up the valve is closed. But any movement of the pedal opens the valve and dumps the vacuum to the speed control to disengage it. Here are what the three different ones I have look like, with the black one in the middle the original one from Big Blue:  Peeking out from under the ruler is the tab on each of those that slips over the stud on the pedal, with the adapter sitting astride the pedal and hitting the valve, like this: (Note the Nylon washer is on the wrong side of the tab.)  You may have seen this coming, but what happens when you move the stud up the pedal 3/4"? Yep, it misses.   Well, perhaps you can move the valve? Like cut the bracket down? Nope, look at the pic above. That valve can't move nearly enough to hit the adapater w/o hitting the pedal bracket first. So I made an "adapter" - that is somewhat overkill:  And here's what it looks like installed:  Last, the pedals are D.O.N.E! New cruise switch and a working clutch switch installed, as well as a pad "borrowed" from another pedal. The Nylon bushing are in great shape and everything is lubed. All I have to do now is to install it - after adding the firewall brace first.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

I was going to say you didn't have any firewall reinforcement under that red tape highlighting the Hydroboost lines.

Glad I didn't.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

I can't easily get into the cab because I can't get the doors open very far due to the lift's uprights. I can't get the truck far enough back to get them open much farther, and I doubt I can get it far enough forward to get them past the legs.

So unless I can do that, and I'll try soon, I'll have to wait until the temps come up enough outside so I can open the door enough to stick the bed out under it. Until that I'll work on other things, and there are plenty of them.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Doesn't BB have a sliding rear window???

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

LOL! Yes, he does. But that would be very, very painful. There's no seat, and given the tool box it would be a problem getting in - and out. And as soon as I got in I'd find I needed another tool.  I can get in via the doors now, but it isn't easy. And what I'd really like to do is to stand on the floor with the truck up a bit so I'm looking up under the dash. But I can't easily get in that position right now with the door only opening a maybe 12", which doesn't let me get between the lift's arms. Tomorrow we are headed out to visit a cousin that's very ill, but I may get to try to get the firewall brace in on Saturday. We shall see.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Gary, figure it as manifold + the 9/16" hex and washer face on one of the short double ended studs (I can measure on my engine if you need it).

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

Bill - I have the original manifolds so can check if I want. But since I'm using headers that's a moot point.

Which brings up a question. On that as well as at least two other spots I'll need to use a standard bolt instead of the 12-point fasteners that L&L sends. Are stainless fasteners the way to go?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Stainless, as long as it is 304 or 316 condition B, or some B16 all thread, that is a high temperature non-CRES alloy, and use a CRES nut and washer. That is what I used on my 390's right manifold where the air filter preheater attached. That will also give you the ability to space the bracket as needed, or remove the pump without taking the front bolt out of the header.

Now we need a PN for that so anyone else (like me) who does a Saginaw pump conversion can try to find one.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

In reply to this post by Gary Lewis

X2 on stainless.

My manifold bolts still look good from the '90's! Not some rusty, indistinguishable nub that you can't get a wrench on.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

In reply to this post by 85lebaront2

Bill - I'm not sure I understand what you said. The "non-CRES" bit of "or some B16 all thread, that is a high temperature non-CRES alloy" confused me. I think you are saying to use stainless but if I can't find a stainless all-thread to use a high-temp alloy and a stainless nut and washer. Is that right? Similarly, you said "304 or 316 condition B". Are you saying 304 is good or 316 condition B? I ask because I didn't understand Condition B and I found this at Diversified Metals and it says Condition B is a variant of 304.  Jim - Are you saying I should ditch the whole set of L&L 12-points and go stainless the whole way? Did you use special bolts? 304? 316? Condition B?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

I think they were 316, and they were passivated (or pickled)

Keep in mind that carriage bolts are threaded all the way. You don't need to find allthread.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

Ok guys, school me on stainless. On the Fastenal site I get to this page which has one 3/8-16 selection, and it is 18-8.

I found several results via a Google search, but the one at Bosun seems most helpful. And it has this statement: For severe environments. Of course, there are many industrial processes that require a higher level of resistance to corrosion than Type 304 can offer. For these applications, Type 316 is the answer. Type 316 is also austenitic, non-magnetic, and thermally nonhardenable stainless steel like Type 304.Is that accurate? I need 316 and not 18-8? Am I missing it at Fastenal?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

18-8 is 304, 18% chromium, 8% nickel, 316 has molybdenum as an added measurable percentage. As it says, it has a higher level of corrosion resistance than 304. Biggest issue with 304 in heating and cooling environments is chloride stress corrosion, salt from roads + water will get in and essentially etch part of the alloy until the bolt will crack, usually at the head to shank location.

The reason I used B7 all thread was availability, I could easily grab a short piece of scrap at work and unlike the harder bolt materials, Gr5 or Gr8, it is not as brittle and it's strength lies between the 2. It is a high temperature rated material, so will not soften as easily. On headers, it may not matter as much, but I was using it on factory cast iron manifolds on my 390. As far as I know it was probably originally used for joints in the Navy 1200 lb steam systems.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Administrator

|

Thanks, Bill. But are you saying that 304 (18-8) would work on headers? Or do I need to find 316? And passivated 316 at that? By the way, shouldn't I move this discussion to the Big Blue's Transformation thread?

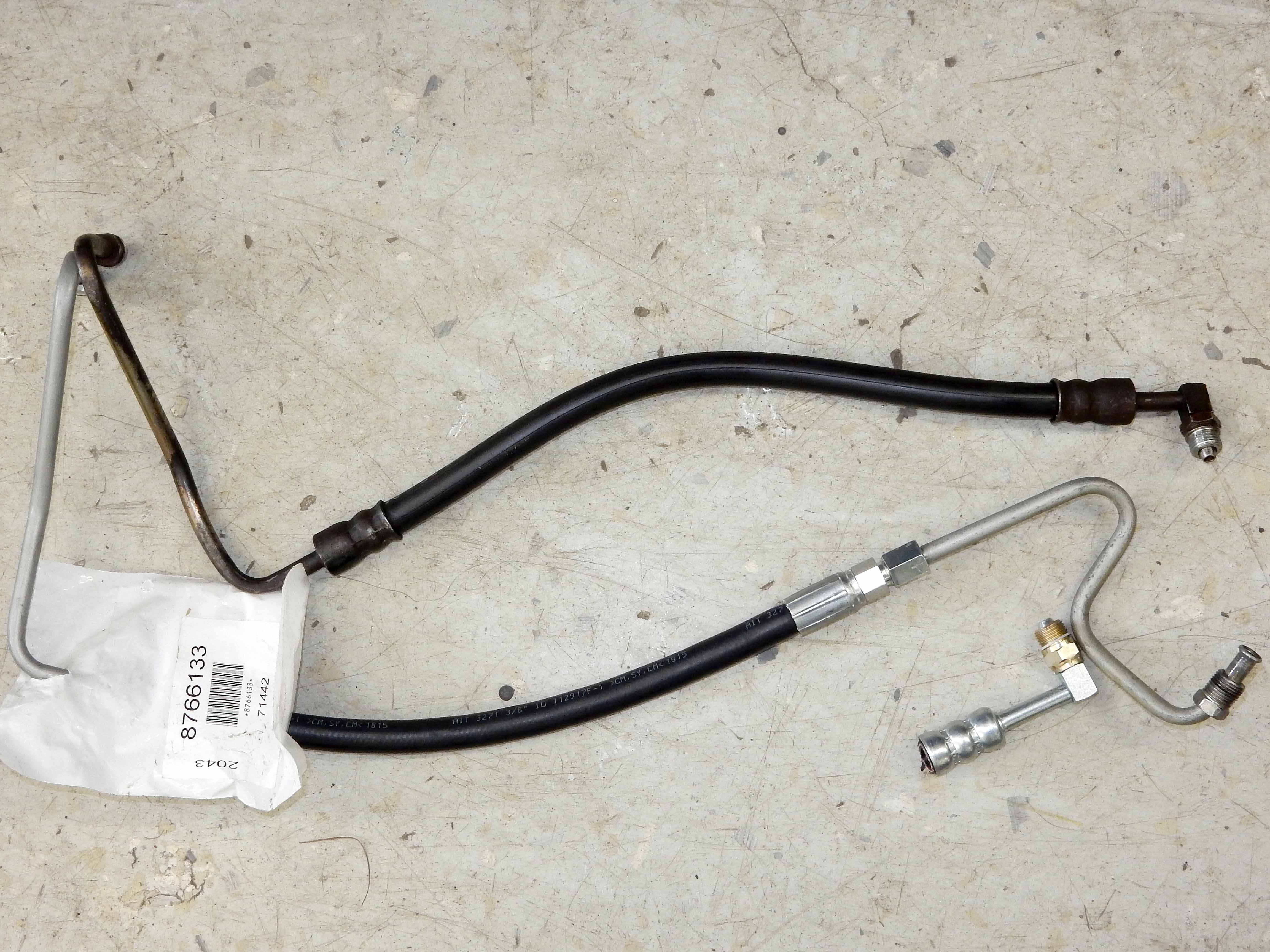

And, back to hydroboost, the new Superduty Sag pump/hydroboost line came in today. In the morn I'll put it in place and mark the top side of the hose/fitting and ensure I have good pics of the arrangement. Then we are headed to town and I'll visit Ameriflex and, hopefully, get a fitting crimped on.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Be SURE to use plenty of your favorite silver slime if you put stainless on (in?) stainless!

If not, you might not even get it tight before it becomes one.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

I'll be sure to use plenty of my favorite uckumpucky.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

This post was updated on .

The good news is that I have a hose that fits from the Sag output fitting to the hydroboost's input fitting. The less-than-good news is that it fits the Sag that was intended for Dad's truck.

So, I'm going to ask a couple of questions up front and then get into a long dialog about how this transpired. First, the Sag that works is the one Kyle/First Today got for me from a '77 - 79 Lincoln Town Car w/a 400. It is completely rebuilt and ready to go. The other Sag is the one Jonathan got me from an E350. It was working, so isn't rebuilt and probably doesn't need it. Q1: Is there any reason why one Saginaw pump is better than the other? Q2: If not and I use the Lincoln Sag then is there a reason to add the brace fitting in back? And now for the background. I went to Ameriflex, but as I got there Brandon/Bruno2 said "Kims International is a better option. Nathan down there is pretty good with hoses. That is where I get all of mine made." Well, I was at Ameriflex and Janey was waiting on me, so I went on in. Turns out the van Sag uses a "14MM bump tube" fitting and all they could do for me was to sell me a fitting that converted that to JIC #6 and then use a hose fitting. But my hose wasn't going to be long enough, and anyway that would have had the hose running right at the back of the pump, placing it near the exhaust, instead of over near the fender liner as far as it can get from the exhaust. However, they could put the flared fitting that I showed in previous posts onto my hose and it would fit the Lincoln Sag. So we went that way, and it fits nicely. The flared fitting they grafted on is on the left, and on the right you can see the new hose with it grafted on, and you can also see the old hose and the fitting that was cut off the new hose.   Here's an overall view of how it all goes together using the Lincoln Sag. If there is nothing in the way as it all goes together I'll massage the bend out of the hose from the Sag to the booster, which is the one on the left at the firewall, and keep it closer to the other two hoses.  And here is a shot from above showing the routing at the back of the pump, inc where the tee will go in the return:  And now for shots of the two pumps - and I think you can tell which has been rebuilt and powder coated. But, a few things to point out. First, the mounting bolts are different, with the Lincoln pump having 3/8-16 bolts and the SD pump having 10 x 1.5MM bolts. Second, the return tubes are at different points and angles, and the one on the Lincoln pump has a better angle and location to use the SD return line. Last, the Lincoln pump doesn't have the brace stud, but has a bolt there, so it is possible that I could put the stud on there. But I'd bet it is metric and would need to be SAE.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Gary, I'm pretty certain the 450 had a C2 pump.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

Absolutely!  Jonathan got me that Sag out of an E-Series van. I've changed the post to reflect that, I hope. My bad. Thanks!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Gary, remember the previous discussion concerning outlet fittings and flow control valves in Saginaw pumps, also the "ham can" can be swapped to build what you need. Just keep track of what you use.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

| Edit this page |