Dad's Truck Build

|

Administrator

|

Yesterday I got all the bits and pieces to put the patch on the floor:

SEM 39747 Multi-Purpose Panel Adhesive: This stuff has a 90 minute working time, 4 hour set time, and 24 hour cure timeDominion Sure Seal's Primer/Coating Cold Galvanizing Compound to paint the patch with before installing and after I media-blast it. But, I'll have to tape the mating surface so the adhesive is bonding to bare metal. This was John's recommendation, and provides both corrosion protection as well as "tooth" for the bed liner he will shoot on.Marson 3/16" stainless rivets with a grip range of .062 to .270".So the plan for the day is to go up to John's and borrow the "gun" for the adhesive, come back and blast the patch, mask and paint, and while it is drying strip the paint off the mating surface on the floor. Then I'll mix the adhesive spread it on, run the screws in, and then pull them one at a time, drill the hole to specs, and install the rivets. And then I'll have to clean up the mess! There will probably be adhesive everywhere, so that will take a bit of cleanup.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

This post was updated on .

The labyrinth (?) nozzle should do all the mixing for you.

Instructions should say to discard the first x inches of bead to ensure proper mixing/ratio. Or something like that.... So glad to see you getting closer and closer to your ideal interpretation of Dad's Truck! Progress is good.  ETA, this is good hand cleaner.  Be sure to get the Special Ultra. It smells like green apples.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

Yes, that nozzle should mix it well. And, I now have the gun, have sanded the parts to bare metal and am about to do the deed.

HOWEVER, John said my plan to pull the patch down with screws and then swap the screws out for a rivet, one at a time isn't good. I need to leave a little space between the two pieces of metal so there is some of the epoxy between them. Given that, I'm going to run a few of the screws in just to align the patch and then start installing rivets. But, I won't tighten them down much and certainly won't "pop" them until tomorrow after the epoxy has set up. Sound like a good plan?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Good to me.

I'd imagine someone who does this for a living would have an air tool that punches the hole and creates a dimple at the same time, leaving the proper film thickness of bonder.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

John doesn't have fancy equipment like that. But, he's sure done a lot of body work and knows his stuff.

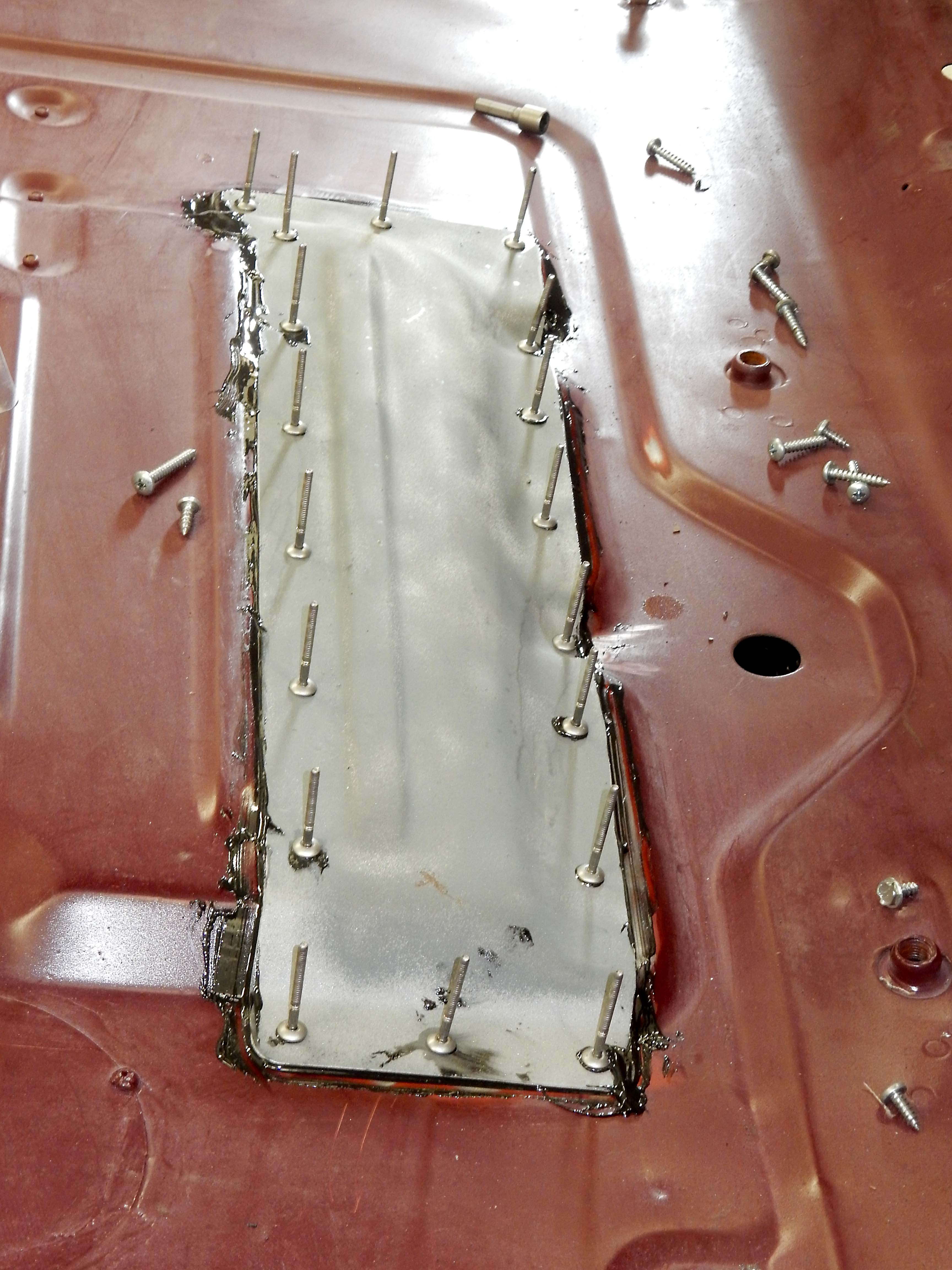

Ok, the floor patch is in place and it looks like the process of snugging the rivets up worked. I started in the center and worked to the ends like torquing a head. And I got some of the goo squeezing out all 'round. But then I went back to the center and made another pass as the rivets there had gotten loose. But after two passes all were snug and I cleaned things up as best I could. Here are some pics for your enjoyment.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Fine work and well documented!

|

|

Administrator

|

Jim - Sorry, I missed this. Yes, the nozzle did mix it nicely. And I was told to run 2" of stuff out before installing the nozzle. What it didn't say is that you'd better have a strong grip. I now understand why there is a pneumatic applicator. I broke out in a sweat getting the adhesive in place.  As for the hand cleaner, I may give it a try. I have been using Permatex's Grease Grabber, and even bought the dispenser. But the only way it works well is to get a gob of it in the palm of your hand and add a squirt of Dawn. That combo works pretty well. But, for the price I'm not impressed. Thanks, David. I really wanted to document this as I went 'cause I suspect someone else is going to want to put an E4OD in their 4wd Bullnose and I thought they should know one way to solve the floor problem.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

For general filth, I typically reach for the orange-flavored slime with pumice. It gets average dirt out of my fingerprints without much effort. For the really-greasy grime, I use plain Gojo (or almost any other brand) of waterless cream. In either case, it's critical to apply & work the cleaner BEFORE any water; and use a fingernail brush, fingernail scrubber, or non-stick pot scrubber to break up the heavy spots. Rinsing while scrubbing the last spots usually results in hands that don't look like they've been grimy in weeks. Then I follow up with Dawn to remove the odor of the other cleaners. |

|

Administrator

|

In reply to this post by Gary Lewis

Gary,

The handcleaner was an afterthought when you mentioned how messy the the panel bond might be. While i'll use Fast Orange w/ pumice or regular Goop for grease, in my work when I get caulk, paint or most glues on my hands that little tube in my truck is very convenient. Of course nothing on the planet will remove polyurethane glues like Gorilla glue or PL Premium construction adhesive. The pneumatic gun is almost twice as expensive as the manual one and doesn't work at all if you don't have a convenient source of air. So, there IS that... When you mention John doesn't have a need for fancy tools, if he is using panel bond on any visible parts he's surely using a punch and flange tool already. I was suggesting that the punch die could incorporate a countersink. Automagically providing proper film thickness and making it almost impossible to squeeze it too much. Hmmm, maybe this is my next million dollar idea. (no chin scratching or light bulb emoticon) Anyway, it looks great and I'm sure you're glad to get past this last hurdle on your way to mating cab and chassis. Congratulations!

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

Jim - I like the idea of the punch die having a countersink. Go for it! Invent it.

But I didn't mean to imply that John doesn't have a need for fancy tools. Just that he doesn't have them. He didn't even have a rotisserie until I came along, but I took mine up and he is still using it - which is great 'cause I don't need it as he does my body work. As for the hand cleaner, I carry a tube of Fast Orange in my tool box for use when out and about. I just need to find the "right" cleaner for the shop. Years ago I won a wall-mounted dispenser for Go Jo, but while it was convenient it leaked and there was always a mess under it. So I thought the Permatex dispenser would be the way to go, but I'm not too happy with it. Maybe I'll go back to the 2 gallon plastic bottle with a pump on top.

Anyway, thanks for the congrat's! Yes, I am really looking forward to getting past this last hurdle. In fact, when John comes down and applies the bed liner under the cab I'm taking a break on Dad's truck and moving on to Big Blue. (If only I knew exactly what to do to BB.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

In this house & shop, I mounted all the soap dispensers over the sinks so the drips either go in, or fall on the tray to be soaked into the sponge or brush for later use. I have a wall-mount hand-cleaner dispenser, but those bottles are too expensive, so I didn't mount it here. I use a fastorange pump jug or a big bucket of Gojo/Goop/etc. |

|

Administrator

|

Got the rivets "popped" and then the patch primed today. And, tightening/popping the rivets didn't move the patch whatsoever. In fact, I think the floor is now slightly stronger since it has the 1" overlap around the patch, with both adhesive and the rivets holding things in place.

Here are some pics, starting with before painting and then after painting.   And here's the patch from above, after painting:  Last, here's the clearance, although before I torque the body mounts down. There's probably 1 1/4" there, although it is really hard to measure.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Nice job!

What kind of puller did you use to pull the rivets? Those "Marson" rivets look similar to the Cherry brand I used to use on aircraft, but not as strong. The Cherry locks could be used as structural, although some of the old salts I was around did not use a blind rivet unless you absolutely, positively could not get a solid rivet in there. An old boss of mine could get his assortment of bucking bars in some amazing places!

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

Administrator

|

I have a Craftsman HD rivet puller. When I got my first blast cabinet, an Eastwood, it used pop rivets to hold it together. But those were serious rivets and my little puller wouldn't do it. Hence the HD one But it took everything I had today to pop those rivets.

Those rivets are in Fastenal's "structural" rivet catalog, and are even more "serious" than the ones used on the blast cabinet. I'm convinced that patch is going nowhere.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Cool!

I used a pneumatic puller a few times!

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

Administrator

|

These days there are probably battery-powered ones. Was in a tool store recently and it was amazing what Ryobi has in those tools. Even a battery-powered grease gun.

But apparently Ridgid isn't into developing such a wide range of tools. In fact, they haven't even gotten into the 40v tools where the serious power is, like weed eaters and chain saws.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Banned User

|

Have you seen Milwaukee's 12V & 18V tools? This is JUST the 18s: https://www.milwaukeetool.com/Innovations/M18  Heat gun, 10-ton knockout, table & chop saws, magnetic drill, LED tower lights, jaws of life... |

|

Administrator

|

https://www.bing.com/videos/search?q=John+Travolta+Grease+%22electrifying%22+YouTube&view=detail&mid=74CCC86D3D70AB6FE8AE74CCC86D3D70AB6FE8AE&FORM=VIRE |

|

In reply to this post by Steve83

I drool anytime I'm in a tool store with a Milwaukee section. Multiple aisles of nothing but red.

|

|

Administrator

|

In reply to this post by Steve83

Wow! I'm locked into Ridgid, but that is an amazing range of tools.

I talked with the manager of Direct Tools in Branson about the range of Ridgid vs Ryobi vs Milwaukee. His opinion was that Ryobi has the most diverse range, but that Milwaukee is coming on strong. However, Ridgid seems to be focused on the "construction" tools, like drills, saws, impacts, etc. Ryobi has gone into the 40v tools as well, and my brother has a leaf blower and a weed eater from them. He's relegated his Stihl blower and weed eater to his cabin where he really can use the extra power of the gas engines, but he seems to be happy with the Ryobi tools for his house in town. And his wife uses the blower frequently to blow off the back porch - something she never did with the Stihl. Battery-powered tools have really turned the corner.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

| Edit this page |