How To Calibrate A Speedometer

|

Administrator

|

Let me say right up front that I've not put this speedo in my truck and tested it, but I'm pretty sure it'll work perfectly.

Ok, with that disclaimer having been said, the following is how I think you can calibrate a speedometer on these trucks. From what I've read, the speedometer cable speed to show 60 MPH is 1000 RPM. So to do this you'll either need to have something with a known RPM or do some serious trial and error.

My lathe has a number of speeds and since it is gear-driven they should be pretty accurate. Unfortunately none of those are exactly 1000 RPM, but one is close at 1150. By my calculation that should make the speedo read 69 MPH. So in the first video at the bottom of this post is a test of a speedo I have and it read 67 MPH when driven at 1150 RPM. And in the second video you'll see that after tweaking the clock spring it does read 69 MPH.

And, just to check it out I shifted gears to a set that gives 890 RPM, which should show 53 MPH and it did. Then I went to 700, which should give 42 MPH and the speedo read 41. Finally I tried 300 RPM, which should be 18 MPH but the speedo read 12. So, while you can calibrate the speedo at a given speed, that doesn't mean it'll be right everywhere.

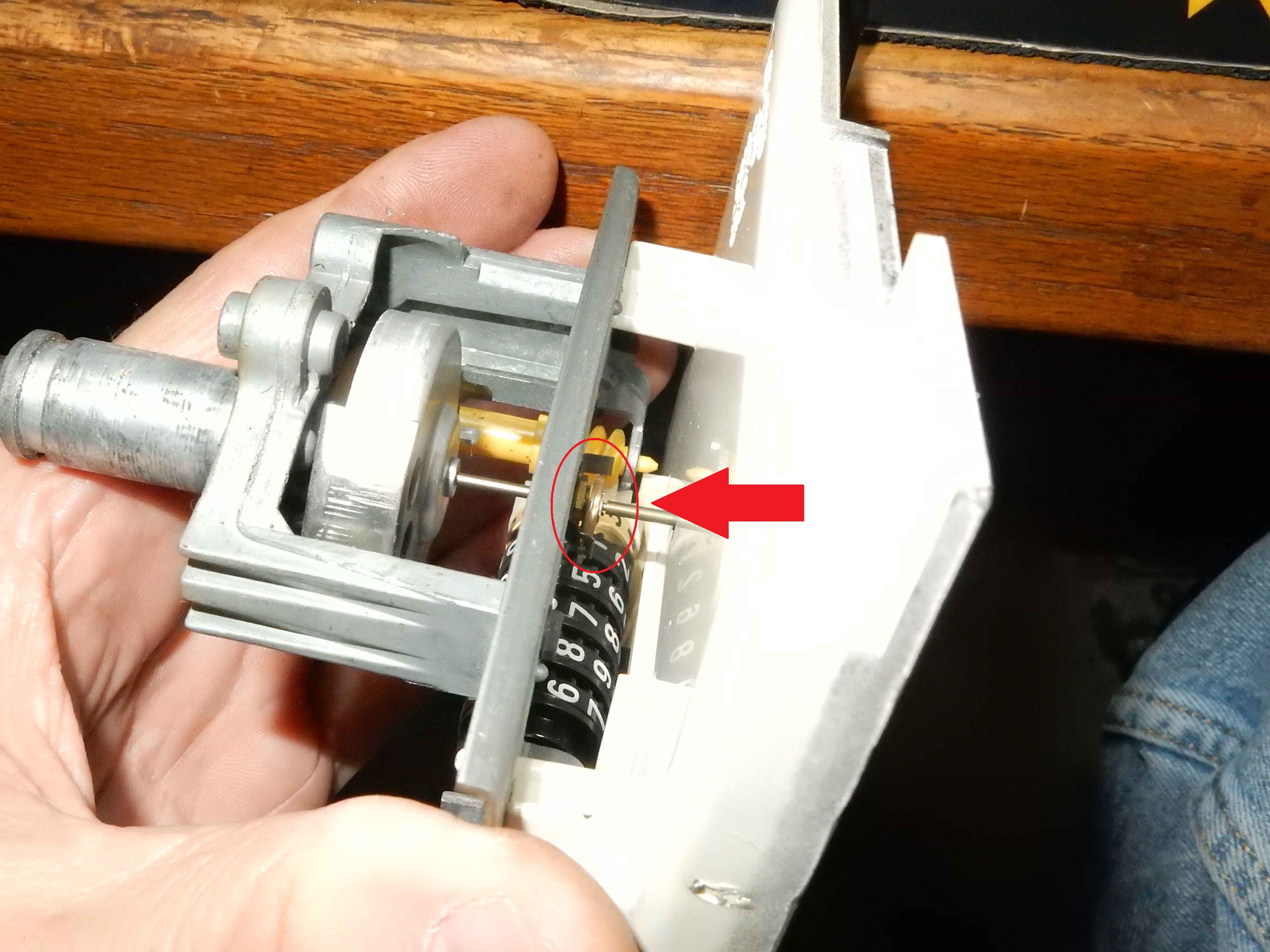

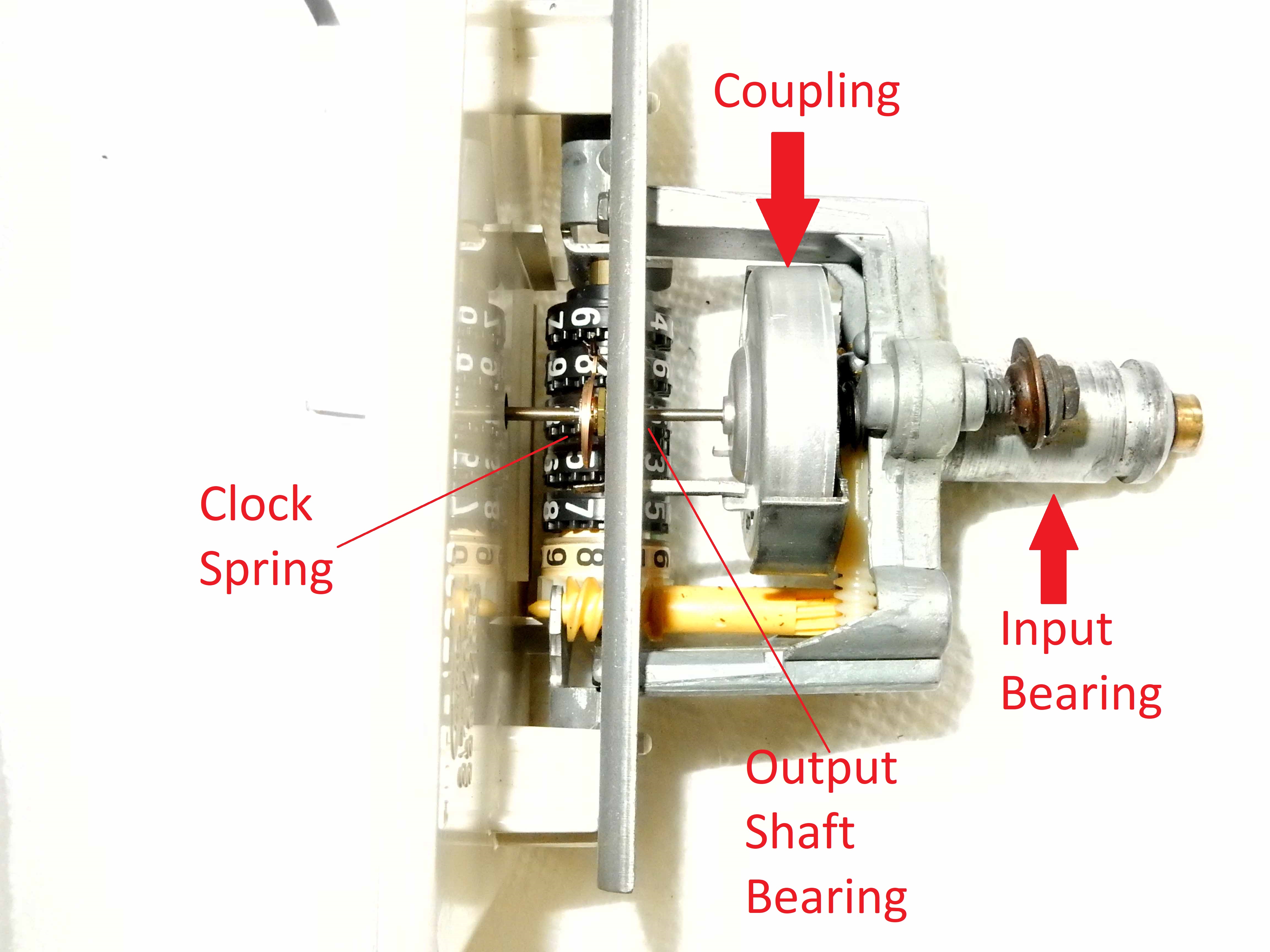

But, how do you calibrate it? You rotate the fixed end of the clock spring a bit. Where's the clock spring? It is in the circle here:

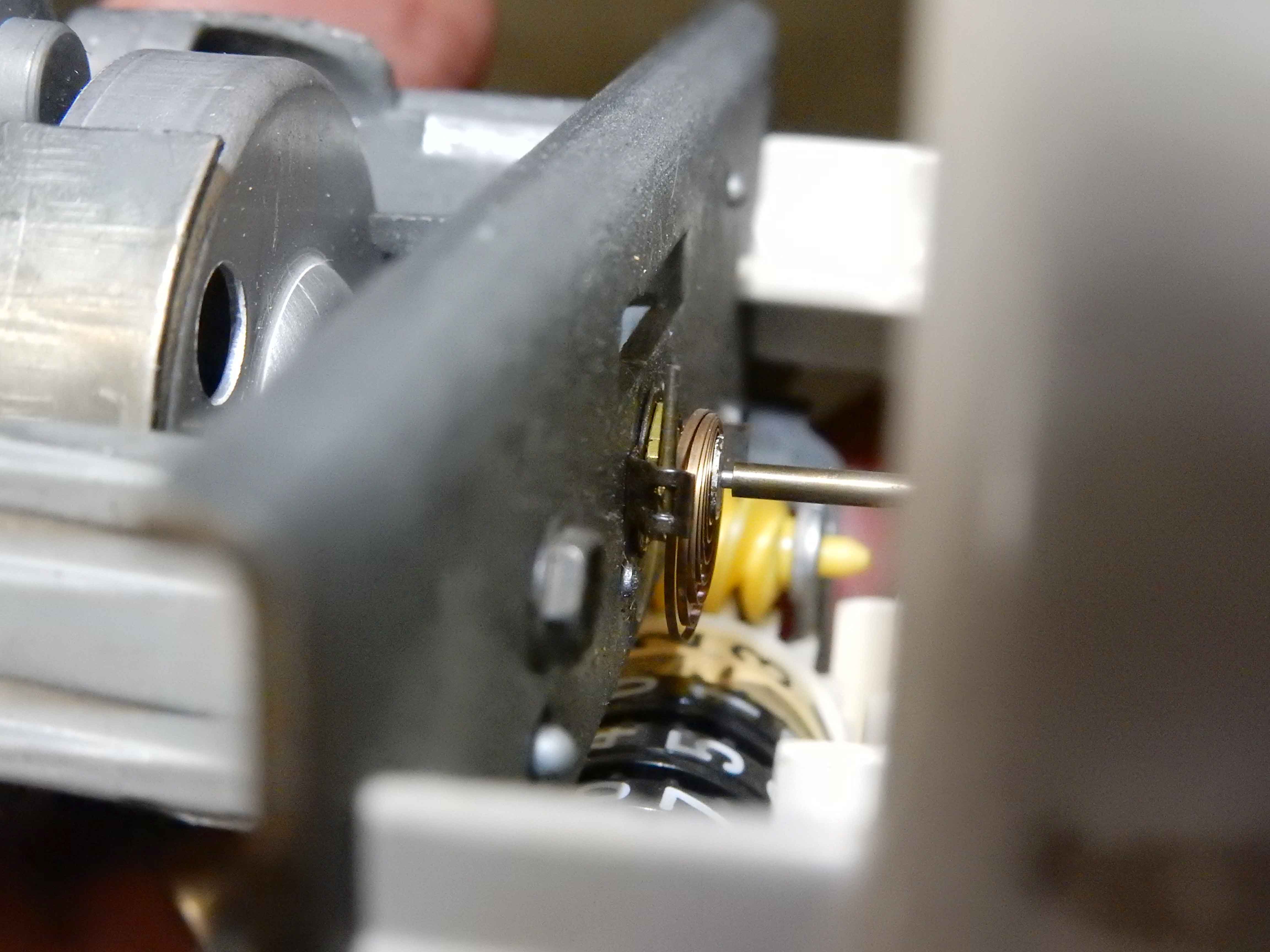

And here's a closer view of it:

And here's a closer view of it:

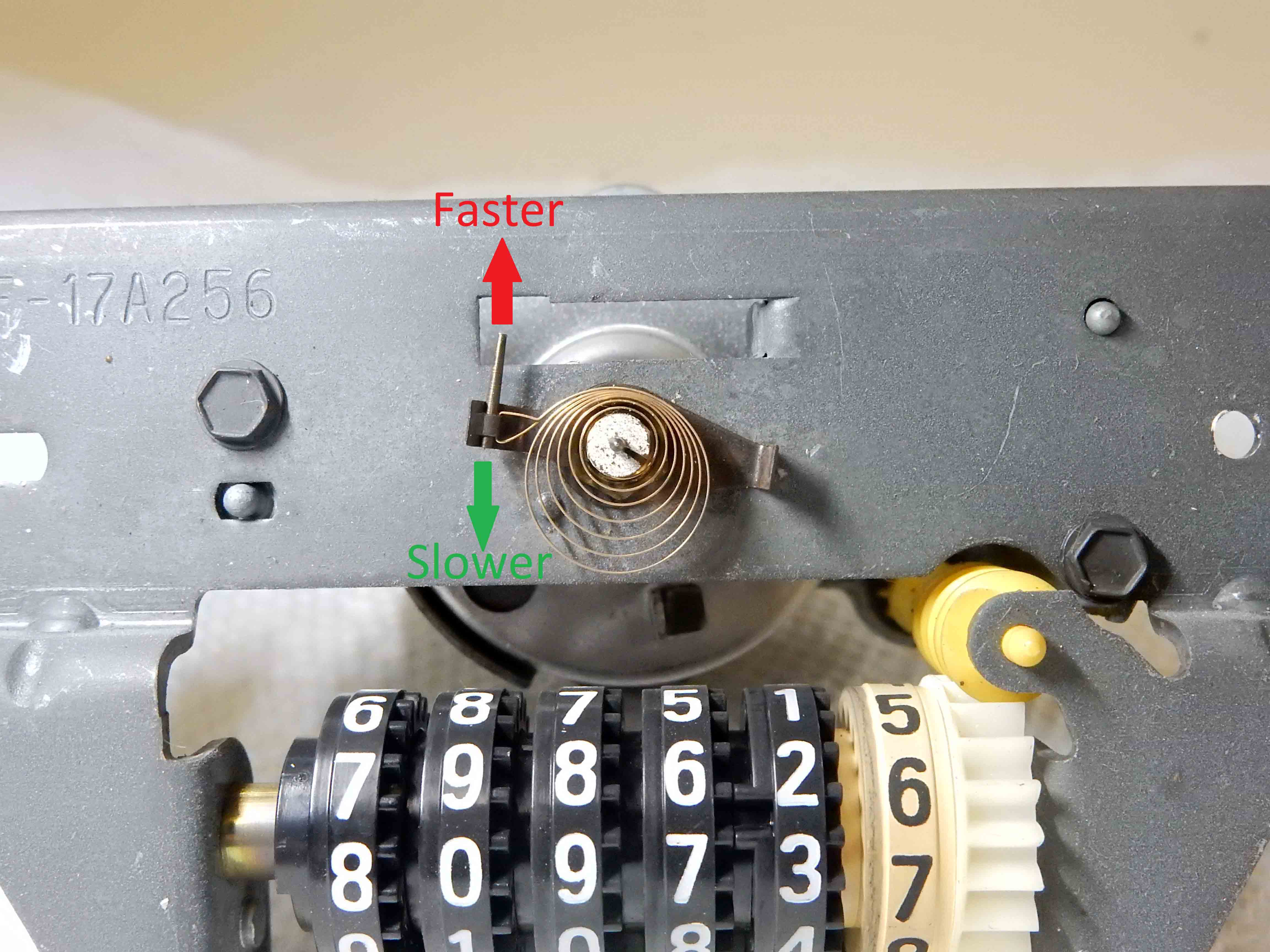

Finally, here's a view showing which way you rotate it to make it read faster or slower. BUT, you do NOT have to pull the needle and faceplate off to do the adjustment. I just did that so you could see how to rotate the arm. You can reach in with small screwdriver and slide the arm up or down, but try not touch the spring itself as it needs to be nicely coiled like this one is - now.

Finally, here's a view showing which way you rotate it to make it read faster or slower. BUT, you do NOT have to pull the needle and faceplate off to do the adjustment. I just did that so you could see how to rotate the arm. You can reach in with small screwdriver and slide the arm up or down, but try not touch the spring itself as it needs to be nicely coiled like this one is - now.

And, here are the videos. First, this one shows the initial test where the speed came up to 67 MPH instead of the 69 MPH target:

And this video shows the test after I tweaked the clock spring slightly and it comes right up to 69 MPH:

Maybe tomorrow I'll be pulling Big Blue's speedo in order to install the new speedo cable that's to be here tonight. And that speedo is off ~5 MPH at 30 MPH and up, so I'll be calibrating it and we'll then know how well the process works.

And, here are the videos. First, this one shows the initial test where the speed came up to 67 MPH instead of the 69 MPH target:

And this video shows the test after I tweaked the clock spring slightly and it comes right up to 69 MPH:

Maybe tomorrow I'll be pulling Big Blue's speedo in order to install the new speedo cable that's to be here tonight. And that speedo is off ~5 MPH at 30 MPH and up, so I'll be calibrating it and we'll then know how well the process works.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

Well look at you! Good way to put your engineering skills to work, my friend. Nice job, Gary.

Curious, what is your lathe?

John

"Blackie" - 1986 F150 4x4 - Mildly warmed over 351W HO - Original owner |

Re: How To Calibrate A Speedometer

|

Administrator

|

Thanks! It was fun, and something I've been wanting to try for a while. But since I need to pull the instrument cluster out of Big Blue to put the new speedo cable in I thought now was the time.

So I used a spare speedo I have just in case it didn't work.  The lathe is an Enco. Don't remember the size, but I can go look if you are interested.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: How To Calibrate A Speedometer

|

In reply to this post by Gary Lewis

Man that’s cool Gary!!! Love the how to! Got a few buddies with lathes so may have to check this out

Southern frame off 1984 f150, 70’ 460 and 4 speed toploader

Southern 1984 f150 pull truck, 600+ horse 460 np435 Southern 1992 beater f150 302 auto (for now) Californian 1983 bare bones f150 2wd {unknown plans} About 15-18 parts truck ahah |

Re: How To Calibrate A Speedometer

|

Administrator

|

Thanks, Chris. I'll post another video tomorrow of what I find with Big Blue's speedo. I expect it to read ~64 MPH instead of 69.

And, before someone says "change out the driven gear", I'm currently running a 16-toothed gear and don't see a 15 advertised. Besides, the odometer is pretty accurate with the 16. It is just the speedo that's off. So I plan to pull it tomorrow, test it, and hopefully calibrate it.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Administrator

|

In reply to this post by Gary Lewis

No need on the lathe, just curious. While we're on the subject of speedometer accuracy, do you have over sized tires on your truck? If so, how do you go about ensuring speedometer accuracy in those types of changes?

John

"Blackie" - 1986 F150 4x4 - Mildly warmed over 351W HO - Original owner |

Re: How To Calibrate A Speedometer

|

Administrator

|

I do have oversized tires on the truck. They are 33" tires and certainly change the speedo reading.

So your point is valid - I probably should have said that this approach will/should work if you have stock tires and gearing. But since my odometer is accurate then this is the only way to fix the speedometer error. As said, I expect to see ~64 instead of 69 MPH when I put the speedo on the lathe. Then I'll tweak it up the 5 mph and hope that it will read correctly when I put it back. But, I won't button everything up until I've taken a drive to prove the theory as I may have to come back and make further adjustments.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

Very cool indeed!

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

Administrator

|

In reply to this post by Gary Lewis

Agreed! Well done and well documented

Scott

'Camano' 1986 F250 Supercab XLT Lariat 460/C6 'Chanute' 1980 F350 C&C 400/NP 435 - Gin Pole But there ain't nothin' wrong with the radio |

Re: How To Calibrate A Speedometer

|

Administrator

|

Thanks, guys.

I plan to put this info onto the page at Documenation/Driveline/Speedometer Gears, Cables, & Sensors. And in the process of figuring out how to do that I took a peek at the calculators on that page. I'll have to confirm what my drive gear is in the t-case today, but if I put the 33" tire size into the Setup Gearing calculator I see that my speedo cable RPM should be 949 at 60 MPH. So instead of dividing my lathe's speed by 1000 to get the multiplier for the speedo reading, I need to divide by 949. That's a step I missed in the calibration procedure - finding out what your speedo cable RPM should be before adjusting the speedo. However, if you have stock gearing and tire sizes then you can probably assume 1000 RPM. And, I need to point out that this does not replace getting the right driven gear. Instead, this is for use when: You have the right drive and driven gears, but the speedo just reads incorrectly. For instance, on Big Blue the odometer is very accurate, so I have "the right" gears. But the speedo is off and I want to correct it.There is no driven gear to correct the speedometer. For example, if you have a 16-toothed driven gear and the calculator says you need a 15. Sorry Charlie, those are hard to find if they exist at all.But, are there other scenarios where calibrating the speedo is appropriate? Thoughts?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: How To Calibrate A Speedometer

|

Administrator

|

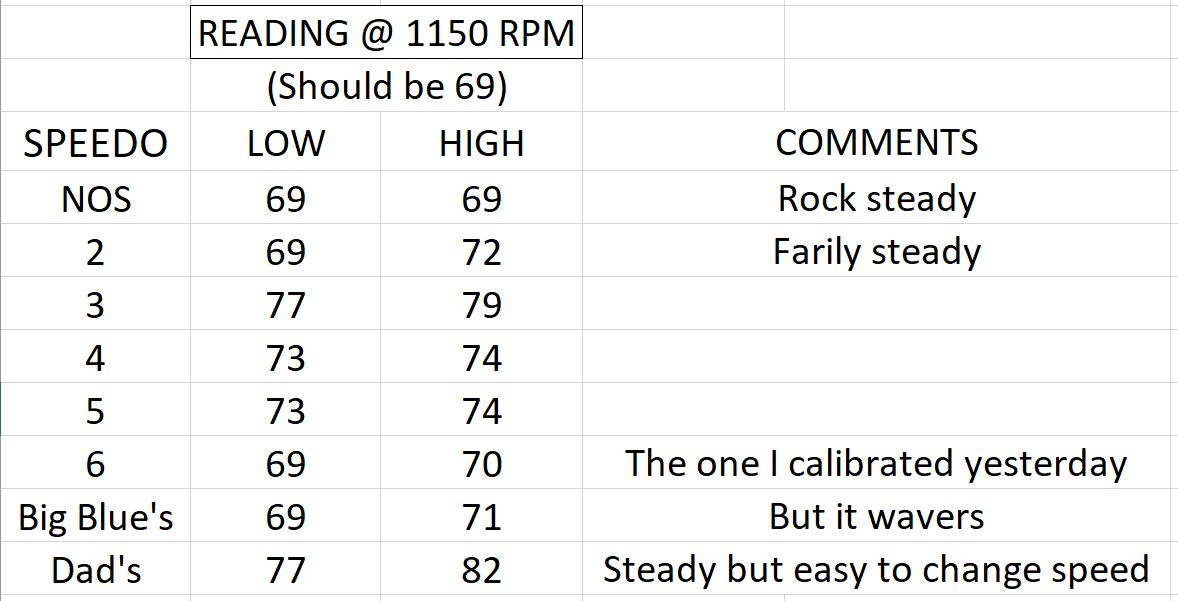

Well, the plot thickens. Today I pulled Big Blue's speedo off and tested it, only to find that it reads 69 - 71 MPH at 1150 RPM. You might think that's good since it is supposed to read 69 at that speed by my calculations. However, that doesn't explain why it reads ~5 MPH slow at anything above about 30 MPH.

I'll take that up in Big Blue's Transformation thread in a bit, but for now let's stick to the tests I ran today. After getting that result on BB's speedo I thought I should test several speedometers to see how they read. And as I was gathering them I realized that I have a NOS one, as shown below. So I pulled it out as well and tested 8 different speedometers. My thinking is that they should all read 69 MPH at 1150 RPM since you should be able to pull speedometers off the shelf and put them in service and get similar results. IOW, the speedometers should not differ in their calibration due to year or application. Given that, I was somewhat surprised by what I found:  Oops, I wasn't ready to post that. Yep, the NOS speedo read 69, as you can see below, although the angle at which I took the pic tends to make it look a bit lower than that. But the part that surprised me, beyond Big Blue's being pretty close, is that all of the speedometers but the NOS one could be sped up or slowed down by pushing on the cable a bit. Apparently that moves the spinning part of the coupling closer or farther away from the part that drives the needle, and some speedometers were a lot worse than others. On top of that, while most of the speedometers were somewhat stable in their readout, Big Blue's would bounce up or down at random times w/o me moving it or pushing on the cable. I'm thinking the bearings in it are pretty worn. Thoughts? Observations?

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

You said something about the bearings being warn.

What if they are dirty or the oil gummed up? The cable spins it and at a point over comes the dirt and it "takes off" and all that build up power for a lack of a better word, is re-least (reads high) and then it is back it normal or just below (normal or below reading) where it need more power to over come the dirt again. This keeps happening and that is the cause of the bounce. Hay it sounds good don't it  How many miles on each unit other than the NOS one? What kind of environment were they in? Windows closed and AC on (clean) or a farm truck, windows open and could grow corn because of the dirt (dirty). Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

Re: How To Calibrate A Speedometer

|

Administrator

|

Dave - While Big Blue's speedo has always fluttered or bounced while driving, all the tests I'm talking about where I saw differing readings were done on my lathe, which has a 2 HP AC motor feeding through gears. And the speedo shaft was only about 4" long. So I'm confident there was no variation in the RPM.

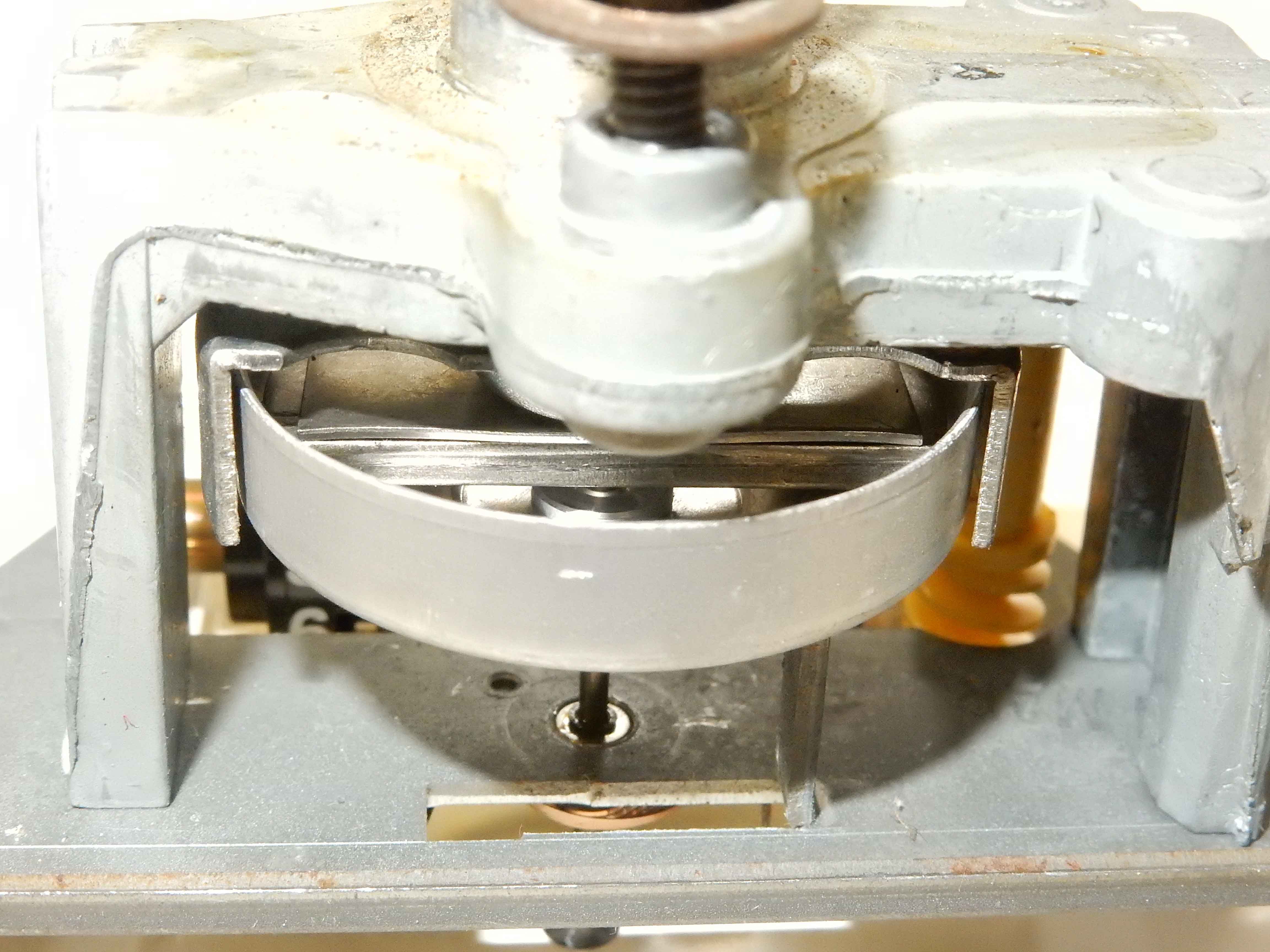

As for the condition of the speedometers, they were all remarkably clean inside. No oil, no dirt, NADA. But let me explain my previous comments. The pic below shows what I'm calling various things. The coupling has no physical connection from the drive side, on the right, to the driven side, on the left. It appears to use air as the medium to transmit torque to the driven side, and that is balanced by the clock spring, and the bias on it is what "calibrates" the speedo. As you'll see in the next pic, the tolerances are tight in the coupling, so I'm thinking that over the thousands of miles the input bearing has worn, allowing the drive part of the coupling to get closer or farther away from the driven part. And that fits as when I pushed on that brass part of the input shaft on the far right I could cause the speed to go up or down some depending on which way I pushed.

As said, the tolerances are pretty tight in the coupling, but none of the ones I have are dirty in there at all. No oil, grease, dirt, etc. So the only thing I can come up with that would change while the input shaft is spinning is the position of the shaft. And, as said, pushing on it certainly caused changes in the readout on all but the NOS speedo. Also shown in the pic below is the output shaft bearing. I thought that it being dirty or dry might make a difference so I lubed Big Blue's with a very light machine oil, but that made no difference that I could detect. So I think the wear is in the input shaft's bearing.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: How To Calibrate A Speedometer

|

The piece spinning inside the "coupling" is magnetic and when it starts spinning it drags the outer shell, what you're calling the coupling with it, with tension provided by the spring, giving you a reading on the speedometer.

1981 F 150 Custom 300 ci with a fully rebuilt 1968 240 head Carter YFA T-18 3.25 9" rear 2WD

dual gas tanks 1990 Lincoln Town Car 5.0 AOD Home town Mc Kenzie, TN |

Re: How To Calibrate A Speedometer

|

Administrator

|

I'm calling the coupling both halves - the drive side that connects to the speedo cable, and the driven side that connects to the speedo needle. And none of my 8 speedo's appear to use magnetism as the driven shell is aluminum. Or at least isn't magnetic. And a probe with a screwdriver shows that the arm isn't magnetic.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: How To Calibrate A Speedometer

|

Administrator

|

Aluminum is repelled by magnetism and the spinning magnet in the bar generates a small current in the aluminum cup, the faster the magnet bar spins, the greater the force exerted on the cup. One of the common problems with older vehicles, the magnet looses strength and causes the readings to be low. Speedometer rebuilders either install a new magnet or re-magnetize the old one.

I do not remember, other than a few Mercedes-Benz ones I sent off where they went. There used to be a couple of places in the Tidewater VA area that could do them locally.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

Re: How To Calibrate A Speedometer

|

Administrator

|

So Frank is right and it IS due to magnetism, even though I can't get my screwdriver to be drawn to the arm? And even though the driven cup is aluminum?

Sorry for doubting you, Frank! But you two are certainly teaching me some things.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: How To Calibrate A Speedometer

|

Administrator

|

Gary, I did a quick search this morning and came up with these: https://www.google.com/search?q=mechanical+speedometer+repair&oq=Mechanical+Spee&aqs=chrome.2.0i457j0l2j69i57j0l4.10648j0j15&sourceid=chrome&ie=UTF-8

I remember now what the last speedometer I had to deal with the magnet on was, it was the one for Matt's 1965 Corvair Corsa. Either the worm for the odometer drive or the bearing in the casting was bad (FWIW the rpm to mph on those is completely different due to being driven by one front wheel) I obtained an NOS one from one of the two big Corvair parts sources and found out it was not magnetized. The shop in Newport News solved that for me.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

Re: How To Calibrate A Speedometer

|

Administrator

|

Bill - Thanks for that. I didn't go very far in the list of search results, but saw one that called the speedometers "eddy current speedometers". So I Googled "how an eddy current speedometer works" and found this one to be pretty good: Explain That Stuff - Speedometers. And the pertinent parts for a mechanical speedometer are:

At the top end, the cable feeds into the back of the speedometer. When it rotates, it turns a magnet inside the speedometer case at the same speed. The magnet rotates inside a hollow metal cup, known as the speed cup, which is also free to rotate, though restrained by a fine coil of wire known as a hairspring. However, the magnet and the speed cup are not connected together: they're separated by air. The speed cup is attached to the pointer that moves up and down the speedometer dial.

And that has really helped me understand speedometers. Many thanks to you and Frank.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: How To Calibrate A Speedometer

|

Administrator

|

Now all you need to do is pick a speedometer and send it to one of the rebuilders and have it overhauled and calibrated.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

| Edit this page |