The replacing of a c6 with t19. More than just the swap

|

This post was updated on .

Well, I didn't document the attempt mainly because I had serious reservations it would work.

However, it looks like it will work. I am not going to lie to anyone and say it screws in like a new fitting would, but i can spin it in about 3 full threads with my fingers before needing a wrench to tighten it up. What I did was gently took the outside diameter down on the belt sander, using the flat platen part of the belt and allowing the nut to spin on the pipe, making very sure to hold the thread surface parallel to the belt surface. I took the O.D. down to .681 inches. Then I attempted to use a 18 tpi set of die jaws clamped in the vise, but that was never going to work. What I ended up doing was just simply using a small 60° triangle file like what you would use on a damaged thread. Just cleaned the threads up making sure to keep the file aligned to the threads. Just worked my way the entire way up the threads a few times and tried it. Only needed to do that about 3 or 4 times and it looked pretty decent.

It screws in and seats the oring now without too much issue. Had I really believed it would have worked out I would have done more pictures. This way the small mismatch of threads will act like self locking threads. I figure I will anti-seize the threads when I assemble it and call it good. No sense me running to buy another hose, or have something custom made when the threads do not need to be precise for sealing purposes. They strictly need to seat the oring, and resist the hydraulic force trying to push the fitting out. I am not recommending everyone do this method, but for me it will work. If not you will hear about the short coming when this gets fired up and driven again. Also, the new clutch just arrived so at least some of the parts are starting to show up. I decided to go with a 12 inch upgrade clutch by Luk from rock auto. I have 2 used clutches here I could use, but I think they will be held on hand just in case. One even is a puck style clutch, but I suspect it would be a bit too grabby for pulling a trailer. Now if the firewall reinforcement would just get here...

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

Re: The replacing of a c6 with t19. More than just the swap

|

Administrator

|

I toyed with the same approach on the fitting, and the only deviation would have been that I have an 18 tpi thread file. But you got it working, and you are right - it just needs to hold the o-ring in and resist the force pushing it out, which it will do.

On your new clutch, does the pressure plate bolt to your flywheel? That was the problem I had - the HD clutch came with an HD pressure plate that had a different bolt pattern. So now I have a new flywheel.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Gary,

You asked, so I decided to run out and verify. Now worried I had made a mistake in what I ordered.   It bolted right up, the holes lined up perfect. Now with a sense of relief that my purchase was correct I went ahead and got a few more information pictures...    The clutch disc was claimed to be a 12 inch upgrade from the stock 11 inch disc, while the fine print as well as the actual measurement show the disc is 11 7/8". The progress is slow today, but the firewall reinforcement is alleged to be here Tuesday now according to tracking. So perhaps I will shift focus and start removing parts under the bronco weather permitting tomorrow (drive shafts, linkages, drain fluids, remove the transfer case, etc.). It really depends on how much rain we get and how wet my area of yard is to work in. I can always open the transmission (t19) up in case of inclement weather to clean and change fluids. I haven't decided if I will put a rebuild kit in it yet or not. At the moment I am leaning towards not since I have a spare t19. If this one starts to give me issues (it is out of a low mileage, under 70,000 actual miles, local farm truck) I can order the kit for the backup and rebuild it and have it ready to change out when the need arises. The only issue is this is the 5.11:1 version (1983 460 truck) of a T19, the backup is a true idi version with the 4:1 ratio low gear. Jonathan thinks the skip in the 3 to 4 gear change might be unpleasant. I can compare it to the f350 when I get it together. The f350 weighs in at 7700 lbs empty. The bronco last check with tools and parts I have been hauling around was 5950 lbs. Even with the difference in gearing this thing should feel like a sports car (comparatively).

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

Re: The replacing of a c6 with t19. More than just the swap

|

Administrator

|

Glad your clutch fits!

On the gear ratios, Big Blue had the 5.11 1st gear version of the T-19 and 3rd was too low. It wasn't useful on the road. Once you'd dropped into 4th you really didn't want to have to go back to 3rd as the engine would be wound up tight at highway speeds. That was one of the reasons I wanted the ZF5. However, with the 460 there was little need to drop back to 3rd, even pulling a trailer. But still.....

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

That is the reason I am planning to avoid spending the time amd effort on the rebuild on the 5.11 t19. I figure I will end up running the other transmission as soon as I can, or saving up to try to add one of those fancy torque splitting overdrives...

Provided I can possibly work with the wheelbase and short rear shaft. MUCH more research is needed before I pony up the coin for that plan.

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

|

In reply to this post by Gary Lewis

Did BB have 3.55 gears with the 5.11?

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

Re: The replacing of a c6 with t19. More than just the swap

|

Administrator

|

Yep, BB has 3.55 gears. And that T-19 with 5.11 gears. And 33" tires. The calculator page (Documentation/Driveline/Calculator) says with the T-19 the engine was spinning 4227 RPM @ 65 MPH in 3rd. But with the ZF5 it'll only be spinning 3802.

And, I get the 5.72 1st gear and .76 5th gear.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

I spent some time crunching numbers on the percent change in gearing on different arrangements of zf/T19/T19 w/ torque splitter.

I will probably make a quick spreadsheet to more logically show the information. Just pretty neat to see the comparisons side by side. I was able to run and get the flywheel ground locally this morning.  A very valuable trip. The price was pretty great, and the information I got about installing the pto onto the transmission and shimming it was invaluable to me. The person working on transmissions there just started a conversation while I waited and I thought to ask as I knew it would be regular everyday information for him. I even ended I headed home with the correct shimming gaskets all for cheaper then the local parts house could get it done in 3 days... Maybe an hour and a half invested to drive there and wait. A very good investment indeed. Allegedly the firewall reinforcement is out for delivery a day early so perhaps I can get that installed this afternoon. If everything would go just right, I could get the pedals, brakes, steering column, interior wiring (minus clutch switch), hydroboost, and power steering all buttoned up before I give it up today. That's a lot that has to happen without issue though. We will see how early the reinforcement gets here. I do not really want to start removing the parts underneath until I have all of this back together. Make it more like a clutch change then a swap at that point. This is all the tedious stuff in my opinion, plus I am still strongly leaning on hauling this up to a friends to use a lift for the work underneath. Updates hopefully to follow through the day...

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

|

I ran the numbers many times between the T18, ZF if I could find one, NP435 and the TQ Splitter.

When I found the NP435 and having a lower 2nd gear, dose not feel it, than the T18 that was the way to go with the over drive. I could not find a ZF and with the AA OD ($1600) and drive shaft ($330) I am under $2000. I don't think you could find a ZF and all the parts (I have linkage clutch) for $2000. I would like to know how many use the syncro granny in the T19? Most of the time you are using it to take off from a stop so would not need the syncro granny. With the little bit of driving I have done since the OD install if I was pulling heavy loads most of the time I would go with a lower (higher number) rear gear over the 2.75 I have now, may be a 3.25 or 3.55? I have not run them numbers as I don't plan on pulling heavy loads most of the time LOL. I will have to go back thru was this a 4x4 and what does the PTO work? was PTO on the C6 and how was it installed? Dave ---- edit: I see it is a 4x4 Bronco did it have a PTO and for what?

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

Re: The replacing of a c6 with t19. More than just the swap

|

Administrator

|

In reply to this post by IDIBronco

Why make a spreadsheet when we have one that should do it nicely: Documentation/Driveline/Calculators. There is a place up top where you can input several variable, including OD ratio. The transmission ratios are already in it.

And, if you need something else please tell me. The Overall Gear Ratio section was put there for Dave if I remember correctly, so we can tune and tweak it to make it do what we need.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by FuzzFace2

I do pull some decent loads with the bronco regularly. I haul quite a bit of firewood and pull a few different trailers to accomplish it. I have been known to pull a car hauler and vehicles as well.

Not sure that the notes are easy to follow along, but I intend to redo on the computer to make it a bit easier to follow (I really was just running the numbers for myself, but I decided to post it). Please ignore my water stained shop notebook. At the moment the 5.11 ratio with the torque splitter looks pretty promising to me. Pretty consistent rate of gearing change even compared to the ZF options. The pto was previously mounted on an f350 with a t19. I pulled it off the transmission at the scrap yard as well as the front d60. I sold the d60 a few years ago, but the pto has been waiting for a project to use it on. I have a couple of ideas on how I want to use it, but that part of the project is not yet ready to go public. I intend to go ahead and install the pto with the transmission, but what it is supposed to run may wait until the next phase. I also have the matching driveshaft that was with the pto. In it's previous life it powered a remote hydraulic pump, so it should be "easy" to adapt to power anything.

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

|

In reply to this post by Gary Lewis

I have a lot of experience with excel. Just was something that would be easy for me to crank out myself. Not trying to reinvent the wheel, just easy to do.

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

Re: The replacing of a c6 with t19. More than just the swap

|

In reply to this post by FuzzFace2

I don't know what his use is, but when I had a T-18 in my CJ5 I had a lot of opportunities to use a synchro 1st. Down shifts when running out of power on a hill or in a mud hole just didn't work. And losing all your momentum and starting from a dead stop wasn't always a good option. On the other hand, it was never an issue with the NP435 in my '85 F-250. like you say, I almost always was already stopped when I wanted 1st gear. It's all in how the vehicle is used.

Bob

Sorry, no '80 - '86 Ford trucks "Oswald": 1997 F-250HD crew cab short box, 460, E4OD, 4.10 gears "Pluto": 1971 Bronco, 302, NV3550 5 speed, Atlas 4.3:1 transfer case, 33" tires "the motorhome": 2015 E-450-based 28' class C motorhome, 6.8L V-10 "the Dodge": 2007 Dodge 2500, 6.7L Cummins |

|

In reply to this post by IDIBronco

While waiting for my parts to arrive I went ahead and pulled the steering shaft between the steering box and column (intermediate shaft?). I had read before where the later shafts are a direct upgrade replacement. The shaft in my 91 parts truck was already half way removed (column out) so all that needed to happen was remove the bolt at the steering box and it was out.

1991 steering box shaft end  1985 steering box shaft end The newer shaft is clearly in better shape. It appears the leaky old powersteering pump had done it's damage on the rubber, as well as age and use in the 1985 shaft. The rubber and general condition of the 1991 shaft look to be quite a bit better.  1991 shaft column end  1985 shaft column end The boot is torn and damaged on the 1985 shaft. The 1991 looks to use a u joint with sealed beatings, no rubber boot to loose. I am sure you probably can even get a replacement for the u joint, though I have not looked for it.  The obvious difference in the two shafts is the section that overides the smaller section are opposite on the two shafts. The newer shaft has the overriding section at the top (towards the column). Makes sense in my head because it would be less likely to accumulate anything between the sections because the material wouls have to go uphill to get there. While the old style anything that gets on to the upper shaft section can just run down and get between the sections. Also, the bolt at the column end of the shaft is a better design on the 1991. It uses a welded on style or threaded hole (I haven't looked close enough to see which). The 1985 used a clip on bolt with a nut on the back side. I personally spent 25 minutes trying to find the nut when it came loose from the bronco due to this design. The 1991 design the bolt just stayed in the hole and I was able to reach up and pull it out. Either way, I am swapping the 1991 into my bronco as it does look like a nice "free" upgrade from the parts truck.

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

Re: The replacing of a c6 with t19. More than just the swap

|

Administrator

|

Yep, the later lower steering shaft is a better design, all the way around. That's what's going in Big Blue - now that I found the ones I had stashed.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Well, as predicted here... The bracket fought me some. I finally figured out the trick for me was to get some bolts and fender washers to pull the bracket into the firewall tight. It made the bracket/firewall form themselves together. Then drilled the 5 holes and bolted it up. With only one set of hands pictures where not very possible. It is a pretty tight space to work in if you aren't as thin as you used to be, or as flexible. The reinforcement is in though. So good progress. Enough of a break drinking water and posting pictures... Back to work.

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

|

Well I made some progress, but there were problems.

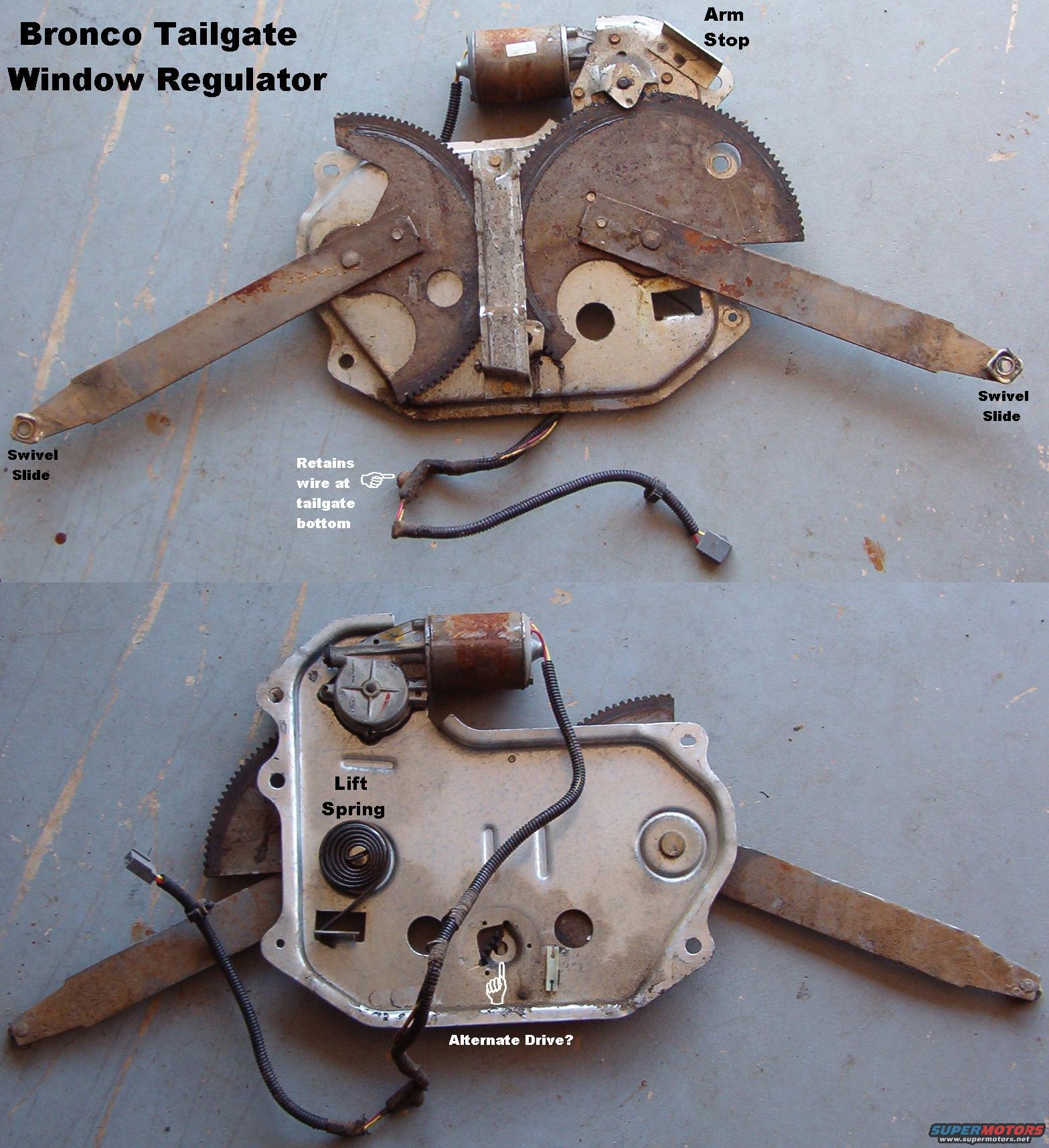

I was able to get the clutch master all hooked up and the brake master mounted. The pedals are in and the column is ready to go in.   It took a while to get the wires routed around the pedals and column. I had to relocate where the wiper delay box was located. I was running out of daylight and I decided to go ahead and call it and load the parts and tools in the bronco and close it up... It was at this time the window motor decided to no longer function. I got the test light out and had power to the tailgate, I had power past the latch switch so i went ahead and cut the wires to the motor and used the cordless tool battery pack to jump the motor and nothing... I have been getting fed up with fighting with the rear window for a while now. My rear door switch died and I have been living with just the dash switch operating the window for a while now. It would not be a big deal if the weather predicted where dry, but I could hear thunder already in the distance. So I drug over a rust tailgate I picked up a couple years ago to try something on. I have been planning to make a writeup on this particular project, but I needed it now to get the window up and do away with the wiring issues. I had already made the modification so i just had to swap the parts in.  What I had done on the tailgate a few years ago was pull the window regulator out (it was already mising the motor when I got that tailgate). I had seen a Steve83's picture a long time ago where he speculated that you could easily modify a bronco to be a manual rear window.  (Steve83's image) While this may be less desirable for some people, it had me intrigued. I had just pulled a window regulator out of a 1979 f150 I parted out, and removed the window crank mount and installed it onto the bronco tailgate window regulator. It is just a couple rivets and a small tack weld to hold it in place.  I had already used the free rusty tailgate to figure out where the operator hole needed to be placed. So all I had to do tonight to make the change was remove my power regulator, and install the manual regulator and drill a hole. Reinstall the glass and I am able to get the window up and down. I can easily go back to power in the future if I choose to, I just have to get a new motor and repair some wiring I clipped in testing tonight.  I am pretty pleased with the manual window. I think I will just leave the window handle screw out and keep the handle in the cab. If I want I can even put it in my pocket to be able to open the rear window if out shopping, without climbing in the cab. I had invisioned eventually building a rear tire carrier for the bumper that would lock and block access to the window handle. This concludes today's work, off to grab a bite to eat and get cleaned up. Fortunately, I did beat the rain with getting the bronco closed up.

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

|

That’s handier than hip pockets on a t-shirt! I like it!

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

Now if I could figure out an operator handle like the older jeeps or the blazers used that would fit where you install a key to be able to operate the window. I do not have any of those type of parts to compare with the dimensions and spline count on the bronco handle shaft.

I do not know if those splines are similar for all brands.

1985 Bronco

6.9 IDI hydroboost brakes 8 Lug coil sprung D44ttb 10.25 3:55 warn classic bumper 8274 warn winch Saginaw Conversion 1986 Ford F350 "Dump Truck" 6.9 IDI T19 8'x12'x4' hydraulic dump bed front mounted tow bar 1981 Ford F350 "Welding Truck" 300 I6 T18 Welders bed with hoist onboard air |

Re: The replacing of a c6 with t19. More than just the swap

|

Administrator

|

In reply to this post by grumpin

Yes, that's cool! And you could put a plastic plug in the hole to give it a bit of a finished look.

So, could you have both electric and manual?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

| Edit this page |