The Deuce Build Thread

|

Administrator

|

Yes! I could not have done what I've done or am doing w/o the lift. I tried doing things like you did and gave up. I was just way too tricky and difficult. Now, with the lift and a tranny jack it is not too bad.

Now for what I fear is going to be the next "challenge". The t-case is going to hit the floor of the truck. I ran into that on Dad's truck w/the E4OD. You can read about it starting here, but the bottom line is that I had to cut a piece out of a donor cab and patch the floor in Dad's cab. And there's some info on the E4OD tranny crossmember here. You do have that crossmember, right?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Gary, thanks for the heads up. I'll trim that little block off the TC before doing anything else, and see where everything falls. With this particular truck, I'm not at all opposed to the BFH approach, so we'll see if I can attack it that way. I really need to get the truck rollable again today. My shop is full of equipment and my other project car, and so I can only get the truck halfway in. So I can't lock it up. I live in a pretty good neighborhood, crime-wise, but it still makes me nervous. Yes, that looks like the crossmember I pulled out of the '95 donor truck. I'll have to go look at it and figure out which way round it is installed. It looks like from your photo that the 2-piece end is drivers and the part that goes on the outside of the chassis is passenger. As always, thanks for the input!

81 F150 Flareside, Edelbrock Pro Flow4 FI, hydraulic roller 351W, E4OD, 4x4, BW1356

92 F150 RCLB 351W E40D BW1356 mostly stock |

|

Administrator

|

Good luck getting it rollable. I'd be nervous too!

And yes, the part of the crossmember that goes outside is on the right/passenger's side.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Pete Whitstone

That’s great!

Good thinking on getting it up and in there. Those RV jacks are a good idea.

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

In reply to this post by Pete Whitstone

Transfer case is on. That was just as much fun as the transmission before it. At least it was somewhat lighter and I could actually heave it around a bit. Not that there was much room to.

Lesson 1 - when installing or removing the TC, drop the gas tank first. Getting it installed started with pretty much the same steps as the trans - build a cradle. I was running low on lumber so metal became the medium of choice. Here's the initial design.  Which fits on the case like this.  And when flipped right side up, sits like this.  My initial plan was to use some lumber underneath it, but that seemed sketchy, and besides, that meant I had to raise it another 1.5 inches before I could get a jack underneath it. So I added another metal support and used some 16 ga sheet for the bottom instead.  With that sorted, I could start the install. Like with the trans, I used wooden blocks on each side to get it up onto the jack.  From there, it was just a game of what interferes with what. The motor that activates 4wd and low was not going to play nice with the gas tank, so drop it. The gas tank is still interfering with the TC itself, so drop the tank down and try to scooch it rearward an inch or two... still no good, well I guess drop the $%#$ tank... finally got it installed. Sheesh. Now I could look at installing the crossmember. Took a trip out behind the shop to look at the donor truck chassis to see how high up those holes are.  Pretty obvious how low the sun was getting to be by this time. The bottom two holes show that the crossmember is not mounted all that high in the chassis, which was good. There was a brake-line-looking thing running along the chassis on the passenger side on the 81 that is not present on the 95. I don't think it's actually a brake line, I think it is probably a gas tank vent line that runs up to the charcoal canister or something. I was able to bend it down so it runs just underneath the chassis in that area, to make room for the crossmember. I punched the 2 lower holes and got the crossmember bolted in place enough to support the trans/TC, so now the truck is rollable again and I can get it out of the shop. I had hammer-massaged the areas I thought I would have clearance problems in - the area Gary pointed out above. But after the crossmember was in place, I found that I probably could have gotten away without it. As it is now, I can pass my hand through the area - just barely. So maybe an inch of clearance. I have 4 more bolt holes to drill to finish the crossmember installation, and 3 of those are "blind", in that I will be guessing where the hole has to land. OK maybe better than guessing, I will be carefully measuring, but still, it would be easier if I could see exactly where they needed to go. I don't think there is room for the gas tank up there with the TC and activation motor in place. I don't know if the later trucks had a modified gas tank, or maybe they didn't have SWB standard cab 4WD trucks by the time the motor came out, so the gas tank sits further back, I don't know. Some research is needed to figure out if I need a different gas tank, or if it's safe to "clearance" this one. That is the first of a long list of items that need addressing before the truck can be driven again. That list looks like this currently. - Gas tank - Crossmember bolts - Shift linkage - Install factory manifolds - Modify exhaust system to use factory manifolds - Extend or replace trans cooler lines - Install trans cooler - Get correct length drive shaft made (33.5") - Install front drive shaft (new u-joints too) - Rebuild 9 inch with 3.55 gears and posi - Install 4x4/Low switch in cab - Install new longer speedo cable - Install trans controller computer - Wiring for 4x4 switch, computer - Install TPS on carb for trans control computer - Install wiring harness for trans control computer I am probably forgetting some stuff, I'll edit the post as I think of it.

81 F150 Flareside, Edelbrock Pro Flow4 FI, hydraulic roller 351W, E4OD, 4x4, BW1356

92 F150 RCLB 351W E40D BW1356 mostly stock |

|

Administrator

|

What transfer case do you have? I didn't think about yours being that different, but it is. Sorry you beat up your floor. But it is good to have that ~1" of clearance since the mounts do allow for movement.

Anyway, you got it rolling. Well done!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Borg Warner 1356, same as you were installing in that thread. I didn't beat it up too much, and it's under the seat, so no one is ever going to know. Besides, "beat up" matches most of the body panels!  One difference I saw between my cab floor and the one in the pics from your thread is, for whatever reason, the raised area of the floor fell mostly behind the cut-off tab on the TC on my truck. What clearance problems there were going to be were right on the edge of where the floor came down and turned back to horizontal towards the back. In your pictures it looked like that cut-off-tab was back a little further than it turned out to be on mine. In other words, more into the area after the floor turned horizontal. Speaking of mounts, I had to order a new one this morning, as the cheapo one I got from Rock Auto or eBay or wherever the heck I got it from, broke. The entire thing was coated with a black paint-like substance, which made spinning the lower nut on somewhat difficult. Not cross-threaded/wrong thread difficult, but a little difficult. Anyway, the mild amount of force required to overcome it, broke the stud out of the tack weld that held it in place. Piece of junk. Yeah I could weld it more fully, and pour water over it before the weld heat starts melting rubber, but why? If it's that poorly constructed in the first place, it won't last long anyway. I need to remember to buy higher quality parts when I go shopping.

81 F150 Flareside, Edelbrock Pro Flow4 FI, hydraulic roller 351W, E4OD, 4x4, BW1356

92 F150 RCLB 351W E40D BW1356 mostly stock |

|

Administrator

|

Interesting. I wonder if the different engine moves things fore/aft a bit. But both cabs are regular 81's.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Pete Whitstone

So that was the list to work on this month. I'm happy to say that list looks like this now: - Rebuild 9 inch with 3.55 gears and posi - Install 4x4/Low computer under dash I was able to knock out most of the original list. I have to get the 4x4 controller box mounted under the dash, then put the instrument cluster back together. It's going to be a tight fit to get that box under the dash, as it's piggybacked onto some other items - a small fuse block, a relay, and some power lugs. However, with the instrument cluster on the floor, I was able to start the truck, fill the trans with fluid, and take it for a quick test drive. Only about 2 miles, but it was enough to verify both the trans and the controller are working fine. Got it up into 4th, verified the kick-down function works, and so on. This thing shifts HARD! Not unpleasantly so, but it definitely does not muck around when it's time to grab the next gear. Getting the initial test drive out of the way is a huge relief. With the 3.08 gears still in the rear, it was loping along at about 1200 rpm when I was doing about 45. That will go up with the 3.55 gears of course, but I think overall I will get better mileage with the 3.55's and overdrive than I have been with the "straight" (1:1) drive and 3.08's. Since it rained and the ground by my shop was wet, I did put it in 4x4 mode and moved the truck a few feet. Impossible to tell if the front wheels were actually powered or not though, I guess I need to get it up on jackstands to prove it's all working. I threw it in Low as well, that produced some surprisingly loud mechanical clunks from the transfer case, but it did appear to change the ratio to something lower. More to come. I'll get pictures when I get it all back together.

81 F150 Flareside, Edelbrock Pro Flow4 FI, hydraulic roller 351W, E4OD, 4x4, BW1356

92 F150 RCLB 351W E40D BW1356 mostly stock |

|

Administrator

|

That is excellent news!!!

Man, that has to have been a huge relief. Well done!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

loud clunks make me nervous. hearing a little actuating noise is one thing. i think you said it is the 1356.

that transfer case has a rather weak link being the oil pump/pickup assembly. |

|

In reply to this post by Pete Whitstone

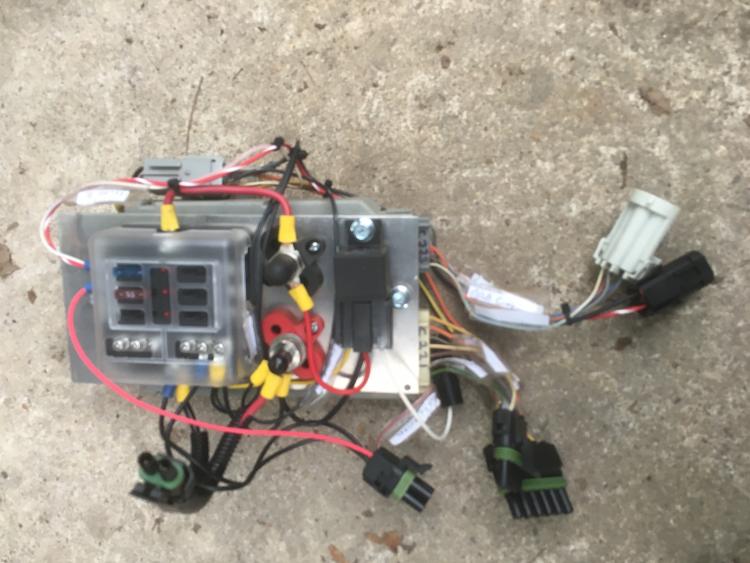

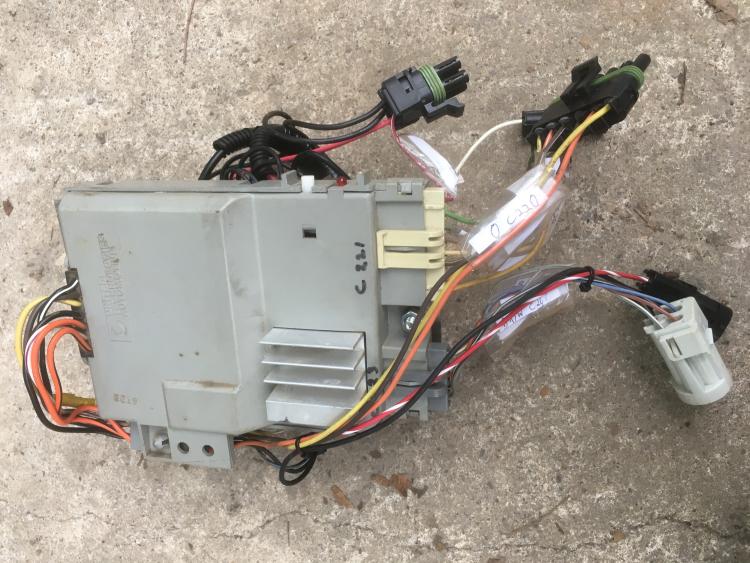

And here they are. Got the truck put completely back together. Here is the front and back of the 4x4 controller motor and power distribution stuff. I will be using more ports on that, as I get the motor converted to EFI.   Built a bracket to mount it up under the dash, here are some shots of it in place.   Bundled all the wires up as neat as I could, and put the dash back together.  It's pretty much the way it came out, except for the 4x4 switch now occupying some of the cubby.  Finally, the transmission controller was mounted into that little area on the left of the glovebox.  And I forgot until now, I was able to use those 2 speedo cables I had, putting a VSS in between them under the brake booster - shout out to Gary who sent me one! The other end of the cable, that had that big 7/8" screw on thing, was handled with a $15 ebay GM to Ford converter. Not sure yet if the gears I have will read accurately, I think they are 7/17 and should be in the ballpark. Once I rebuild the 9 inch and install different gears and a helical worm gear diff, that will about wrap up this phase of the project. Next up is the motor. The general plan is this. - Starting with the '95 351W hydraulic roller block - 408 stroker kit - Aluminum heads - Mild cam - Edelbrock Pro Flow 4 EFI system - '95 serpentine belt drive and accessories But I shouldn't have to have the truck down very long for that, since I'm starting with another engine. More on that when the project starts.

81 F150 Flareside, Edelbrock Pro Flow4 FI, hydraulic roller 351W, E4OD, 4x4, BW1356

92 F150 RCLB 351W E40D BW1356 mostly stock |

|

Administrator

|

Well done! That looks great!

I assume the Pro Flow has a computer, so where is it going to be mounted? I ask because I'm looking for the best spot for my EEC V controller to go, but think it'll go roughly where your 4x4 controller went, which is where Ford put it for several years.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

i only had one experience with the pro flow 4. that was last year doing a 78 vette. 350/350. classic edelbrock format. we NEVER got it to work correctly. many hours on the phone with edelbrock tech support. they tried to control it from internet. wound up boxing it up and sending it back to them. they sent another complete unit and we had different fails. returned that and used a performer rpm and an avs2 carb with an hei. voila! ran like a dream. we never found 'a' problem or a cure. handheld controller seemed to not communicate with ecu reliably. tech support was good, and service was also however we NEEDED both and still had to go another direction because the customer lost patience. understandably so.

|

|

In reply to this post by Gary Lewis

Not sure yet. I imagine it will have to go somewhere under the dash to the right of the gas pedal, maybe above the hump, but under the dash. Somewhere near the HVAC controller, I am thinking. I'll have to get it and see the actual size of the computer. I think it's pretty small, I am assuming it is the black box at the top left of this image. https://static.summitracing.com/global/images/prod/xlarge/edl-35950_xl.jpg If so, it looks like it's not much larger than a pack of cigarettes.

81 F150 Flareside, Edelbrock Pro Flow4 FI, hydraulic roller 351W, E4OD, 4x4, BW1356

92 F150 RCLB 351W E40D BW1356 mostly stock |

|

In reply to this post by mat in tn

Thanks for the input, Mat. Not what I wanted to hear, but I'd rather know now. Looks like there are 14 reviews on Summit's website for this particular unit, under 3 part numbers. 12 of the reviews are 5 star, and 2 are 4 star, so your experience doesn't seem to be a common one. I wonder what the differences are between the Chevy and the Ford units? Might only be the intake manifold.

81 F150 Flareside, Edelbrock Pro Flow4 FI, hydraulic roller 351W, E4OD, 4x4, BW1356

92 F150 RCLB 351W E40D BW1356 mostly stock |

|

i certainly wish i would have learned the cause or causes to report on but it seemed to be multiple issues. being an ecu we ran proprietary grounds to avoid irregularities. in some cases, we had injectors on one side and other cases it would revert to the other side. always proving the hardware yet it always seemed to be in the software or controller. it ran pig rich and sounded like a harley, not the good ones!

|

|

In reply to this post by Pete Whitstone

I spent part of today trying to dial in the trans controller computer a bit. I left the glovebox door down and paid some attention to the small display on it. The "home" screen on it shows MPH and a few other data items. Since I wasn't sure where I would land with speedometer accuracy, I used a GPS speedo app on my phone to find actual ground speed.

What I was seeing was the display on the trans controller making sudden and unpredictable changes in speed. It would show 15 miles an hour (roughly accurate) then suddenly jump up to 42. This of course would make the trans lurch because it would think it needed to upshift. The needle on the mechanical speedo was a bit jumpy, but didn't display any such antics. I swapped in another VSS, the kind in the middle of the speedo cable, near the brake booster. Same result. I checked all the wiring, checked that the VSS's were spinning freely, but the problem persisted. Finally I decided to try to get the VSS to fit into the TC tail shaft housing again, and see what kind if reading it gave. That would eliminate the possibility of problems with the speedo cable or the mid-cable VSS's. After a bunch of messing around with the interfering seam on the gas tank, I finally got it to slip into position. Then I made a new cable to go up to the front where the pick-up point for the speed sensor was. I determined that I can probably get the long single-piece speedo cable in the end of the VSS without interference from the gas tank, but left it off for now. Another test drive revealed a much more predictable speed reading. It still jumped around a bit, but from like 54 to 58... not enough to make the trans want to shift or anything. Still more than I think it should jump around though... if these things are designed to handle cruise control, I would think they would have to read rock steady. One thing I had to do to get the speed in the ballpark was to play with the configuration settings on the trans controller. When I started off, it was reading about 20% low - it would think the truck was doing 35 when it was doing 45 for example. This made it delay the shifts, since it didn't see that the speed it wanted had been obtained yet. The computer has the ability to input a bunch of different things - axle ratio, tire diameter, drive and driven gear counts and so on. For now I just played with the "sensor pulses per revolution" and by reducing it from 8 to 6, got the speeds in the ballpark. I need to fix it right by setting it back to 8 and entering all the other stuff correctly, but that's for another day. I would need to change the axle ratio anyway after I put the right gears in it. The trans seems to be working flawlessly, now that it doesn't think the vehicle speed is jumping around too much. I'm going to call Baumann/US Shift and see if the VSS wires are sensitive to being run with other wires and may be picking up noise. I might have to reroute them if that's the case, but the manual didn't say anything about any sensitivity there.

81 F150 Flareside, Edelbrock Pro Flow4 FI, hydraulic roller 351W, E4OD, 4x4, BW1356

92 F150 RCLB 351W E40D BW1356 mostly stock |

|

Administrator

|

I saw something similar on Big Blue's speed control. I was running that VSS I sent you, meaning in the middle of the speedo cable, and couldn't get the speed control to be as stable as I wanted. So I switched to the VSS in the output of the transfer case.

But, at the same time I discovered that the speedometer drive gear in the t-case was slipping. So I fixed it and took the truck out to test it - much improved. But I don't know if it was the VSS or the drive gear, or both. However, I can't imagine that the output of the VSS in the middle of the speedo cable is as stable as that of the VSS in the t-case. That long, skinny speedo cable probably has some whip to it. Anyway, you are making progress!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Pete Whitstone

I decided to go with an electronic speedometer rather than a mechanical unit. The 92" cable I switched to, rather than the 2 piece, came a few inches short and so I would have had to deal with extending it somehow. And I am about to change the rear end ratio, and would have to deal with changing the speedo gears... and in the future I may want larger tires... with all those things considered, it was easier just to install an electrical one rather than mess with cables and gears. I got basically the same speedo as I had, just the electrical sender version. So now I didn't need the speedo cable (I've got a small collection of them, if anyone needs one), and I removed it from the truck. However, that left the end of the sender open, and I didn't like that. So I fired up the lathe, starting with a piece of .625 aluminum, and turned an analog for the cable end. Here it is in mid-development.

After finishing it and parting it off, I added the O-ring from the speedo cable and installed it.   Plugged it back into the transfer case tail shaft housing and called it good. Now the sender should not have any whip or resistance to make it read weird, but I haven't had a chance to test that yet. Instead I dove into getting the pumpkin out for the new gears. Got it out and on the bench.  And started breaking it into its subcomponents.  The gear oil was smelly and thin-chocolate-milkshake looking. Probably some water in there. Teardown went well except for the yoke. When I pressed it out of the pinion carrier housing, parts of it stuck with the yoke. Specifically, the bearing, front seal, and what I think might be the oil slinger. This is what it looks like after I tore off the seal.  The triangular thing on top is what's left of the bearing. The weird thing is, at this point the entire thing appears to be one solid piece. I can't find a parting line anywhere on the thing. I know the bearing comes off, but I can't find where they separate. Got to do some more research on that. I'll start on the assembly of the rest tomorrow.

81 F150 Flareside, Edelbrock Pro Flow4 FI, hydraulic roller 351W, E4OD, 4x4, BW1356

92 F150 RCLB 351W E40D BW1356 mostly stock |

| Edit this page |