The Truck of Doom: An Occasional Build Thread

Re: The Truck of Doom: An Occasional Build Thread

|

Administrator

|

I hope for the best, but I don't really blame them.

I put up with WAY too much  when it came to labor negotiations. when it came to labor negotiations.

And though I was moderate, and just wanted a contract, in retrospect I would/should have told them to go #+&"*# ¥π©%? sideways... twice! and walked, picketed, and sabotaged every thing I could lay my hands on.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: The Truck of Doom: An Occasional Build Thread

|

Administrator

|

I checked my leakdown tester.

There is no indication of orifice size. Though it may be rather small. (a 500cc four cylinder bike would have a 125cc cylinder) A 302 (5.0l) would fit 10x that size engine, or more that the total displacement in one cylinder.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: The Truck of Doom: An Occasional Build Thread

|

Administrator

|

Ok, Jim. Thanks for checking.

I've read that the "good" ones have a very smooth orifice that doesn't induce turbulence. Supposedly some of them, probably like mine, go turbulent at high flows. However, at that point I'm not worried - if there's that much flow then there is a problem and it doesn't really matter how bad the leak is. It is bad.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: The Truck of Doom: An Occasional Build Thread

|

Administrator

|

The fact that Matthew's 5 SCFM compressor can't keep up with the leak is telling enough for me.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: The Truck of Doom: An Occasional Build Thread

|

Administrator

|

I think we need to think through how to use the results of a leak-down test.

As I'm going through this myself I've been thinking about it a lot, and the conclusion I'm coming to is that if an engine is running seemingly well then I'd leave it. But, if you have it out, like I do with Big Blue's 460, then I'd seriously consider rebuilding it. Had I not already pulled the engine when I ran the test I probably would have at that point since I'm in the midst of a huge rebuild/transformation. But, were I not in this quest I'd probably have left it as it was getting pretty much bog standard carb'd 460 MPG. (IOW, poor.) I say all of that to say that the leak-down test is one tool to use in decision making on an engine. If it is running well and not using an excessive quantity of oil then poor results of the test are an indication that at some point in the future a rebuild will be needed. But if it is dropping a couple of cylinders, as Big Blue was at idle, then the test may tell you how to repair it.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by ArdWrknTrk

That presupposes that the compressor is actually producing that volume, does it not? It also assumes I know what I’m doing, a questionable assumption at best. I’m just having a hard time with the idea that I have ring problems on a truck that has had the oil changed religiously since day one, and only has 135K miles on it. Yes, it sat a while and something could have happened as a result, but surely there would be some other sign of problems? |

Re: The Truck of Doom: An Occasional Build Thread

|

Administrator

|

In reply to this post by Gary Lewis

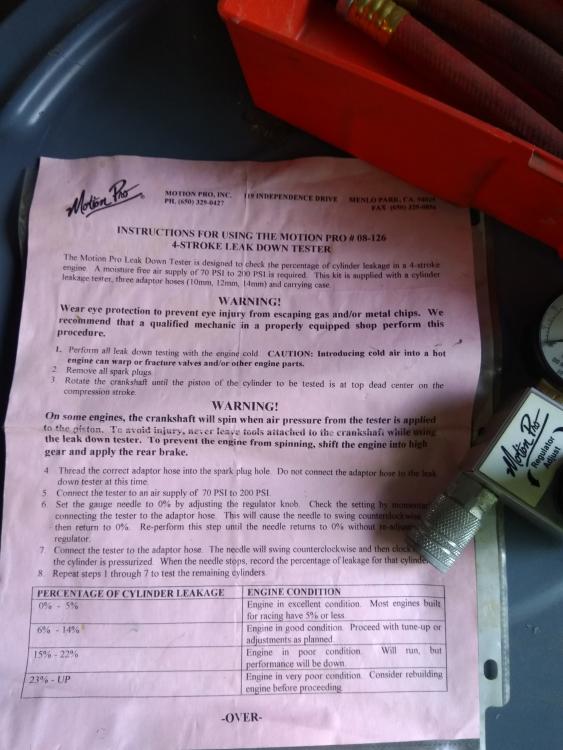

You can see the suggested protocol at the bottom of the pink page.

EVERY engine is going to need a rebuild in its future, unless the vehicle it is in is totalled.... or we discover the flux capacitor.  Matthew has discovered that his engine may have compression, but can't hold it. Does he have excessive blow by? Does he have cracked rings in that one cylinder? Is there a pit in one spot at the top of that cylinder? Is there a hole it that one piston? Pull out your crystal ball and peer deeply, oh wise one!

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: The Truck of Doom: An Occasional Build Thread

|

Administrator

|

In reply to this post by Dorsai

Matthew, you know that when the inline 6 came out engines didn't last 100k, even with the best treatment (unless it was Mercedes or something)

Maybe the rings are just stuck in their grooves and you need to treat it to some Rislone and a steady diet of high detergent diesel oil. Maybe you need to beat on it pretty much all the time to free them up. Maybe the bores are severely worn. Check with the borescope at Gary's while you're doing the leakdown.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: The Truck of Doom: An Occasional Build Thread

|

Administrator

|

Now you are going way back, but even then some of the old in-line sixes lasted, particularly Nash, and Chrysler stuff. Their old flatheads would run forever. The early OHV engines were plagued with valve problems which is why Willys and Rolls-Royce both built F-heads, overhead intake, side exhaust.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

Re: The Truck of Doom: An Occasional Build Thread

|

Administrator

|

When the Mustang came out with a generator in '64 the (other) I-6 was the only engine available.

And I was in diapers. Machined surface finishes (bores) looked like the surface of the moon compared to what we get today. Mostly because they just needed to be cranked out and people didn't drive as much as now. Customers didn't expect an engine to last. The whole crosshatching to break the rings in thing was because metallurgy was far inferior and tolerances were not good. A newly built engine was 'tight' and those bores needed to be plateaued. I can still remember building a 441 Victor that I couldn't get to seal up, or stop seizing. Rick held it wide open and tossed some BonAmi into the velocity stacks! Even today the bore needs some surface roughness to give the oil somewhere to go. But the opposite problem is true. The bores can be too smooth. That's why we recommend break-in oils instead of full synthetics for the first 500-1,000 miles.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: The Truck of Doom: An Occasional Build Thread

|

Administrator

|

Jim, with the newer chrome rings, the bores need to be nearly smooth.

You will enjoy these, first, a Craftsman 10 HP cast iron engine (built by Tecumseh when they made very good engines) It is on a 1972 Sears Custom 10XL I purchased from a fellow in Salisbury MD. He was going to use it as a pulling tractor as it has the almost indestructible AYP 3 speed with hi-lo transaxle. Engine would blow oil out at higher rpm. I bought a set of rings for it along with the gaskets and seals, roughed the virtually straight bore (no ridge) with some 120 emery paper, reassembled it, getting the correct end clearance on the roller bearing crank. Once I ran it in, no more oil blowing out and it runs great. The second one is a Briggs & Stratton opposed flat head twin, had enough blow by it wouldn't idle with the breather hoses connected to the air cleaner. It's on another Sears product, a 1983 GTV16, which is an actual garden tractor. I was given it by a co-worker who had originally bought it to use at his retirement home in Charlotte County VA. When he couldn't find a mower deck for it. It was given to myself and another Ford truck owner, who when he was diagnosed with colon cancer at 40 told me to just take it and do what ever I wanted. Same thing, except that one really needed boring, new rings and gasket set, lapped the valves, sanded the bores enough the seat the rings, put it together, actually found a new drive pulley adapter from Sears parts! Engine is a horizontal shaft that sits backwards in the tractor and has a drive belt system that would make a Corvair look simple. Former manager gave me a sleeve hitch for it after he found out the difference in an ST vs GT frame (mine is 4" wider). Runs great, the varidrive takes a bit to figure out, but once set up with the correct belts, is neat. I found a 44" deck for it and one neighbor and I use it for rough clearing.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

Re: The Truck of Doom: An Occasional Build Thread

|

Administrator

|

Bill,

I understand about chromemoly rings. The Briggs, how many horsepower is it rated? I sure could use a compact brush hog.  Variable pulley belt drive is a hoot. There are so many permutations. Why do you compare this to a Corvair? I mean I've seen the accessory belts on that engine, but they have a transaxle.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Re: The Truck of Doom: An Occasional Build Thread

|

Administrator

|

Briggs is 16 HP, belt comes off the horizontal shaft, engine is mounted with the crank longitudinal and the traction drive pulley is on the back, which is the flywheel end. Transaxle input pulley is on the right side and the shaft for it is transverse. Belt comes off the engine goes trough a pair of pulleys on the right side of the frame at an angle. Outboard pulley is a V groove, the inboard is flat. Engine turns clockwise viewed from the back, drive side of the belt (1/2 x 67) rides on the flat idler, then goes somewhat upward to the top side of the variator (two groove V pulley with the center sliding) the bottom side of the variator, the belt goes straight forward to the outboard (V) idler and up the the drive pulley. The rear belt from the variator to the transaxle has a single V idler and is a 5/8 X 40 belt. Clutch works by moving the variator on it's lever forward far enough that the primary belt is no longer in contact with the drive pulley on the engine.

Here's a link to a YouTube video on it: https://www.youtube.com/watch?v=uWBTJvY7jLg&t=72s

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

Re: The Truck of Doom: An Occasional Build Thread

|

Administrator

|

In reply to this post by ArdWrknTrk

Part #121G @ O'Reilly's https://www.oreillyauto.com/flux-capacitor |

|

While I'm waiting for a usable valve spring compressor to arrive, I thought I'd take a closer look at the parts I pulled from cylinder #1. Of course, I have questions.

My trusty Haynes manual says to "check rocker arms and fulcrums for signs of wear." I think my parts look pretty good, but it would have been nice had they described what constitutes 'signs of wear', and how much is too much. For example:  If you look on the top and bottom edges of the oblong hole in the center, you can see small crescents, which I assume are wear marks from the fulcrum. It doesn't look (or feel) problematic to me, but what do I know? Same with the bottom:  I have shiny wear spots, as I would expect. The dark spot in the center of the pushrod socket looks like the original cast surface that the pushrod ball doesn't reach to. The pushrod itself is nice and straight, and the ends are shiny and smooth. Is there any reason not to throw these back on when the time comes? |

Re: The Truck of Doom: An Occasional Build Thread

|

Administrator

|

They look good to me, but let's see what other have to say.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: The Truck of Doom: An Occasional Build Thread

|

Administrator

|

In reply to this post by Dorsai

They look pretty good for close to 40 years of use. Run your fingernail across the tip where the valve stem rides. If you feel a pronounced ridge, that would be the only real concern, but if you put them back where they came from it shouldn't be an issue. Fulcrum area looks great, no signs of scoring.

After reassembly, before starting it, pour a small amount of oil into each rocker arm so they aren't dry.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

Re: The Truck of Doom: An Occasional Build Thread

|

Administrator

|

I agree. From my end of the internet it all looks good to me.

Personally, I would probably slather every thing in STP as an assembly lube. I use Permatex Ultra Slick 81950 for cams and new engines, but if you're just going back with parts that are already 'married' STP is fine.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

In reply to this post by Gary Lewis

The Council of Elders has spoken!  Back on they will go. Back on they will go.

|

Re: The Truck of Doom: An Occasional Build Thread

|

Administrator

|

I had a good chuckle!

STP is cheap insurance that all these fulcrums and pressure points are well lubed on startup.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

| Edit this page |