Weatherproof Connectors

|

Administrator

|

I understand the pain of having to pry a crimped connection apart. Been there, done that, had the frustration.

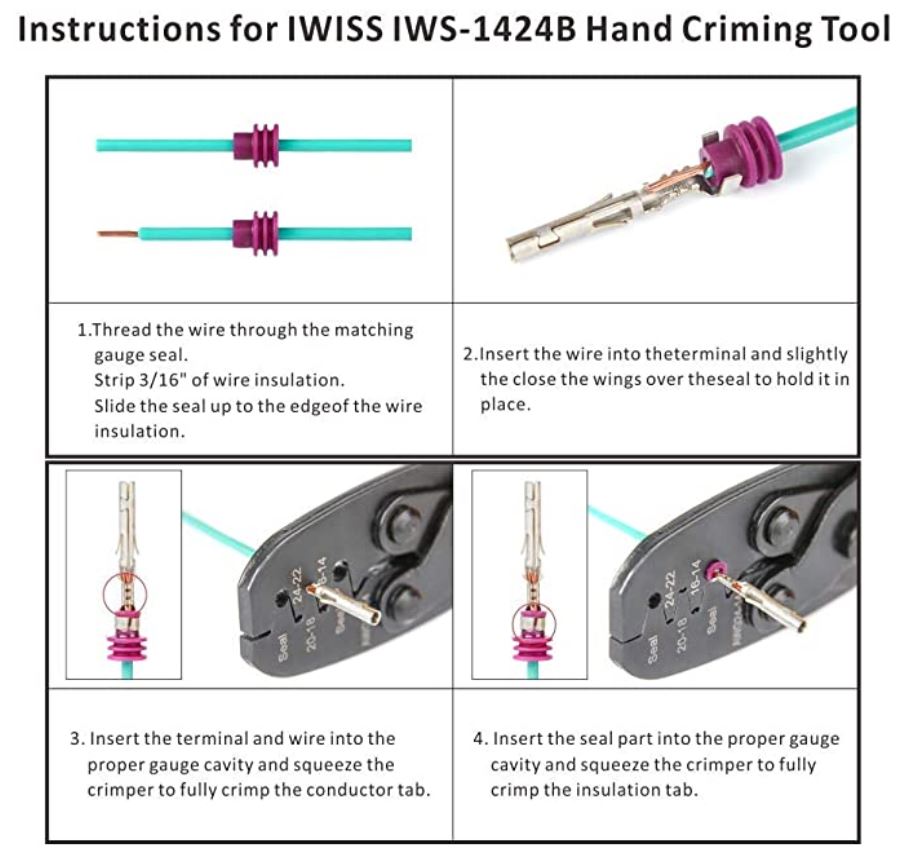

On the crimpers, one reason I was quick to order the IWISS Quick Change Ratcheting Crimper Tool Kit was because it does five types of terminals, including the exact ones that I'm dealing with. This shows the terminals it crimps, and that A58B row is exactly the terminals in the kit I have.  But when you go look at the various kits of terminals on Amazon you find ones that are more specific to the terminals in that connector kit, like this IWISS 1424B crimper, which only does two types of terminals.  But something I noticed when looking at that crimper is that they crimp the seal with the insulation. But there's no mention of that for the connector kit that I have, although the seals are exactly like the ones in this picture, so have the nose that looks like it is designed for it. Anyone do this?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

In reply to this post by Rusty_S85

This is a great thread with perfect timing for me! I'm about to do some wiring in my truck and will be fully rewiring my 69 Mustang when the time comes. For the Mustang, I have an American Autowire kit for which requires special tools. I need to look into the the type of connectors in that kit. Whatever I do, would like the tools to transfer over and be used for both projects.

Rusty, curious why you dislike the Deutsch connectors? Bunch of builders on YouTube boasting about them even saying they wouldn't use anything else.

John

"Blackie" - 1986 F150 4x4 - Mildly warmed over 351W HO - Original owner |

American Auto Wire kits use the open barrel type crimps, you can use the crimper that was posted above. These have no seals but be warned American Auto Wire supplies double width open barrel terminals when you have to crimp two wires into one terminal side by side. These are hard to do with the above crimpers as the terminal doesnt fit properly in the tool. Thats why I am going to hit the web tonight after work and try and find a dedicated crimper for the double width open barrel terminals to make life easier. You can use the crimper above but youll have to start with the largest opening and work your way down to the size your wire is to get a proper crimp.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

In reply to this post by Gary Lewis

Thats a nice crimper, only thing is I wont be crimping that many different types of terminals and I already have a crimper that does the deutch terminals and a Matco crimper I use at work for your standard crimp terminals. I need to get a dedicated one for the Metri-Pack connectors that I will be using, I could go with GM style Weatherlock connectors but I have to still buy Metri-Pack terminals as that is what Sniper uses as their terminals. Might as well keep them all the same.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

In reply to this post by Rusty_S85

I think I'd change out the connectors on the American Auto Wire harness to ones that take more common connectors and that are sealed.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

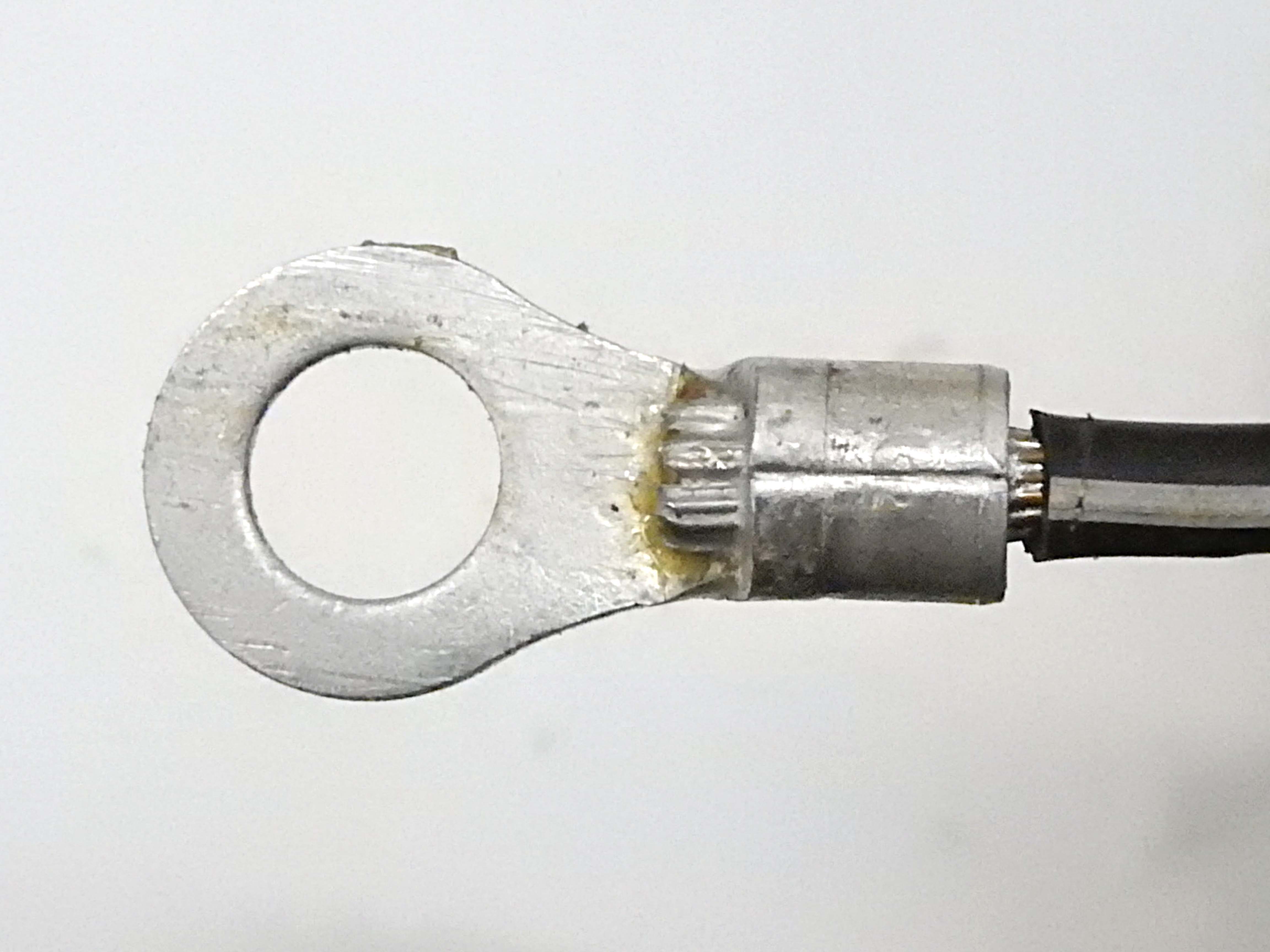

I know this doesn't exactly fit under the topic, but we have discussed soldering vs crimping so I thought I'd share here an issue I ran into today.

I was installing a ring-tongue terminal on the EFI PDB's ground and discovered that Ford's wire isn't really a standard AWG. The #12 slot on the stripper didn't cut enough of the insulation to allow me to strip it. So I measured the wire at .086-.089" and then looked at the AWG table: 10 0.1019"

|

|

Went right through! A bit surprising.

Looks nice and professional though!

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

Administrator

|

Yes, Dane, I was surprised the solder went right through. I've always read that a proper crimp is gas-tight, but I wouldn't think something gas-tight would allow solder to wick through. And I used the proper ratcheting crimper.

Maybe because the wire was too small? However, it was larger than the standard #12 wire and the terminal was made for #10-12 wire.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

"Gas tight" only refers to the interface between the connector/terminal and the wire - not anything inside the wire itself. Both mating surfaces have to experience some type of scraping action (Fast-On terminals) that cleans the interface as the connector is plugged in then maintains the seal by that spring pressure, or plastic deformation (crimps) that crushes both surfaces to eliminate air between them, and maintains it just by being a new rigid shape. But stranded can definitely wick air, moisture, or anything else (solder) through the capillary action between the internal strands. This is why I always use either waterproof connectors (Weather-packs) or adhesive lined, heat-shrink terminals.

Actually Gary thinking through what I said about solder was only half true. I do still believe (based on the literature I've read from terminal makers) that smaller pin terminals don't need it. But in larger ones I definitely do still solder/tin the ends. I tend to do it before crimping for things like screw-terminal junction boxes but it also adds air/moisture protection as well...

--

1981 F-250 Custom. 6.6L V8, 4 barrel Holley carb, ARA aftermarket A/C. |

|

Administrator

|

If air or moisture can wick along the strands then crimped-only connections really DO need to be protected. Obviously one way to do that is with a waterproof connector. But another way would be by soldering. Tinning can certainly help, but soldering would offer even more protection.

Thinking about it, if the wire was tinned and then crimped into the terminal it would be easy to heat it up and have the tinning flow to the terminal, sealing it tightly. You might not need to add any more solder.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Gary Lewis

Yep when you heat the crimped fitting and apply solder it will wick through the wires. Its why you have to be careful cause if you keep adding solder it will keep wicking into the wire and you could easily end up with the wire being full of solder many inches past the connector.

What I like doing to ensure that doesnt happen is I leave a little of the wire exposed past the crimp so you can see wire between the insulation and the crimp. Then I apply solder on the other side of the crimp and when I see solder starting to wick into the exposed wire I stop. This way if you ever have to replace the terminal down the road you can cut the wire off at the terminal and strip it back and use it. If it wicks too far then stripping becomes harder and crimping becomes harder as well.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

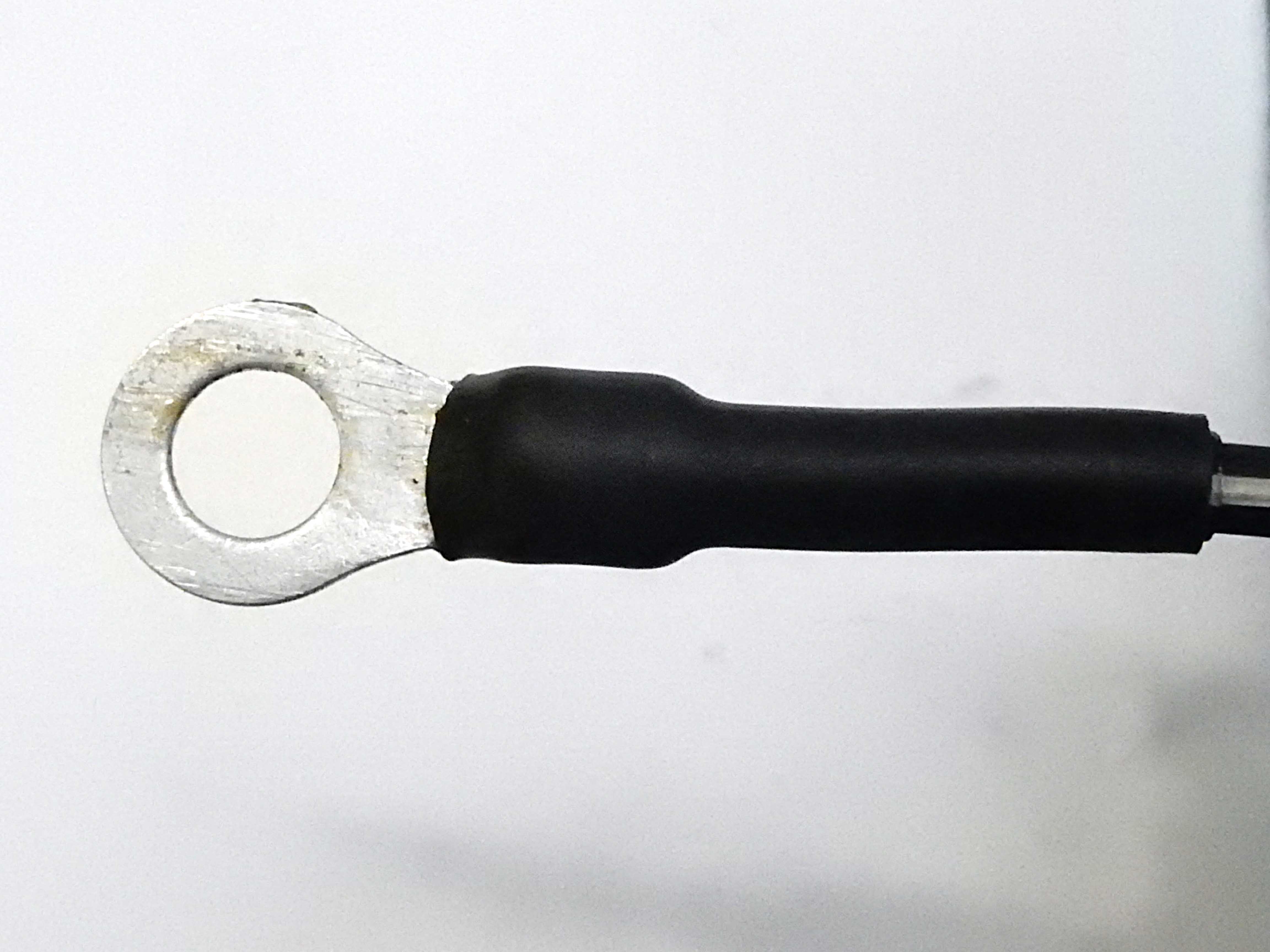

That's exactly what I did - added solder until it showed on the bare wire between the crimp and the insulation, and then stopped. So I'm confident there's no solder way back in the wire. However, I always provide support via the adhesive-lined shrink tubing anyway.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Thats good, I hate going behind my boss cause he prefers soldering everything even computer terminals when the manufacturer clearly states to just crimp with weather proof crimps then heat the built in shrink tubing to create the weather proof seal. But when I have to go behind him I end up cutting back 6 inches from the terminal he made up before I get to clean wire as he just loves pushing solder into the wires lol. Big reason why I have grown to hate soldering terminals cause I used to solder everything, even crimp fittings I would place them and solder them without crimping. Now I crimp and only solder to keep the boss from complaining about using crimps and not soldering. Only time I will solder regardless is for vial circuits such as alternator wires, battery wires, fuel pump wires, etc. But non vital circuits like turn signal indicators or dome lights I will just crimp alone as they arent as picky if the connection isnt the best.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

I started soldering in 1957. I turned 10 that year and got a crystal radio kit for my birthday. Over the years I've soldered connections in many other kits, like my KnightKit R100A ham receiver, Heathkit ham transmitter, Heathkit oscilloscope, etc, etc, etc.

In fact, I've soldered chips and transistors into many commercial computers, including DEC PDP-8's. And I built my own 8085-based microcomputer - and all of the connections were soldered. So I'm very comfortable soldering. And yes, along the way I've had a cold solder joint or two, but I've learned why that happened and make sure it doesn't happen any more. Plus, I know not to continue pushing solder into a joint as I've seen how far it can go up the wire. Given that, I tend to solder all of my connections on my trucks. And so far I've not had a failure. I do want to try crimping the terminals in the waterproof connectors, but joints in wires and to terminals like that ground will continue to be soldered - even if they are crimped.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Let me know how that works cause I am leaning towards soldering my terminals as well after crimping but I am a little apprehensive with the rubber weather seal and how it will handle the heat of a solder iron heating the terminal that is crimping it up to 800 - 900 degrees to quickly fill the terminal with solder.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Administrator

|

You don't need to heat to 800 or 900 degrees. Wikipedia says "Alloys commonly used for electrical soldering are 60/40 Sn-Pb, which melts at 188 °C (370 °F)".

My Weller soldering station has a dial calibrated in degrees F, and I usually keep it around 450-500 as that allows it to melt the solder quickly on smaller wires w/o melting the insulation. But on things like that ~#12 wire I cranked it up to 700 as that reduces the time to melt the solder, which reduces the heat transfer to the rest of the wire. As for the seal, so far I've not crimped the seal into the insulation crimp. Instead I've had it a few inches down the wire until after soldering and then slid it up against the insulation crimp. And in every case it has gone into the connector w/o sliding back. Nor was it harmed in the soldering process. But as said above, one illustration I found shows crimping the seal to the insulation, so that would have it subject to a bit of heat. However, since even the insulation doesn't melt I'm sure the seal won't either.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Well, I take that back. My dial is sitting at 600F for small wires.

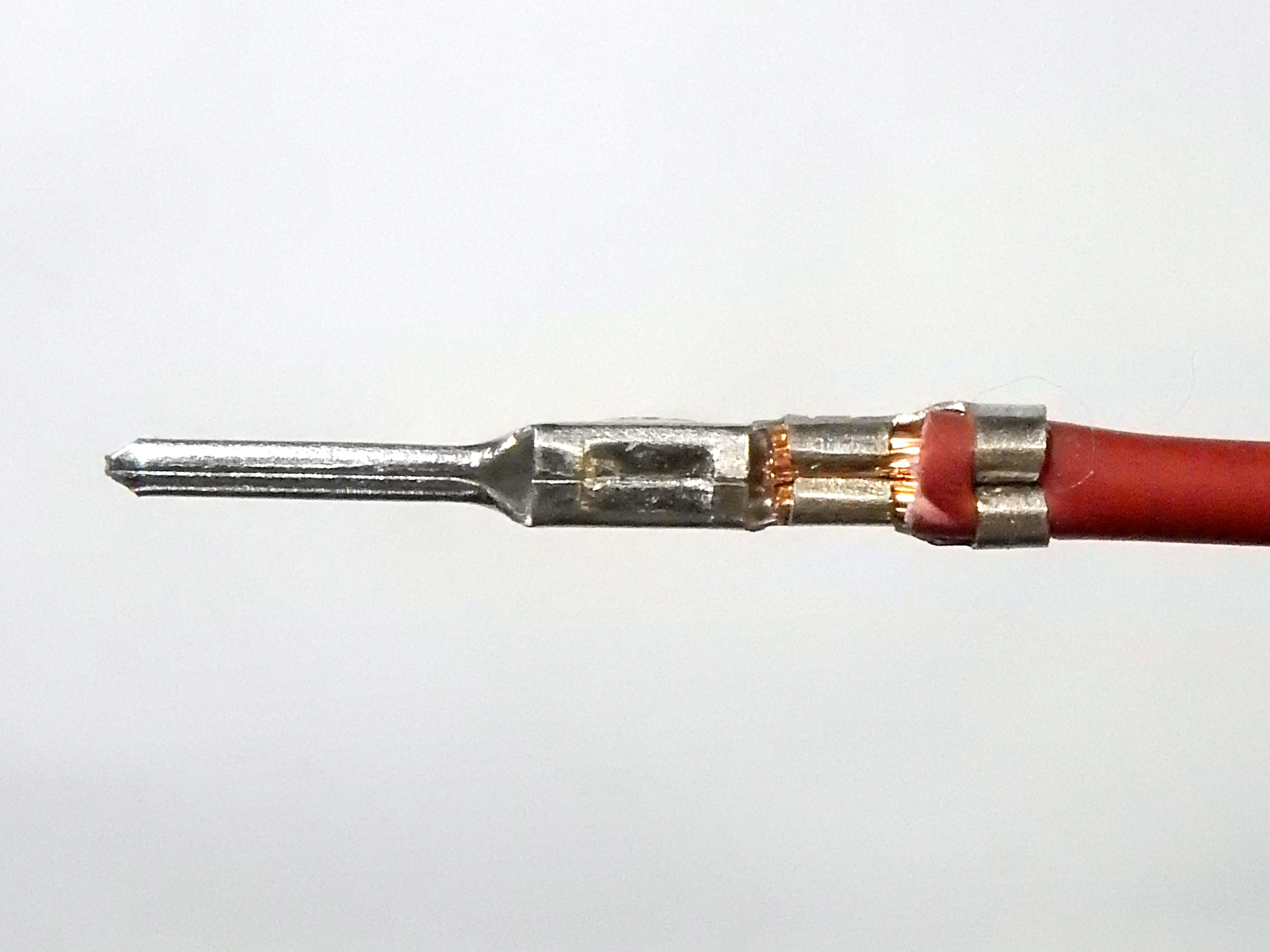

Anyway, I got the IWISS crimper in this morning so I did a trial crimp and then soldered it. Perfect! (But I did forget to tin the wire before crimping.  ) )

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Looks like a good crimp, Gary!

John

"Blackie" - 1986 F150 4x4 - Mildly warmed over 351W HO - Original owner |

|

In reply to this post by Gary Lewis

DEC PDP-8! Memory lane there. I work on the software end, but taught myself to program Fortran on a DEC VAX (PDP-11).

81 F150 Flareside, Edelbrock Pro Flow4 FI, hydraulic roller 351W, E4OD, 4x4, BW1356

92 F150 RCLB 351W E40D BW1356 mostly stock |

|

In reply to this post by Gary Lewis

Oh I know, but my soldering iron doesnt have an adjustable temp its a 900*F iron that is always 900*F when fully heated. Its why I get my solder ready and tin the iron first to improve heat transfer so I can quickly get the solder in before putting too much heat into the wire itself. If I can find a quality adjustable soldering iron I might pick one up for use at home as I also want to get an adjustable DC power center so I can bench test electrical circuits during assembly

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

| Edit this page |