Muminvaters F250 scale 1:13

|

moin moin,

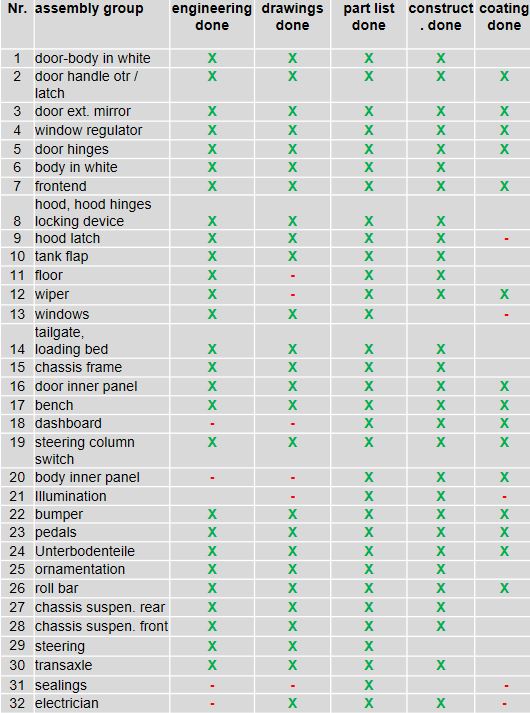

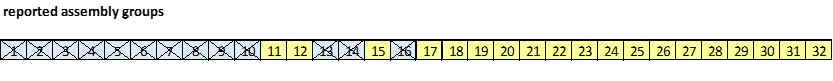

(as we like to say in northern Germany = short form from good morning/evening)  The Ford F250 project began in 2012 with 2 years break inbetween (for a Golf 1 convertible 1:25 with a movable roof btw). In the beginning, the request to the model was not in this way like today. First, it should be enough to open the closures, to illuminate the head and backlights and to make the wipers work. Of course, at the body was a lot of work, because the purshased body was Generation 9 and I had to bring it back to Generation 7.  Helpful were a lot of pictures from the web and a brochure from 1982 I ordered in USA with have much better photos. Only years later, when I engineered the chassis frame, I discovered the bullnose website. Ok, I said multi-funktional and I will start with a list of it´s: Exterior - Doors open, doors turn into the body - Door windows can be lowered - Rotatable triangular windows of the door - The hood can be opened via the Ford logo, self-determining - Tailgate to open and remove - Open the fuel filler flap and remove the fuel filler cap - fillable fuel tank - functional wipers, switchable via dashboard - swing away exterior mirrors - Rear sliding window with snap lock - Spare wheel can be removed from the holder Chassis suspension - Chassis frame - Dana44 front axle - Coil spring - Viscous damper - front axle (fake) differential - 2 Twin-Beam - 2 Radiusarm - steering trapeze - Rear axle - Leaf springs - Viscous damper - Rear axle differential - transaxle - Verteilergetriebe (I didn´t found a translation) the gear behind the automatic transmission Interior - folding seat backrest - Adjustable inner mirror - 2 seatbelts, similar function as automatic belts - 1 adjustable lap belt - Glove box to open and illuminated - functional internal ventilation/ Fan, switchable via dashboard - folding and swiveling sun visors Exterior illumination - 2 Headlights in front, 2 rear taillights, switchable via dashboard - 3 high beam headlights on roll bar, switchable via dashboard - Brake light, switchable via brake pedal - Turn signal, switchable via turn signal lever, front, side, back, Flashing frequency as with the original - Hazard warning lights, switchable via shift lever - Rear license plate light, turns on with headlights Interior illumination - Interior lighting is controlled by opening the doors - Instrument display, turns on with headlights - Glove box lighting is controlled by opening the box All these points are already done. Following the List of assebly groups and their progress.  That´s enough for today  In the next step I report of preparing CAD Data, the purchased modelpieces and then it starts with jpegs In the next step I report of preparing CAD Data, the purchased modelpieces and then it starts with jpegs  greetings, Tobias

_____________________________________________________

Winter winds take flight, circling over my grave. A haunting voice amidst the trees, rising up across the sea.... (Katatonia) _____________________________________________________ |

|

Administrator

|

Welcome Tobias!

Do you have the body builders layout book? https://www.garysgaragemahal.com/1985-body-builders.html This may be of interest to you, or perhaps it can simply confirm measurements you already have.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

|

Administrator

|

Man, of man, that is a lot of WORK!!!! I can't wait to see the results. I hope you you videos of the doors, hood, windows, etc opening, the wipers and lights working, etc. We can post videos here, so please let us see them!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by ArdWrknTrk

many thanks for the layout!!

Should have this years earlier Should have this years earlier  Comparing the layouts with the model may lead to disassemble the model and modify it Comparing the layouts with the model may lead to disassemble the model and modify it  and I´m not sure I´m ready for that.... and I´m not sure I´m ready for that....

Some things, with are not in scale, are the tribute to the feasibility (eg the trans case = Verteilergetriebe) Tobias

_____________________________________________________

Winter winds take flight, circling over my grave. A haunting voice amidst the trees, rising up across the sea.... (Katatonia) _____________________________________________________ |

|

Administrator

|

Gary has compiled a tremendous amount of documentation for these trucks.

It's the goal to share this information with everyone who has an interest. I understand how it may be impossible for you to create functional/durable parts at 1:13. I hope you will share some of the interesting and challenging aspects of your model with us.

Jim,

Lil'Red is a '87 F250 HD, 4.10's, 1356 4x4, Zf-5, 3G, PMGR, Saginaw PS, desmogged with a Holley 80508 and Performer intake. Too much other stuff to mention. |

the other way round I hope to benefit from your experience to influence my model.

_____________________________________________________

Winter winds take flight, circling over my grave. A haunting voice amidst the trees, rising up across the sea.... (Katatonia) _____________________________________________________ |

|

In reply to this post by muminvater

hello to you

The beginning of it all was, of course, the purchasing.

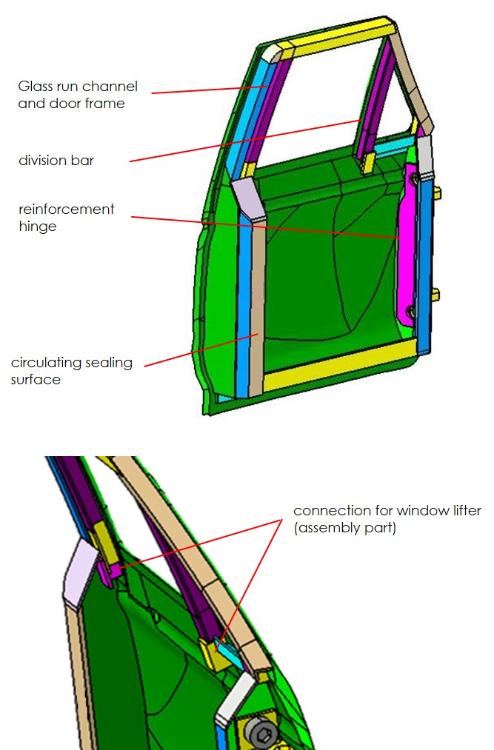

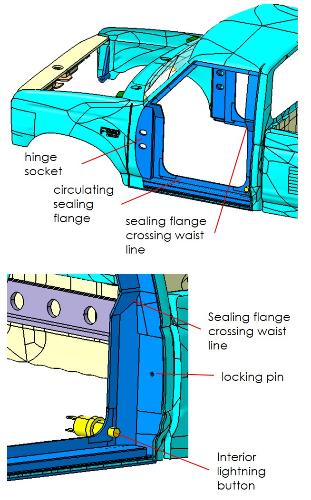

1.body: Tamyia Blackfoot Xtreme (9. Generation) 2.Frontend: Tamyia Blackfoot 3 (7. Generation) 3.Bumper: Tamyia Blackfoot 3 (7. Generation) 4.Interieur: Tamyia Toyota Bruiser, seats and dashboard 5.Chassis: Tamyia XC/CC-01 From a technical point of view, it was crucial that the Ford has wide structural flanges on the door side and a triangular window which greatly alleviates the problem of lowering the door glass / hinge. The door shaft is deep enough to lower the door glass completely. In addition, the hood is designed so that it can still be opened with a 2-point hinge. The cross-country 4WD chassis is fully off-road and fits the wheelbase to 2 millimeters. The classic design of the Ford F250 (7th generation) and the possibility of converting the Xtreme (9th generation) to it were optically decisive. Later i realized that the chassis was useless and I engineered a scaled one. PREPARING 3D Scanning First, the body of the model had to be scanned so that any CAD-compatible material was available. For this I was allowed to use the company equipment in the form of a 3D laser scanner.  1. This is the 3D scan point cloud. 2. Revised polygon surfaces that have to be converted into CAD compatible surfaces. I use CATIA V5 R19 as the CAD system 3. CAD capable (4-sided) surfaces. With a disastrous patch breakdown. The manual division was too time consuming. Only the hood has been redesigned. Section cuts Next step was to create a lot of section cuts and to find a concept. It´s much easier to do it bring your ideas on paper first than on CAD, so I did.   This is an example for the ergonomic-section cut. You see the diffrent fix points: hip-point, eye-point and the size of the figure (95% man). And you see the field of view. I think in reality there would be no chance for a registration certificate  MANUFACTURING  First job that had to be done is cutting out the closures.  assy group 1 / door    To open the triangular window, the A-pillar cowl frame (1) must have a cutout. The lower pivot point support (2) also had to be an assembly part. The A-pillar cowl has a 0.5mm thick foam rubber layer (3). This conceals irregularities in the parallelism of the glass and the body and allows the window to close better.  The difficulty with the fitting is that the A-joint is an engineered joint, i.e. the contour of the joint results from the design of the body and the hinge axis. The joint and the design were already specified for the model. And with the position of the axis you don't have too many options to play with. This resulted in the joint pattern shown above after the first adjustment. The first changes were the reduction of material on the fender on the body side and a chamfering of the door frame along the A-pillar and the roof frame on the door side. The hinge also had to be rebuilt because the old one was too far forward. The bottleneck at the top could be remedied by adjusting the new hinge. For the lower one, it was absolutely necessary to move the joint to the front.  The door has been extended forward so that the joint is parallel again. The same procedure applies to the right side. So the door turns into the body, just like the original  The sealing flange of the body also had to be adjusted again, course the two flanges, door and body, were not parallel. I hope, I do not wrote too much  Next step ist assy group 2 and further. Next step ist assy group 2 and further.

see you, Tobias

_____________________________________________________

Winter winds take flight, circling over my grave. A haunting voice amidst the trees, rising up across the sea.... (Katatonia) _____________________________________________________ |

|

Administrator

|

First, you do not write too much! Please keep it coming.

Second, wow! That is a lot of very, very precise work! Well done!  I can't wait to see how this all comes out, but it is looking really, really good.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

Re: Muminvaters F250 scale 1:13

|

Tobias, what a precision work!

I am very impressed with your project! Good continuation in your passion and, please, keep feeding your thread!

Jeff / 1984 F350 Crew Cab 4x4/5.8L w351 4V/ T18/ D50 4.10 front/ 8' bed.

Restored 2019-2022. Nicknamed «Big Brother 1984», due to its soooo-looong shape & nod to George Orwell's 1984 famous novel. |

|

In reply to this post by muminvater

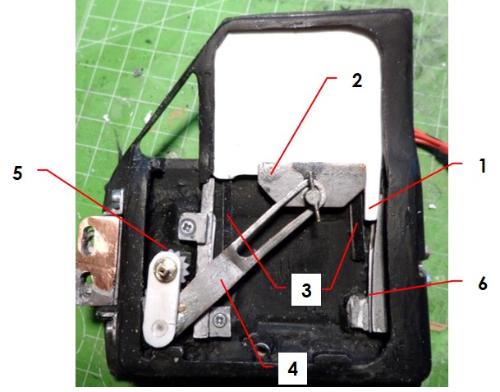

Here we go again… (white snake)

assy group 2 / door outer handle / latch  The ordered door handle (the lower handle in the upper picture) had to be shortened in two dimensions: on the one hand, it was too long and, on the other hand, it is too far outwards. The beautiful bracket had to be omitted and replaced by a simple 4-cornered handle block.  can adjust it exactly on the desired closing force of the door. On the left side the latch-plate with M2 screws with a minimized head. Right next to it you see the opposite part, the threaded plate. Left side lower the latch with the locking bolt with will be mounted to the body. Via the thread you can exactly adjust the door on the desired closing force. assy group 3 / exterior mirror  Auxiliary tool for bending the mirror arm. 1. Prototype in circular geometry  The finished „swing away“ exterior mirrors. The protective film is still on the mirror surface, which is only removed after painting. Fastening screws and nuts in size M1.2 are amazingly durable. assy group 4 / window lifter  For assembling the window the glass run channel front is removable  The window grabber is a copper-brass construction that clips into the glass. A square tube is soldered into the axle of the small drive gear wheel for torque transmission.  For trouble-free lowering/lifting the window a lot of fine-tuning was necessary. 1. Modifying the cut offs or boundaries of the glass to avoid an tilting of the window. 2. The window grabber moved 5mm backwards 3. On the outer side of the window, I added 2 wedges to harmonize the lowering/lifting. 4. The lifterarm received some deformation 5. I tried different gears with different modul (do you use this word to calculate a gear in USA?) 6. At last I had to remove the coating out of the glass run channel. It turned out that the metallic paint had a significant (bad) effect on the gliding behavior. Instead, a layer of flocked paper was glued in. assy group 5 / door hinge the second hinge, you see the first one in some pics of the assy group 1. assy group 13 / triangle window  Why the window rotates with the offset axis is not quite clear to me yet. In any case, it did not work with an aligned axis. The holes are 0.5mm larger than the pins, so that the window axis has enough clearance. assy group 16 / door inner trim  The door inner panel is an assembly part as well. Hooked behind the doorplate at 3 positons, you have fix it with 2 screws. The back has a smooth surface so that the lifterarm can not jam. ________________________________________________________________ So, that´s the door  A lot of stuff. While translating my reportbook I myself was astonished about the amount of parts A lot of stuff. While translating my reportbook I myself was astonished about the amount of parts  enjoy reading, post your impressions and also your criticism, greetings Tobias

_____________________________________________________

Winter winds take flight, circling over my grave. A haunting voice amidst the trees, rising up across the sea.... (Katatonia) _____________________________________________________ |

|

Administrator

|

Very impressive! The wing vents (triangular windows) pivot on the lower axis and an upper pivot that is hidden. They do tilt slightly when opened due to the inward slant of the door top.

I would get you some pictures, but I updated my interior to a 1996 interior and had to go to the squared off front on the wing vents to clear the driver's end of the dash where the instruments are. The translation you were trying to find for the piece behind the transmission, is probably "transfer case" where the drive for the front axle and the 4WD shift and Hi-Lo range shift takes place.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Hi Bill,

some pics of the wing vend sounds good but if it doesn´t fit in case of your modified dashboard/interior doestn´t matter. In the model it works quite good The translation ist trans case. Ich watched it up in the bullnose website

_____________________________________________________

Winter winds take flight, circling over my grave. A haunting voice amidst the trees, rising up across the sea.... (Katatonia) _____________________________________________________ |

|

In reply to this post by muminvater

Very nice! Impressive!

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

Administrator

|

Wow!

Scott

'Camano' 1986 F250 Supercab XLT Lariat 460/C6 'Chanute' 1980 F350 C&C 400/NP 435 - Gin Pole But there ain't nothin' wrong with the radio |

|

This post was updated on .

In reply to this post by muminvater

hello to you,

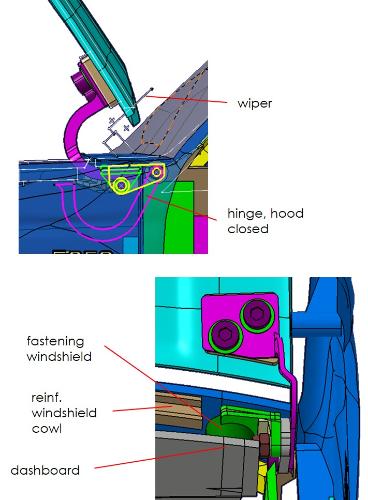

let´s go on with assy group 6 / body in white  Manufactured individual parts according to drawing and part – assemblies.   I shaped the components with 3-D contours using an embossing heat tool. The air flow of the embossing heat tool is, depending on the model, between "only" 130°C/266°F(my model) and 200°C/392°F and thus benefits the low melting point of ABS / styrene. A hot air gun, on the other hand, has an air flow temperature. The original from 1980 - 1986 was not available with a glass or sliding top, the cutout must be closed.  Of course, the typically large trim strips over the wheel arches of the 7th generation should not be missing. After a smooth warming with a hair dryer, the trim strips could glue on tension free. assy group 7 / front end  The front cross member was installed and the fenders lengthened to the front. 4 screwing positions for the frontend assembled, 2 in X und 2 in Y direction. The side of the front end had to be shortened and the lower fastening was installed.   The central recess in the body had to be widened for the ventilation grille. It´s depth is exactly right for a 1mm plate .  The front end of the Tamyia Blackfoot 3 should be the starting point. Milled out for indicators and headlights as well as for the original F150 grill. Grill grid inserted and hole for the hood opener. Movable Ford logo with compression spring prepared as a hood opener. Gauze in anthracite and a coarser grille in black above provide the radiator fins optics.  Then the grill had to be revised again: the individual ribs became a little thicker. The grooves shown above were created on the mill so that the distances are identical everywhere. assy group 8 / hood, hood hinges locking device  Of course the tuning hood must be removed and the area rebuilt. At the same time, the holes for the mounting domes were also closed. on the right picture the central bead was rebuilt and pulled over the entire hood. Then a test coating was done.   Saw off the curve of the hood of the 9th Gen. The sloping surface at the front contoured under heat. Reinforced beading on the middle of the hood and modified the fenders.    The mounting plate (3) with the 2 pressed-in threaded pins was glued to the body with 2-component resin adhesive. The length of the hinges (1) could be adjusted via the elongated holes in the screw bracket (2), but they still needed some readjustment in terms of angularity until the hood was where it should be.   As like the origin, two locking devices are installed. If the hood is in the end position, both locks automatically fall into the locked position.  That´s it for today  wish you a nice rest of the weekend wish you a nice rest of the weekend

_____________________________________________________

Winter winds take flight, circling over my grave. A haunting voice amidst the trees, rising up across the sea.... (Katatonia) _____________________________________________________ |

|

Administrator

|

Guten abend. That is mighty impressive work.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

hi Gary, thanks but this ist "warm up"

My favaorite are assembly group 9 (hood latch) 19 (steering column switch - google translator) and, of course 27+28 front and rear axle. My favaorite are assembly group 9 (hood latch) 19 (steering column switch - google translator) and, of course 27+28 front and rear axle.

they were all tricky

_____________________________________________________

Winter winds take flight, circling over my grave. A haunting voice amidst the trees, rising up across the sea.... (Katatonia) _____________________________________________________ |

|

Administrator

|

I can’t wait for the real thing!

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

|

In reply to this post by muminvater

moin moin,

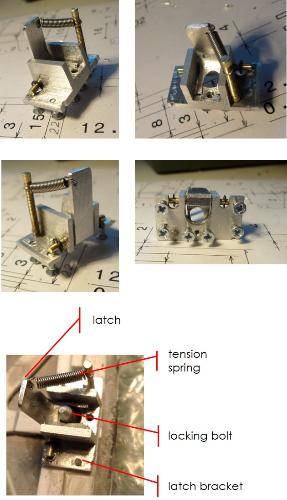

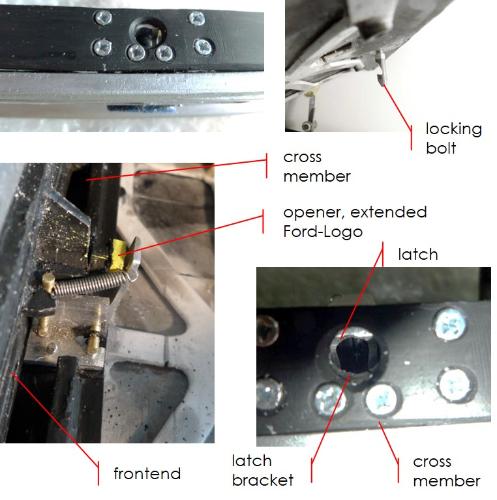

to complete the body, I go further with no 14. assy group 14 / tailgate, loading bed   To open the tailgate, the loading bed (is it the right expression? In German I use Ladeboden) necessarily has to move about 18mm lower. Then you get a planar surface with the opened tailgate. Lowered loading bed, new bigger wheel housings glued and spackled. Holes and tool-related cut outs were cleaned up at the same time. The wheel housings are one of a few parts out of a 3D printer.   Tailgate unit sawed. The backlights must be build new as mountable modules. The tailgate itself has to be modified to the design of the year of manufacturing 1982 and completed with hinges. Joints spackled and sanded. Ornamentation out of the 3D printer glued  Milled hinge parts and for a demountable tailgate 90° angled axis. The body-sided hinges are glued in a bed of the 2-component aluminum filler. And now, the opened tailgate and the loading bed are on the same level.   Millings for latch and handle fastenings were done. Adjustable clipping for the tailgate via Allen screw with a spherical grounded head. On the opposite side on the tailgate, there is a Aluminum plate with a drilling, in with fits the head of the Allen screw.  Only much later did I find out that the loading bed of the original is not smooth, but pushed through to the outside. So the surface had to be cut out again. The panel was then moved outwards so that at the waistline a 90° folded flange could created. The beading was reproduced by doubling. assy group 9 / hood latch   The locking bolt of the hood dips through the hole in the cross member and meets the fork-shaped recessed lock latch there. The latch is so narrow that the locking bolt only fits through when the latch rotates in its mounting. This is triggered by the wedge-shaped molding of the locking bolt. When the locking bolt is dipped deep enough, the tension spring snaps the latch back into the recess of the locking bolt and thus locks the hood. The lock is only opened again by pressing the Ford logo, which tilts the latch back a little below the spring. assy group 10 / tank flap  Flap cut out and hole refilled with 2comonent mass for exactly fitting. With the idea that the tank should be fillable, the tank neck must also be designed accordingly. The first plastic nozzle with a glued cap was quickly removed and replaced with this brass tube with a copper cap. assy group 13 / rear window   This is the cut out for the rear window generation 7.  The sliding window stops in the central position by a stopper. A clip take care that the windows stay closed. that was largely the body, some details will follow of course  greetings, greetings,  Tobias Tobias

_____________________________________________________

Winter winds take flight, circling over my grave. A haunting voice amidst the trees, rising up across the sea.... (Katatonia) _____________________________________________________ |

|

Administrator

|

I keep saying WOW as I don’t know what else to say. That is so very much work, and so very well done. I’m in awe.

Gary, AKA "Gary fellow": Profile

Dad's: '81 F150 Ranger XLT 4x4: Down for restomod: Full-roller "stroked 351M" w/Trick Flow heads & intake, EEC-V SEFI/E4OD/3.50 gears w/Kevlar clutches

|

| Edit this page |