Search Forum

CAD - Modeling and Manufacturing Prints

12

12

Re: CAD - Modeling and Manufacturing Prints

|

Administrator

|

Yes! Now I understand. Thanks, guys. I'm a bit slow. And you could put a zerk fitting in the Z-bar. Or use one of the Teflon-lined inserts.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by ArdWrknTrk

I have not stayed up on all this new tech and if you blink you are left way out in left field. Yes Wright Tech class of 78 I went thru the auto shop, years before they built the body shop, I already knew how to do body work. If I did not go the auto side I would have done the tool & die as I enjoyed that. The upper classmen of the T&D were just getting in to the CNC programing side. I had an uncle that did T&D work. I was told proto jobs & setups for long job runs. I wished I could have learned some from him before he passed. Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

In reply to this post by Rembrant

You can still get the nylon bushing for both sides along with the felt washers to keep dirt out and the snap ring that holds the bushings to the part. Little back ground, when I got my truck the bushings were gone and for a long time from what I had seen and the metal part the bushing fits on was warn away. I had to weld up the metal and reshape it so the nylon bushing would fit again. In moving the truck around that metal part the bushing fits on broke front the threaded part, this should be all 1 piece. I took a bolt of the right thread pitch, cut the head off and welded the threaded part to the bushing part making it 1 again. That would have been it but the welder (me) did not do a good job and the threaded part broke off the bushing part. I did the same fix with the bolt but I drilled a hole thru the center and drove a roll pin in to help make it strong in the center and turned up the heat on the welder this time. In short it is the metal part with the threads the nylon bushing fits on is what is needed as they can't be had any more. Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

In reply to this post by Rembrant

Yes, Cory sent me his 300 6 pivot ball. Its on the work bench.

Ive not put much thought into this yet Jim, but I am sure we can improve the design. I will take a look at the one in Little Blue 82 this week and formulate a better design. Welding bolts should only be a temporary fix. Im no metalurgist, but I have a tiny bit of understanding of heat treating and material properties. When I worked for Remington Arms R&D we had a SLS. we printed gun parts. If I remember correctly, a printed part was wire EDM'D off a base plate that it was lasered to, and the part after heat treating could gain strength, but was maybe 90% of the material strength as a part machined from billet....FWIW.

1988 F250 Supercab Longbed 7.3 IDI, C6, 1356, GEARVENDORS, 4.10 Sterling with autolocker

1986 F150 302, C6, 9" 2.75, Wood Flatbed |

|

In reply to this post by Rembrant

Too bad you couldn't get one of those balls made of solid steel coated in NP3, and booted. It would last until the second coming.

1986 F-150|Standard Cab|4x2|300Six|C6Transmission w/3.08 rear|Name:TBD

2021 Ranger XLT Super Crew |

Re: CAD - Modeling and Manufacturing Prints

|

Administrator

|

In reply to this post by Ray Cecil

This stud seems incredibly simple to churn out on a NC lathe.

Material and post process treatment (heat treat, shot peen, polish, surface coating?) should be enough. The suggestion of booting it seems helpful too. I guess I was thinking of Gary's dad's trucks pivot, where it seems to mount at the edge of the bell housing. A shape like that could be iterated. Look at those Buggatti calipers. They cannot be 5-axis machined from billet.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

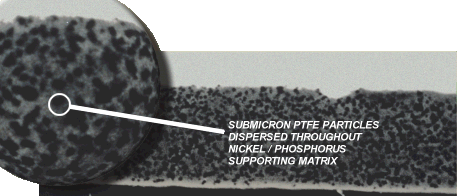

if you churn one out you can send it in for NP3. Its a composite layer of nickel, phosphate, and PTFE(Teflon). Its extremely hard and permanently self lubricating "if" the surface wears it just exposes more Teflon and continues on. It would be awesome to see an engine done with NP3 coated internals. Externally anything coated in NP3 will not corrode even in salt water. I actually have some high use firearm internals coated with this stuff. You may not even need the bushing lol, just cut it to the same dimensions and let it ride. Or use another solid metal bushing NP3 coated.

1986 F-150|Standard Cab|4x2|300Six|C6Transmission w/3.08 rear|Name:TBD

2021 Ranger XLT Super Crew |

Re: CAD - Modeling and Manufacturing Prints

|

Administrator

|

I have a few pistols with various coatings as well.

Look at Calico Coatings in Maine for engine internals. Piston crowns, combustion Chambers and valve heads in heat rejecting ceramics. Cams, lifters, rockers in ultra hard and self lubricating coatings. When you have multi-million race budgets, anything to reduce losses is possible

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

Bullnose Enthusiasts Forum

›

Resources & How-To's

|

1 view|%1 views

| Edit this page |