The replacing of a c6 with t19. More than just the swap

Re: The replacing of a c6 with t19. More than just the swap

|

Administrator

|

I seriously doubt you could override the electric motor with the hand crank, so it would need some kind of clutched mechanism.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: The replacing of a c6 with t19. More than just the swap

|

Administrator

|

That was my thinking too, Jim. I think the motor has a worm gear drive which can't be overcome.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Get one of them motors that turn a crank window into electric that fit the crank spline.

You might be able to use the wiring to work the motor and if it gave out remove it and use the handle. Because it would be in the out side you would need to make a cover to keep weather off it. Didn't Jeep have the wiper motor outside in the early years? Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

Re: The replacing of a c6 with t19. More than just the swap

|

Administrator

|

In reply to this post by Gary Lewis

That's the reason worm and wheel is used over bevel gears in tuning string instruments like pianos and guitars.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

I think the older jeep wagoneers had a window handle externally you stuck the key into to operate the window. That is ideally the type handle I would like. It would be made to withstand being outside full time as that is the way it is designed, but I do not have one of those just laying around.

It would be neat if you could make it a system where it could be operated both ways, but it seems like it is more likely to have an issue with an additional mechanism in place to disengage the power motor.

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

Re: The replacing of a c6 with t19. More than just the swap

|

In reply to this post by ArdWrknTrk

That's a great "outside of the box" solution there. A write up of the modification with pictures would be a great help for others having the same or similar problem as you was.

1981 F 150 Custom 300 ci with a fully rebuilt 1968 240 head Carter YFA T-18 3.25 9" rear 2WD

dual gas tanks 1990 Lincoln Town Car 5.0 AOD Home town Mc Kenzie, TN |

|

I will definitly try to make a writeup on the how to. I am not sure I have a second operator mechanism available, I will have to look at the door off the wrecked parts truck I have. Perhaps I can redo the modification of adding the operator to the power regulator i just removed. I "think" it might clear the tailgate sheet metal without cutting the hole even. So i could use it for power with the manual operator in place on a tailgate without the hole in the future. The hardest part is locating the hole for the handle to go through. Both of the tailgates I have are in less than pristine condition and are not precise on locating the regulator left and right. Both times the hole ended up a little off when trying to center on the tailgate. I resigned myself to just drilling it oversized and if i decise to leave the handle in I would use a big stainless fender washer as a "bezel". Cover the excess hole. It just occured to me that perhaps I can loosen the bolts on the regulator now and center the regulator on the centered hole... Interesting.

Something else to add on to the growing to do list. I am kind of shocked no one else actually did it.

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

|

Does anyone know if ford made a flip up emblem for a trunk lid like the old Cadillac cars had for the key? If they did I guess a person could center the emblem over the hole and then flip,it up and slide the handle in. Just would end up with the emblem centered in the tailgate at about the same height as it was originally just not on the left side.

Now it has me wondering if you could modify the latch assembly to lock on the tailgate by using door parts. So if the manual window handle was installed all the time, you could use the key to actually lock and unlock the tailgate. It would be easy to bend up some operating rods for the key to latch to make it lock and unlock. Even if someone where to roll the window down it would be unlikely they could lift a heavy toolbox up and over the tailgate that way... Perhaps I need to stop trying to come up with new ideas to work on and focus on the current list.

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

|

Turns out the the adding a manual operator is a bit more complicated, but I think I know how to fix the issue. Just need more free time.

Currently the window rolls down, except the last 2 inches of glass. It is an issue with the drivers side gear on the regulator not being long enough for the oprerator to go the full travel of the glass down. So it looks like a little more custom work will be needed, but can handle the 2 inces of glass out since i can roll it up and keep the weather out for now. The end of the window gear is probably just a handful of teeth too short. I could either splice a section of gear to that, or make a radial cut accross the gear and reindex the arm to a new location, or possibly remove the arm and flip the gear and index it into the proper position. I think flipping it would give the additional travel to the right area where the operator gear is located. A new problem for a different day. The motor has enough range to lower the window way below fully down it looks like so perhaps the best option would be a radial cut across the gear and reindex the arm and weld it in place. That way the power motor could be used in the future yet.

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

|

More progress while the forums were down...

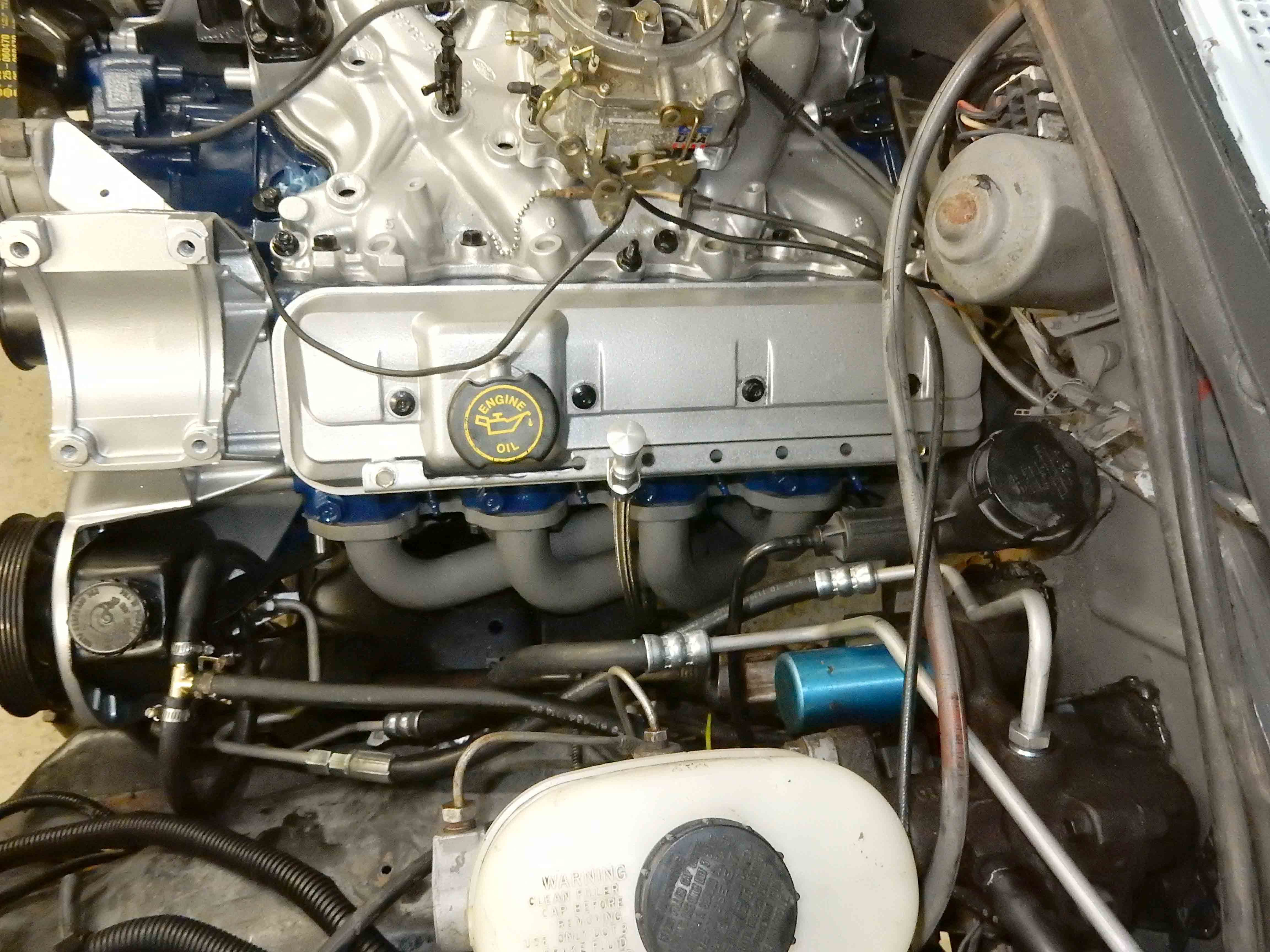

The interior portion on the conversion is buttoned up, except the shifter hole. I am planning to use the t19 tunnel cover as a pattern to trim the floor plate if I can. I have the brake lines tweaked and installed, and the hydroboost/power steering pressure lines in. The return on the hydroboost and power steering should get done today. I have decided to go ahead with the simple tee method for the return now. I do not want to mess with the extra brackets to mount a different cooler, and filter at this time. I also have some reservations about the filter being a possible issue for returning fluid. If the filter was anything more then a course screen I am not sure what the result to the hydroboost or steering box would be with some back pressure. I haven't done enough reading on that to be confident it is a good idea. Although, I cannot imagine it would be am issue if you maintained a good schedule to replace the filter. There Just isn't any easy way to monitor the conditions and be sure the filter is in good shape with out perhaps a prefilter pressure reading. I would have to do more reading before I moved forward in that direction. I ordered a 1/2 inch brass PEX tee on Amazon and got it the next day for the same price Home Depot carries it for and didn't have to run after it.  I also had my wife pick up new return line and clamps on her way home from work yesterday so I can put the return together and not worry about it for a while. The swap is almost to the point of being about the same work as a clutch swap. A few little details, than pull the c6, flexplate, starter, and remove c6 specific components (cooler lines, linkage, jump park switch wiring) and the start installing the t19 parts. I am getting pretty excited, I had been most concerned with the portion of the swap that I nearly have done. All the changing parts under the dash and hood I had some concern with having the right parts. There was a bit of struggle with the clutch push rod. I have never worked with an adjustable clutch rod like this before and had thought there was an obstruction under the dash not allowing the pedal to return to the fully released position. It was also making the pedal bracket hard to get aligned and bolted down properly. I even removed the throttle lock and cable I had installed because I thought there was interference. Once I figured out I had the linkage adjusted too far the wrong way it all just started aligning quite a bit easier. One of those situations where a lot of time was wasted on a simple problem that I just couldn't get worked out. I do not like admitting to having missed a simple detail like that, but if it helps someone else I am glad to share. Perhaps today I can get the throttle lock back installed.

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

|

IMPORTANT NOTE:

The Delco saginaw to hydroboost pressure line did work (provided at the next startup I do not find an unexpected leak) and lay into the area in needs to pretty well. The only issue other then the slight thread modification discussed earlier was the power steering end has a 180 degree bend. In order to properly clear the reservoir and return (at least on the e150 power steering pump I am using) I had to open that bend up slightly. We are talking maybe 10 to 15 degrees. I just stuck a tight fitting Phillips head screwdriver down the end of the hardline for leverage and used my hands to force the bend open a bit. It just took a few attempts making small changes each time to get to the right amount of bend. You just need to be careful to not over bend the tube or kink it. It may not be an issue if a remote reservoir pump setup where used.

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

Re: The replacing of a c6 with t19. More than just the swap

|

Administrator

|

Glad it is going so well! Glad that fitting worked out. But I fully understand about the bend. Things are pretty tight right there and the bends have to be tweaked a bit to get things to line up nicely.

You did put the return from the steering box down the straight side of the tee - right?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Gary,

That is the first thing I hope to accomplish this morning. I talked some with Jonathan about it yesterday. He has his setup with the hydroboost returning inline/and power steering tee'd in and has had no ill effects noted. Jonathan's picture:  I will decide by how I can get the hoses to lay mostly stress free. I will try to document what I actually end up with, as well as, a few pictures of the Delco hose in it final orientation.

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

Re: The replacing of a c6 with t19. More than just the swap

|

Administrator

|

Yep, that's how I did Big Blue's, as shown below. But it does take some fiddling to get the hoses to lay properly.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

The pictures are nearly useless for this. I cannot get the right perspective/distance to do any good, and my bypass oil system hoses just make it more confusing. The steering and hydroboost are fully hooked up. Started the bronco up and let it idle for a bit. Steered left and right several times to ensure fluid was all through the system. I pumped the brake pedal a few times, but suspect it will need to fully bleed brakes again once my wife gets home to pump the pedal. The pedal currently has about zero pedal pressure to operate it, but I suspect that is all air in the system. I will have to report back once it is bled how it feels. I am going to drag out the t19 parts this afternoon and try to make sure I have everything before loading the bronco and parts up. If I do not have a call for work tomorrow I will haul it up to my buddy's to use the lift. Maybe, just maybe, by tomorrow evening this will be ready for a test drive. More likely that will happen Saturday. Updates to follow as they occur... Thanks everyone for following along to this point. I am posting everything with my phone so I try to proofread everything before posting, but I am sure some mistakes in grammer or keying make it past my quick proofing. Next question. Does anyone have a picture of this vintage t19 clutch master to slave hose routing path? Visually it looks like this thing is going to end up close to the manifold. The clutch line looks like it is missing a preformed bend in the center as well. Are they supposed to just be flexed around the firewall/floor to be installed? I see there is a clip on the hose that came off the wrecked truck, but I have no idea what the hose clipped to... the frame maybe? Any help with this would be appreciated. The f350 isn't currently on site where I can just walk over to compare.

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

|

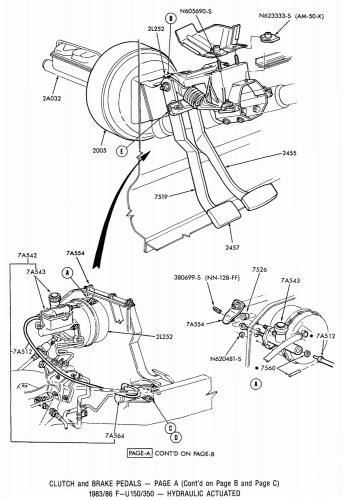

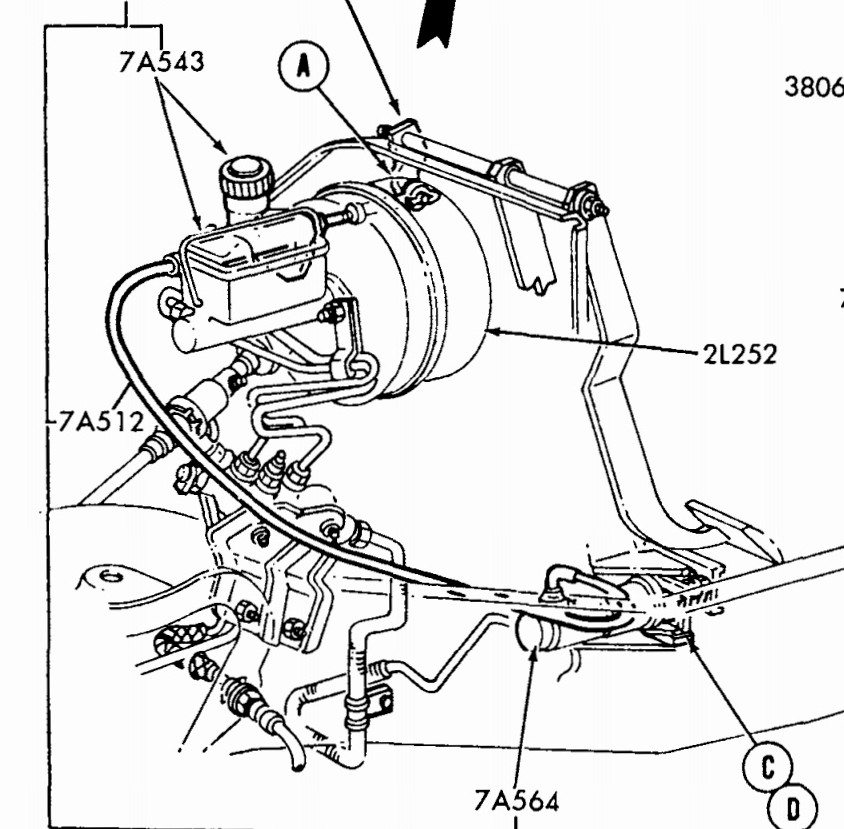

After lunch (while cooling off in the a/c) I looked through the documentation more and found a useful diagram...

I can see how the line can lay into the space now for the clutch, but what I still do not see is where the line gets clipped. The cut off used line with the slave cylinder had the clip hanging on it, but I just wonder where exactly the line originally would have been clipped... I am guessing the frame, but hopeful someone can verify for me.

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

Re: The replacing of a c6 with t19. More than just the swap

|

In reply to this post by IDIBronco

For what it's worth, I bent my lines by heating them with a propane torch and then using a pliers or wrench to pull on it (with the other end in a vice). I was able to move them around quite a bit without kinking the tubing.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

|

In reply to this post by IDIBronco

Update.

I am going to keep this short. A lot has been accomplished, but not much was able to be documented. I flat towed the bronco to my buddy's an automatic, and flat towed it home a manual. Not everything is done, but... the transmission, transfer case, flywheel, clutch and several other details are hammered out. The lift and transmission jack were all I dreamed. That c6 fought us on the way out, and the t19 just about slid right in by comparison. Fortunately, everything difficult is done and now it is down to small things I can knock out here at home again. I suspect I may take a couple of days off from the project.  Sadly, this is really the only picture I took today. It was just too difficult to balance everything and I was terribly dirty. My phone actually was overheating quite a bit and shutting itself off. It may not have been as much progress as I had hoped, but it definitely is enough to proud of what did get accomplished. More updates later this weekend perhaps. Happy 4th of July to all (tomorrow).

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

Re: The replacing of a c6 with t19. More than just the swap

|

Administrator

|

Congratulations!

That's a LOT better than having to do it on your back! Enjoy your independence day!

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: The replacing of a c6 with t19. More than just the swap

|

Administrator

|

In reply to this post by IDIBronco

That is something to be proud of! I've pulled and swapped enough transmissions and transfer cases on my lift to understand the effort involved. It isn't easy, but is FAR easier than on your back, as Jim suggested.

You are really going to like having a manual. I'm just not at all fond of the C6, and any manual is better.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

| Edit this page |