1984 Bronco build thread

|

|

Classic |

|

List |

|

Threaded |

|

Administrator

|

Ahhh! Makes sense.

Where are you placing them?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Gary,

my plan is to make a small panel face for them and mount it under the dash just below the "wallet pocket" (or maybe its for cigarettes?? Ive never really known) just to the right of the steering wheel. my bronco had a heated rear glass control box in that location so there is some bracketry I can use for mounting. my rear glass is apparently not original because I have a standard non-heat window and in Ga that isnt really a very important feature anyhow. I mocked up the panel with cardboard to make sure Id be able to see the gauges well and that it wouldnt be in the way of anything like the transfer case shifter. I contemplated putting the gauges inside the "wallet pocket" in the dash but decided Id rather reserve that for recessed mounting space for switches at a later date. I like what you did with Big Blues extra gages and switches by the way, I just dont want to put holes in my new "radio delete" bezel courtesy of Rembrant. you know, while Im thinking about it.. does anyone have experience making heat shields? My exhaust manifold melted the pigtail on the back of my alternator. nothing else seemed to be damaged and I already rebuilt the pigtail/harness but Im sure it will happen again and the heat cant be good for the alternator. Id like to make a heat shield for that spot but dont have any experience. would a simple piece of bent thin gauge steel work well, is there a good commercial solution (as far as the material goes), or do most people MacGyver something together with a mix of insulating materials and thing gauge metal? Thanks!

1984 Bronco, mild built 300-6, Np435, 3.55 gears, 8.8 rear with Eaton TrueTrac, D44 TTB front, 31" tires, Duraspark II, Offy C, EFI manifolds, Holley 390, No AC, 3G alternator, front receiver

|

|

Administrator

|

The switches on Big Blue are set into a radio bezel from a medium-duty truck, like an F600. They used the same interior as the Bullnose trucks for many years, and they had a spot for switches above the radio.

As for the pocket right of the steering column, you can actually put gauges in there. I made a piece out of plastic to take two gauges, and you can see how I did it on the page at About Me/Projects/Gauge Pocket. On heat shields, you don't really have to have insulation if you put a piece of metal between the heat source and the part you want to protect. I made the one shown below for the OX actuator for Big Blue's front axle out of stainless, but you could make it out of aluminum and it would be very effective.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Gary, there is a lot of really clean work on your truck. Felt like that needed to he said.

My current plan is to put the gages underneath, then make a panel to go into the pocket and carry either 6 or 8 rocker switches that will control a bank of 6 or 8 relays. Then, the relays can be used for.. well.. anything. I think that bank of relays will end up living in the factory location for the digital clock (where you mounted your switches). There is a surprising amount of realestate back there. Then, when I add things as time goes on it should be easy to expand into powering them through rocker switch controlled relays. I like the idea of the switches living recessed into that pocket because it should make it hard for them to be accidentally engaged which could be problematic while driving (think throttle kicker for winching, elocker in front diff, etc). Thanks for the recommendation on the heat shield! I actually already have some thing gage aluminum sitting around so thats ideal.

1984 Bronco, mild built 300-6, Np435, 3.55 gears, 8.8 rear with Eaton TrueTrac, D44 TTB front, 31" tires, Duraspark II, Offy C, EFI manifolds, Holley 390, No AC, 3G alternator, front receiver

|

|

Administrator

|

Thanks!

On the rockers, I think you can get 4 of the Carling switches like I used in the pocket. It would be tight but I think they'd fit. If you are interested in them I recommend Over The River And Through The Woods. Those guys know their stuff and can give you essentially anything you want. And you are right, there is a lot of real estate behind where the clock goes. However, you'll have to bring all of that power into the cab and then back out to whatever you are powering. You might consider using a relay/power distribution box under the hood. Then all you have to do is take the wires from the switches out to the relays, and those wires are lots smaller.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Gary,

And exceedingly valid point. All of this is just in the "doodles on a napkin phase" planning wise and subject to change but I plan to do a fairly extensive electrical upgrade sometime soon (after I get what is already taken apart put back together). My rough plan is to set up the electrical infrastructure Ill need to be able to do basically anything Ill ever want to do all in one swoop since it will be easier to do a thorough job once. Id like to utilize the space behind the radio bezel becasue there is lots of it, its central, its reasonably mechanically and electrically isolated from engine/chassis stuff, and access is relatively easy by taking off the bezel. This would include the space originally intended for a radio. I want to make provisions for rocker switch operated equipment (as discussed above), a sound system, possible efi down the road, and who knows what else. Whenever that project comes around there is a relatively good chance that Ill pull power off the battery post and into the cab to facilitate all of this. For now I dont want to tear the whole thing down electrically, its already in a million peices mechanically. I just want startup to go smoothly for the sake of break in on the cam and rest of the engine when that day comes. For now, Im only entertaining projects that have a low/zero chance of impacting that goal. On that note.. Im considering buying a new tailgate and painting it. Then I could install my new rear glass seals. Or, the front hubs havent been rebuilt yet.

1984 Bronco, mild built 300-6, Np435, 3.55 gears, 8.8 rear with Eaton TrueTrac, D44 TTB front, 31" tires, Duraspark II, Offy C, EFI manifolds, Holley 390, No AC, 3G alternator, front receiver

|

|

Administrator

|

It is good to plan ahead. Then you get to change your mind over time and when the time comes to do it you've thought it out. I usually regret shooting from the hip.

As for the 'gate and hubs, those are just more layers of the onion to peel. And cry. And peel. And cry. But pretty soon you have enough for a Bloomin' Onion.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Hi Guys!

still moving along slowly. Its my blocks turn at the machine shop but part availability issues are eating us alive. at this point, Id settle for a guarantee that Id have the engine back by March. I dont think Lloyds of London writes policies like that though.. Im kicking around buying everything to rebuild my front hubs while I wait. I may do that when some cash frees up after Christmas. It also occurred to me that I could find a junk yard front "3rd member" (if you can call it that), clean it up, check the basics (backlash, preloads etc) and pack it with grease for a rainy day. or maybe rebuild it down to road. and ofcourse there are other little things here and there. I drained all of the gas out of the bronco in August sometime and burned it in other vehicles so it wouldn't go bad. I thought Id be starting the engine up sometime in October or November at that time so I left it empty. It just occurred to me that I may need to put something in the tank to prevent it from rotting out over the next few months. A new fuel tank is in the cards but hopefully not right now.. thoughts? maybe a few gallons of stabilized or zero ethanol 93? I hope everyone is doing great! -John

1984 Bronco, mild built 300-6, Np435, 3.55 gears, 8.8 rear with Eaton TrueTrac, D44 TTB front, 31" tires, Duraspark II, Offy C, EFI manifolds, Holley 390, No AC, 3G alternator, front receiver

|

|

Administrator

|

Sounds like you are going to have some time to attend to other things. The front hubs might be a good place to start.

As for the gas tank, if it isn't dry I'd consider Stabil. Wouldn't take much.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Hi guys! The new gage face is mocked in. I should have it permanently mounted tomorrow, then I can start working on the AFR meter power supply, and perhaps the head unit wiring. Both will probably run off of key in run position operated relays, but they will likely both draw power from the battery post through seperate wires as the head is a large variable load and the AFR documentation says only a battery lug will do for power. The other brackets are nearly finished as well. Then need fit up/trimming and the throttle bracket is getting welded in braces. The original throttle bracket flexed considerably causing strange pedal feel. Engine progress is coming along slowly. Maybe Ill have it back my late Feb. I hope everyone is doing well.

1984 Bronco, mild built 300-6, Np435, 3.55 gears, 8.8 rear with Eaton TrueTrac, D44 TTB front, 31" tires, Duraspark II, Offy C, EFI manifolds, Holley 390, No AC, 3G alternator, front receiver

|

|

Administrator

|

Hey, that looks good! But, I have to squint to tell 'cause the pic is so small, so in future could you make it bigger? How to do that should be in the Bullnose Forum/Forum FAQ's page.

Interesting that you are told the AFR meter has to have its own power. What brand do you have? Neither of mine have had their own power and seem to work fine, but maybe I'm missing something? You will, of course, fuse that power?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Gary,

Sorry, late night cell phone post. Once I have it permanently mounted with gauges in place Ill post better photos. yes, power will be fused for sure. Im contemplating if I should dive all the way into my little electrical project or just use inline fuses and convenient mounting locations for the relays to get this all put together and running again. I did remove the factory ECM last night revealing a great little chunk of space for things like that.. The AFR is from innovative. Innovate Motorsports 3918. Here is the warning from the tech sheet " Circuits that share power with the vehicle’s stereo, ignition system, ECU, lighting, or fuel pump should not be used. When in doubt, create an additional circuit using an automotive relay available at any automotive parts supplier". I conferred with a friend who is much more EE savy than I am, and his suggestion is that this thing likely needs a fairly clean and steady power feed without a lot of voltage fluctuation from something like the headlights or a big stereo head. His suggestion was to run a fused line back to the battery post. its hard for my Mechanical brain to believe that running a large wire like a size 10 from the battery to the cab and then powering the radio and the gauge (for instance) off of that wire would cause trouble, but I have little to lose by listening to someone more qualified than I am. For the record, he also suggested that it would probably work fine if I just powered everything off one wire. one of my plans for my electrical project is to have a couple of 12v+ nodes in the cab operated by either key on or key in run power relays. I would Like to have a "clean" 12v+ for things like fuel injection ECMs and AFR gauges and a "less clean" 12v+ node to drop things like the radio on.

1984 Bronco, mild built 300-6, Np435, 3.55 gears, 8.8 rear with Eaton TrueTrac, D44 TTB front, 31" tires, Duraspark II, Offy C, EFI manifolds, Holley 390, No AC, 3G alternator, front receiver

|

|

Administrator

|

No prob on the pic.

On the AFR meter, I have an Innovate and apparently missed that statement in the documentation. Don't remember what mine is fused with, but it gets power from the fuse box along with other things, and it works fine. I think most things designed for automotive use have pretty decent filtering on the power input. Otherwise they'd never work correctly due to the fluctuations the power makes as things are switched on or off.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Hi Guys! completed mechanical install of the gauge panel. Its good to make small progress after so long. The new mechanical choke bracket is also done and the new throttle bracket needs some mig welds before paint. no wiring work has been completed on the AFR, and I may wait until I charge the battery for cranking the new engine up to do that so its easier to validate as I go. It hasnt been my most productive day, but its been the most productive day in a long time.

1984 Bronco, mild built 300-6, Np435, 3.55 gears, 8.8 rear with Eaton TrueTrac, D44 TTB front, 31" tires, Duraspark II, Offy C, EFI manifolds, Holley 390, No AC, 3G alternator, front receiver

|

|

Administrator

|

As Jim says, progress is good! And that means ANY progress.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Hi Guy!

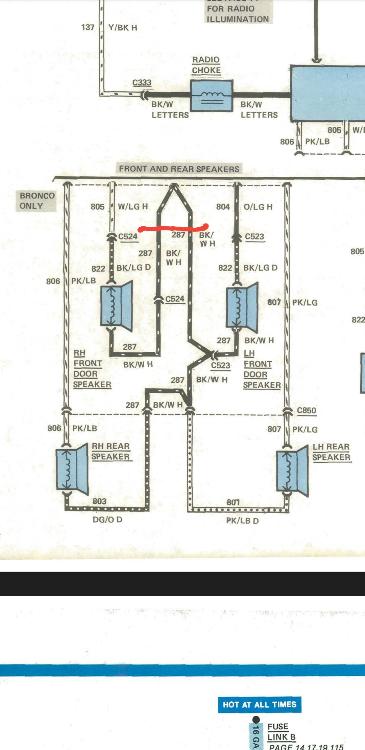

there has been progress on my block, Im now hopeful that Ill have it at the end of this month.  valves dropped into head. new seat have not been cut yet. I wired in my afr (I chose to run power from the starter solenoid post), and piped up my mechanical oil pressure gage. I also installed all of my new tailgate and rear glass seals as well as a new hood cowl seal. The tailgate window runs won the award for "surprisingly easy" and the tailgate corner seals kicked my butt. hopefully it wont rain inside anymore! at a minimum, it should be nice and quiet. On the cowl seal - I was surprised to find a bead of some kind of expanding rubber product behind my original. I didnt have anything like that on hand so I decided to do my best with RTV. Well, lets just say that worked out not nearly so well as I had hoped. I didnt make a mess and there is RTV behind the cowl seal but Im skeptical I managed to do any good. meh. the old one certainly wasnt doing anything. I can rework this one if it causes issues. Im on the lookout for one of the AC throttle kicker solenoid brackets for my 2150 it seems like most of them came on 2150 equipped 400 engines from the late 70s for whatever reason. If I cant find one easily and at a reasonable price Ill probably just buy a solenoid and fab a bracket. Ill be using manifold wrap to try to prevent my forward exh manifold from melting my alternator wiring harness again, Ill try to get that job done soon. I have an old oil cap that came on my JY powered by ford valve cover. its been soaking in DNA for a few days to loosen up all of the internal crud. perhaps today Ill pull it out, finish cleaning it up and paint it. I plan on using some hardware store hose to adapt it to a 3/8 bung breather. Ive been working on wiring in my new bluetooth amplifier. I purchased Coreys "radio delete" bezel (Thanks again Corey!). my plan is to mount the amplifier on a bracket that will adapt it to use the holes for the dash speaker directly above the radio compartment. Im somewhat concerned about the weight though as the amp is hefty. the real fun is in the speaker wiring though.  I expected to pull out the old radio and find 8 speaker wires. instead I found 4 hot, and 2 ground. ok.. so surely one one ground serves both front speakers and the other serves both rear speakers? or perhaps left/right? nope! One of the grounds serves the passenger door speaker and the other one serves all three of the other speakers (my harness had been previously cut at the red line). The new amp is 45rms Watts/channel, so there is no way Im leaving the factory 16/18 gauge stuff especially in this arrangement. layers of the onion, I think? The routing for the new wires for the door speakers is obvious but Im not sure what Ill do about the rear speakers. the "hot" and "ground" for the passenger door speaker both leave the radio headed towards the passenger door but the other ground and the other 3 hot wires all go to the driver side. I assume that the two hot lines for the rear speakers both go under the driver side door sill. Id rather route the new wires for the passenger side rear speaker through the passenger side instead of going under the flooring and across the cab from the driver side. does anyone know if there is a good route/way to pull wire behind the passenger side floor air vents, then go under the passenger side door sill, then up to the speaker? hopefully I can get all these extracurricular activities wrapped up before its time for me to CC my head. Thanks for reading! Take care!

1984 Bronco, mild built 300-6, Np435, 3.55 gears, 8.8 rear with Eaton TrueTrac, D44 TTB front, 31" tires, Duraspark II, Offy C, EFI manifolds, Holley 390, No AC, 3G alternator, front receiver

|

|

Oh - one other thing. My buddy and I are starting to try to figure out how we will put it all back together. Our preference is to fly the engine in first, the somehow crib the nose up in the frame so it doesnt flop down. After that, we need to get the bronco up in the air to make enough clearance for the transmission and jack to roll under. Once the transmission and engine are bolted up and the crossmember is in, it should be easy from there out.

Anyhow, when we were taking it all apart the crossmember gave us a hard time. We had the vehicle up un jack stands. The rear axles tube was on jack stands and the front of the vehicle was supported by Jackstands to the frame since we didnt trust putting it on the ttb arms. I think all of the cantilevered weight of the ttb may have put some twist in the frame making it very difficult to remove the crossmember. I need to crawl under there and see if the crossmember is easy to place/remove now. Anyhow, im trying to figure out a better way to support the front end so I dont put all of that load on two small points on the frame. Additionally, there will be about an extra 450lbs of weight in the nose this time making everything worse (engine was already out last time). Im considering the merits of cutting two 18" tall oak tree sections from a 2' diameter tree that fell at my grandparents place last year. Jack it up, set the front wheels on the stumps to unload everything. Bust em up for firewood when we are done. I know there has to be a smarter way than this though.

1984 Bronco, mild built 300-6, Np435, 3.55 gears, 8.8 rear with Eaton TrueTrac, D44 TTB front, 31" tires, Duraspark II, Offy C, EFI manifolds, Holley 390, No AC, 3G alternator, front receiver

|

|

If the truck can roll, maybe tow/push it up some Rhino Ramps?

1982 Bronco restomod in progress: Built 4.9L, T19 4spd, 9" 3.00 rear w/ Eaton TrueTrac, 31" tires, fuel injection soon

https://www.youtube.com/@jimjamauto |

|

Administrator

|

Getting it up on ramps would be good, but if you have tree trunks big and solid enough getting it up on them would work as well. However, do you need the rear up? That gets you closer to level and probably would make the engine installation easier. But it makes it all the more precarious. If the rear was still on the ground you could chock the wheels to ensure nothing moves.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

ramps would be excellent and I have 2 sets but I suspect the easiest way to get it onto ramps at the moment would be to jack it up. Gary, Im not sure on leaving the rear wheels on the ground. Id love to do the whole job with all four wheels on the ground but clearance to the frame is an issue with the transmission /transmission jack and my buddy and I aren't man enough to man handle the 435 up onto the jack laying under the truck. I would consider pulling the front clip, mating the engine and tranny and then flying it in all in one piece but we would need a substantially heavier engine hoist I think.

There has been more progress! I used fiberglass header wrap to wrap my front exh manifold, hopefully that will keep it from melting my alternator harness again. it turns out that wrapping that three into one manifold is not trivial to do cleanly, so I wont be gracing you guys with pictures. I suspect it will be very functional. my new valve cover came with an old rusty breather cap painted yellow. I soaked it in DNA for about 5 days then cleaned it up and painted it. A bit of hose has allowed my to adapt it to a 3/8 bung KN breather. sometimes the little things like that are the most stimulating and rewarding.  I abandoned the idea of mounting the new bluetooth receiver on the center speaker bracket, I think it weighs too much for that. Instead I discovered that there is just barely enough room on the firewall under the heater core and fan.  in this location the receiver will be invisible unless you put your head in the passenger side floor board, should have a decent heat sink in the form of the fire wall, and its weight certainly wont be straining anything. I have the power wired up through a relay to the battery and operated by power from the original radio power wire. another perk is that the area of the dash where the factory radio lived is now completely empty which leaves an ideal space for any future electrical projects. I also received a spool of new speaker wire, I plan to attempt to pull/ install that this evening if there is enough time after going to the engine shop to check on my block, hitting the grocery store, cooking dinner, and everything else.

1984 Bronco, mild built 300-6, Np435, 3.55 gears, 8.8 rear with Eaton TrueTrac, D44 TTB front, 31" tires, Duraspark II, Offy C, EFI manifolds, Holley 390, No AC, 3G alternator, front receiver

|

| Edit this page |