Definitive way to wire an electric fuel pump for a Pre EFI Bullnose

Definitive way to wire an electric fuel pump for a Pre EFI Bullnose

|

I’ve spent the last 4-5 days/ nights reading every possible method and thought on the subject. I ultimately pulled the trigger on purchasing the Carter A68301 oil pressure switch, a Hella 5 pole relay and pulled an inertia switch from a ‘95 F150 at the local yard.

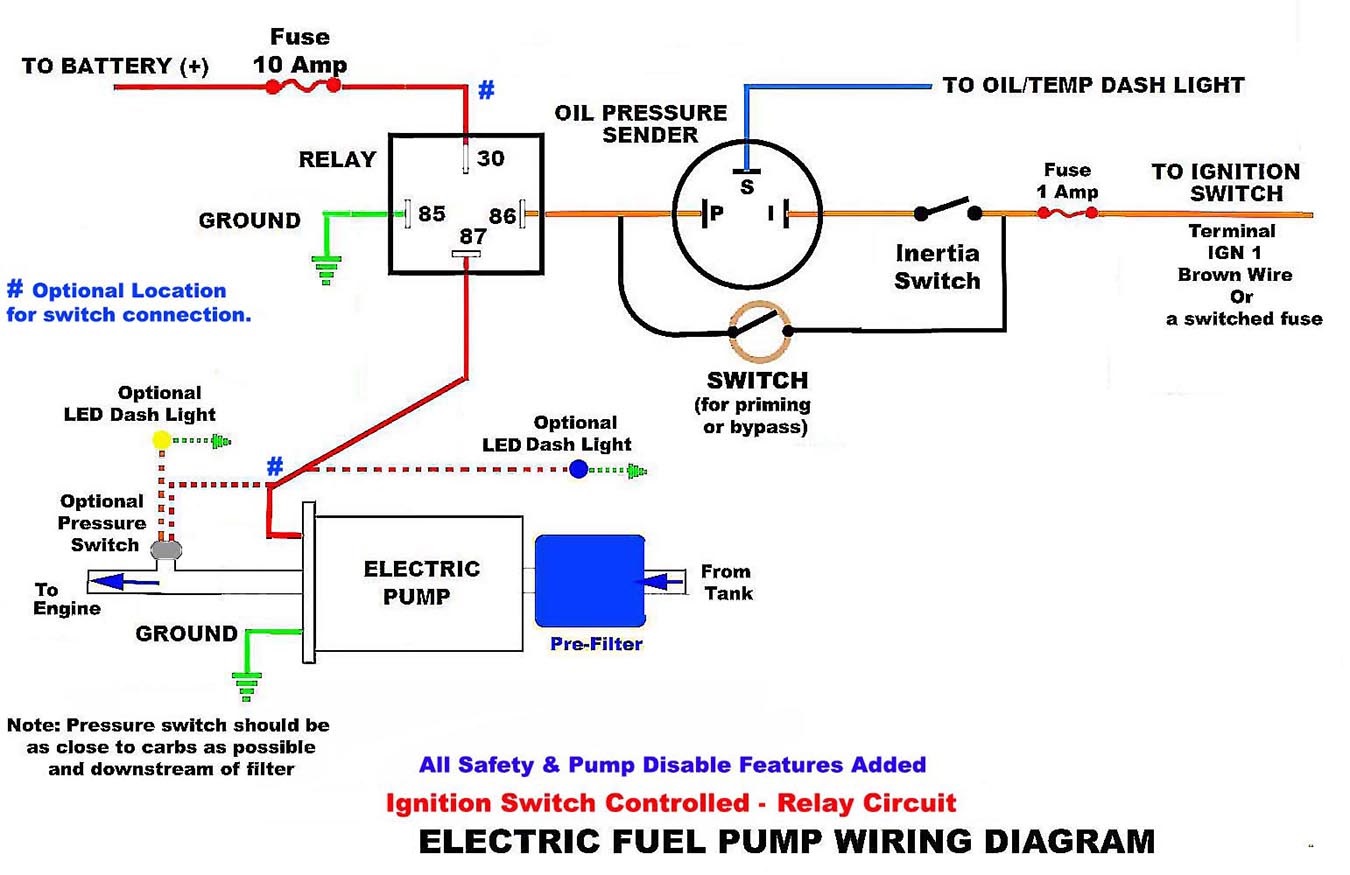

I’m very confident in these selections, so if we can, I’d like to not get into the whole “better options” discussions. Where I’m looking for advice from the people I I trust, is in the “definitive” way to run the wires. Let’s start with what I’m attaching to; ‘85 F150 4.9L converted to duraspark many years ago. I’ve installed a 33 gal Bronco tank in the rear and have a Bosch 6700 FDM that will supply fuel to either my existing YFA or, in the near future, a Sniper TBI unit. I’m good on the fluid side of things but would like to hear opinions on the electric side. And if you do respond with your suggested way of wiring, PLEASE tell me WHY you like your way AND what it is about the other suggestions that you don’t like. I’ve kinda zeroed in on this schematic and will probably be following it to the T. However there are a number of variations that could be made.  First is where to place the inertia switch. Some folks want it before the relay and others say to place it after. Even Ford changed their mind at some point around ‘91-‘92 and this is probably my biggest hang up. The inertia switch that I pulled from a ‘95 has what I’m guessing are 14ga wires coming from it. While everything I read about the wires to the pump suggest 12-10ga wires. Seams like a problem to me. However the EVTM for an ‘85 shows the switch just before the pump. The other area that has me conflicted is the suggestions of the inertia switch affecting ground as opposed to power. I’m clueless on this one. Another place I’ve read something about having the inertia switch control the 87a tab on the relay. I completely don’t understand what they’re trying to do there. There are probably a couple of other ideas out there, but you get why I’m asking for advice. Thanks in advance and Cheers!

Kurt K

'85 XLT Lariat, 4.9L, NP435, 3.08LS, DSII, 130a 3G, PMGR, '87 MC, P235/R75 |

Re: Definitive way to wire an electric fuel pump for a Pre EFI Bullnose

|

We sidestepped all that thought process because our Bullies are diesel. Less fire risk. We just wire the pump to the ignition On position.

I admire your thoroughness. We have one gasser Bully but it's a stock block pump.

Reno in Central Texas, 86 F250 XLT Lariat eclb 2wd 6.9, plus 2 Bricknoses, 1 Aeronose that's getting a Bullnose front clip, and parts trucks. Busy lads, father and sons wrenchers.

|

Re: Definitive way to wire an electric fuel pump for a Pre EFI Bullnose

|

Administrator

|

In reply to this post by Tarheel Blue

For reference I've included the schematic from the '85 EVTM, below. And I would wire it exactly the way it shows, which is essentially the way you've diagramed, with one exception - your priming switch. Your diagram indicates you plan to use a toggle switch, and I would NOT do that. Instead I'd use a push button. A toggle could be accidentally switched on to bypass the inertia switch in an accident, which could be a major problem. A push button switch probably wouldn't.

Also, tell me more about the FDM. Is this an EFI FDM from the later trucks? If so I need to tell you about the issue I had when doing the same thing - way too much fuel pressure. I put a return-style regulator in the engine compartment and fired it up, only to find the pressure gauge oscillating, and spiking too high. I had to put a dead-head style regulator after the other one to get steady fuel pressure at the proper level. You can read about it, and see my video, here.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Definitive way to wire an electric fuel pump for a Pre EFI Bullnose

|

I completely agree that the switch should be momentary, just not sure if I’ll need it or not. In theory, the three pole oil pressure switch should provide a prime function, but we’ll see how it works.

The Bosch 6700 FDM is a stock replacement for the Bronco tank. It is running through a Holley 12-880 by-pass regulator that can be adjusted as low as 2 psi, so the 4-6 psi for the YFA should be no problem. I have been cautioned to be alert for possible pulsations but there are modulators that easily handle that if needed.

Kurt K

'85 XLT Lariat, 4.9L, NP435, 3.08LS, DSII, 130a 3G, PMGR, '87 MC, P235/R75 |

Re: Definitive way to wire an electric fuel pump for a Pre EFI Bullnose

|

Administrator

|

I don't see how the oil pressure switch can provide a prime function. With no pressure P & S will be connected and the light will be on. With pressure P & I will be connected and the pump will run.

I think you might like the push button for priming. As for the regulator, that's the one I am using and I had the pulsing problems. I didn't know about modulators, but the 2nd regulator was on hand, so I used it.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

As for priming what dose it on our year EFI trucks?

I thought it was getting a signal from the computer when the key was turned on and that cant happen with you (yet?). Why not pick up the power when cranking at the solenoid / relay on the fender? It would be getting power as soon and you started turning the motor over where the PSI switch would not send power to it till the oil PSI came up to close the switch. Now I said yet? do we know how the after market EFI system deals with this? Dose it's computer do this like the factory one does? Have you looked into how that system gets wired and maybe you can use most of it with a jumper or 2 to work with the carb till then? Then pull the jumpers and wire it like the EFI system wants? Sorry if I am throwing a wrench into the gears  Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

Re: Definitive way to wire an electric fuel pump for a Pre EFI Bullnose

|

Administrator

|

Only the EFI trucks prime. The rest of us just crank until we have gas as the e-pump gets full power in Start.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Definitive way to wire an electric fuel pump for a Pre EFI Bullnose

|

You have both hit on one of the biggest hurdles that I’m trying to understand (there will be more questions later about other areas), and again, I’ve been reading for days and can’t seem to figure out the best way to go about getting a short ( 3-4 second) prime activity prior the the starter actually engaging. I want the bowl of the YFA full of fuel prior to the engagement of the starter.

In my thinking, the simple action of turning the key to run, pausing a second or two and then turning the key further to start. If I’ve wired it correctly, there would be power to the pump in run ( Duh!, the pump has to have power any time the key is at RUN ) and of course in start. What am I missing?

Kurt K

'85 XLT Lariat, 4.9L, NP435, 3.08LS, DSII, 130a 3G, PMGR, '87 MC, P235/R75 |

Re: Definitive way to wire an electric fuel pump for a Pre EFI Bullnose

|

Administrator

|

The oil pressure switch will only close the contacts when the engine is running. So just turning the key to Run won't prime the carb.

And you do NOT want to bypass that permanently. When I got Big Blue the sump was FULL of gas because someone bypassed it and the PO left the key in Run. I drained 6 quarts of oil and 7 quarts of gas out. If you want to prime it put a pushbutton switch in to temporally bypass the oil pressure switch. Turn the key to Run, push the button, let up, and crank.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Definitive way to wire an electric fuel pump for a Pre EFI Bullnose

|

In reply to this post by Tarheel Blue

I think most EFI systems have some type of check valve that holds pressure in the system in between engine runs, so priming is not really a concern. I don't really have part numbers to refer to or anything, but I think that's supposed to be how it works. Most of my experience with EFI is with foreign stuff though, maybe the domestic manufacturers don't do that.

81 F150 Flareside, Edelbrock Pro Flow4 FI, hydraulic roller 351W, E4OD, 4x4, BW1356

92 F150 RCLB 351W E40D BW1356 mostly stock |

Re: Definitive way to wire an electric fuel pump for a Pre EFI Bullnose

|

In reply to this post by Gary Lewis

Totally agree with Gary on the “why not to” and therefore the push button solution. Except I’m trying to avoid the button. Seems less user friendly, as in, other people not knowing the the secret sequence to simply go for a spin.

Something that I’ve been trying to work through in my head but don’t know enough about. I’m hoping Gary might?  Using a 4 pin relay, have the “low” 12v when key in RUN to trigger pin 87 sending the “high” 12v current on to the fuel pump. Then after a couple of seconds, driver would push in the clutch and turn the key to START which simultaneously sends “low” 12v current through the Oil Pressure Switches I pole and then on to a 4 pin relay which sends “high” 12v current on to the pump AND grounds the “low” 12v signal to the first relay, resetting it to “normally open”. The idea of the check valve is very intriguing, I’ll look into that, thanks!

Kurt K

'85 XLT Lariat, 4.9L, NP435, 3.08LS, DSII, 130a 3G, PMGR, '87 MC, P235/R75 |

Re: Definitive way to wire an electric fuel pump for a Pre EFI Bullnose

|

Administrator

|

The push button would be rarely needed. Very rarely. In fact, there probably aren't more then a few hundred carb'd vehicle in the world that have such a setup, and they have all been added by someone like us.

Why? Because after a carb'd vehicle sits for a long period of time the bowl will be dry from evaporation. This is more of a problem now than it used to be since our gas is more volatile given the ethanol that is in most of it. But if you have driven the vehicle in the last few days there should still be gas in the carb and it'll start right up. So priming is only helpful, not needed, when the vehicle has set for a long period of time. As for the relay bit, I'm not following what you are suggesting. But, I do see a way of automatically priming things. A timer circuit could be set to pull the fuel pump relay in for X seconds each time the key is turned on. But leaving the key on would not keep the relay on. So you would unknowingly be priming the carb briefly each time you turn the key on. But normally you go right through Run to Start and there's only a few milliseconds of priming, which probably wouldn't do anything. But if the truck has set for some time you could turn the key to Run, wait a couple of seconds for it to prime, and then crank it.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Definitive way to wire an electric fuel pump for a Pre EFI Bullnose

|

The idea of a timer sounded great so I spent some time w/ google and finally settled in on these two options.

This one, we'll call OPTION A https://www.revolutionelectronics.com/Products/Fuel_Pump.html is more or less "plug and play" And this one, OPTION B https://www.amazon.com/5V-36V-Module-Trigger-Switch-Display/dp/B07H7L9W3T/ref=sr_1_1_sspa?crid=14EF5CWUFCO0I&keywords=dc+5v-36v+timer+module&qid=1638827262&sprefix=DC+5V-36V+Timer%2Caps%2C226&sr=8-1-spons&psc=1&smid=A28ZWXW3ZSVNZU&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUFMQUNTMTFJOFU5U0omZW5jcnlwdGVkSWQ9QTEwMjY2MzQzVUxGV01UR1BaNldZJmVuY3J5cHRlZEFkSWQ9QTA0Nzg4MDMxTjU1MkozRFVJWTBXJndpZGdldE5hbWU9c3BfYXRmJmFjdGlvbj1jbGlja1JlZGlyZWN0JmRvTm90TG9nQ2xpY2s9dHJ1ZQ== will take a bit more of my time and brain power. My thoughts on OPTION A is that while most of the work has been done already, it gets three demerit points. Price, the 3 second delay (not sure if 3 seconds is long enough, probably is if that's the way they designed it) and lastly is that it "reads" from the tach and I'm prone to think that I prefer my original plan of using the oil pressure switch to cut power to the fuel pump. OPTION B Has one pro and one con. The pro is that I can decide how low I would like the prime to be. The only con that comes to mind is the need to find somewhere behind the dash to mount it. As always, I'm all ears to what anyone has to say about either option or any new options. Cheers

Kurt K

'85 XLT Lariat, 4.9L, NP435, 3.08LS, DSII, 130a 3G, PMGR, '87 MC, P235/R75 |

Re: Definitive way to wire an electric fuel pump for a Pre EFI Bullnose

|

Administrator

|

I like option A. You'd be using it for exactly what it was made for. I think 3 seconds is adequate. And it replaces everything in your circuitry.

Also, it isn't clear to me that Option B is a one-shot. In other words, I'm not sure that it wouldn't give you a high output for as long as the trigger is high. You can overcome that by using an RC circuit to filter the input, but you have to add it on. And you still need the oil pressure switch.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by Tarheel Blue

Kurt,

I have not looked over either of the links but what you posted the "B" sounds like the way to go. Now for the other  On a diesel how is the glow plugs set up to run XX amount of time? I never looked into that when I had my diesel only if the plugs were getting power. Not that it helps you but the diesel used a temp sensor so the glow plugs would not turn on when warm / hot. So anyone know how the glow plug timer works? As Gary said being you are starting with a carb. the only time you would need to prime / fill the bowl is if it sat for a bit, I find about 1 week in the summer / hot out that you may need to prime / fill the bowl. What EFI system are you looking at and how do they "prime" the fuel system? Any way to find that out? Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

Re: Definitive way to wire an electric fuel pump for a Pre EFI Bullnose

|

To Gary,

OPTION B has many programming parameters, one of which would allow me to select between 1-999 sec as how long the the high stays on after the trigger. It also resets immediately after that time to looking for the next trigger. Dave, The future system will most likely be the Sniper. It has its own program that primes ahead of firing.

Kurt K

'85 XLT Lariat, 4.9L, NP435, 3.08LS, DSII, 130a 3G, PMGR, '87 MC, P235/R75 |

Re: Definitive way to wire an electric fuel pump for a Pre EFI Bullnose

|

Administrator

|

If it "resets immediately after that time to looking for the next trigger" then you will have to have the RC filter on the front end. Otherwise the timer will go again, and if the key was left on but the engine was off you'd have the pump running continuously.

A resistor/capacitor circuit will cause the circuit to trigger on the rising edge of the key-on signal, but will then drop back down so the timer doesn't go again.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Definitive way to wire an electric fuel pump for a Pre EFI Bullnose

|

I'm pick'n up what your lay'n down.

Therefore, would selecting mode P2 accomplish the same as adding the RC? Operating Mode: P1: trigger signal, the relay is on "OP" time, and then disconnect; in the "OP" time, as follows: P1.1: signal is triggered again, invalid P1.2: signal is triggered again, the clocking is reset P1.3: Signal is trigger again reset, relay off, and stop the clocking; P-2: trigger signal, the relay off "CL" of time, the relay on "OP" time, and then disconnect relay after clocking; P3.1: trigger signal, the relay is turned on after the "OP" time, the relay off "CL" time, then the operation cycles; if trigger signal again during the cycle, the relay off, stop clocking; the number of cycles times ( "LOP ") can be set. P3.2: without triggering signal after power on, the relay is on "OP" time, the relay off "CL" time, then the operation cycles; the number of cycles times ( "LOP ") can be set. P-4: signal holding function. If there is trigger signal, clocking is reset, the relay remains on; when the signal disappears, after clocking "OP" time, the relay is off; if another signal is triggered during clocking, clocking will be reset.

Kurt K

'85 XLT Lariat, 4.9L, NP435, 3.08LS, DSII, 130a 3G, PMGR, '87 MC, P235/R75 |

Re: Definitive way to wire an electric fuel pump for a Pre EFI Bullnose

|

Administrator

|

Yes.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Definitive way to wire an electric fuel pump for a Pre EFI Bullnose

|

Cool

One other thought that I had regarding OPTION B is that in keeping the oil pressure switch for not only pump cut off when the engine stops, would it not be a safety feature for the engine in an instance where, say, a hole is poked in the pan and oil is on the ground. It would shut off the pump then shutting down the engine via fuel starvation. Or would that be too late to avoid catastrophic damage to bearings, etc.?

Kurt K

'85 XLT Lariat, 4.9L, NP435, 3.08LS, DSII, 130a 3G, PMGR, '87 MC, P235/R75 |

| Edit this page |