Search Forum

AC help needed please

1234

1234

|

Ok my 81 F100 that has factory AC (HVAC box & controls) (late compressor with vbelt used junk yard 1 years now)) has stopped working. The compressor has made noise from day 1 but has worked.

The evap is from the parts truck and was working till the roll over. System had psi on it till I pulled it apart. Hoses are also new other than from condenser to orifice valve, new dryer & valve when I got the system running a year ago. This last go around the compressor would kick on & off like low on charge and I seen because of dye in the system a leak at a fitting I did not touch or change the o-ring. The system has lost charge other times because of loose fittings but will not say from who  The last few times I just tighten the fittings and added more charge but each time did not blow as cold as the time before but figured I needed to pull a good vacuum before the next fix. Well I replaced the leaking o-ring, it was a black one to factory. Looked for any other leaks at all the fittings, none showed up. I pulled the orifice valve to see if it had any junk, it was clean but ........ When I pulled the valve out there was pressure on the evap side? I had the system open at the low side of the compressor so I would think the system would not of had any psi on it? A lot of oil & dye came out when it came out. Cleaned up the mess, checked the o-rings and put the system back together. I pulled vacuum for 30 mins to 29 hg. Let the system sit for 30 to 45 mins with pump off. It dropped to 28 hg and just figured system evened out. Changed the pump oil and pulled vacuum for little more than and hour down to 29 hg. Now this is where I think the issue starts? Start the motor, AC on MAX, fan high. Go to add 1 small can and I dont see anything going through the sight glass on the gauge set and the gauges dont really move till I shake the can. Can gets cooler as dose the hose. The PSI comes up enough to have the compressor start but stops when the psi drops, normal to me at this point (kind of) but think the can should have gone in and the PSI should have come up to run the compressor. I jump out the PSI switch, compressor runs all the time but the gauges dont really change much? I can see the line after the orifice valve gets ice on it but no cool air out the vents and the dryer is hot where I think it should be a little cool. I add a 2nd small can and the pSI comes up some but still not to the point of running the compressor all the time, kicks on & off. and making noise like it always has, kind of a clicking noise. Compressor not running I get L/H 100 / 100 Compressor running motor at high idle (1200 rpm) L/H 11 / 155 Compressor running motor at idle (800 rpm) L/H 20 / 155 Compressor will stay running at the 800 rpm idle but when you up the rpm it kicks on & off. I also bypassed the gauge set and used one of them short hoses with a gauge on the 2nd can. That gauge shows over PSI? I am thinking a bad compressor but with pressure on the system when I pulled the orifice valve I am not so sure? The system has factory service valve at the compressor and thinking I could close them, remove the old compressor, if it is bad. Install new compressor and open valves and be ok what you think? Is it the junk yard compressor and could I swap it the way I posted? I am almost to the point of giving it to a shop and have them fix it as I am tired of messing with it. Thanks for any help Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

first of all, what orifice tube is in it?

|

Blue and what the factory had in it with R12. Now I have had this system blowing cold with the blue valve when I first got the system working so I dont think its the blue orifice valve. I have also seen post between the blue or red and most go back to the blue as it blows colder. Again it worked before when the OAT has been in the upper 90's so I cant see it being the problem. Besides the loose fittings and needing a recharge each time it has blown warmer and warmer each time. I was thinking it needed a good vacuum pulled but now I wonder if the compressor has been going south this whole time? I know the noise is not normal but it worked so I did not look into it deeper. Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

Something I learned to do is use a bucket of warm water to put the can in to get it to empty as much as possible.

Not hot water, but warm, lukewarm or slightly more so. Are the high and low pressures different? If high and low are close in pressure, usually a sign of a bad compressor.

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

I know of the water trick but it was like it was not being pulled or sucked in to the system. I did set the cans on the intake / exh manifolds, 300 six so they are right there, that was warm and did not really help like it has in the past. 1200 RPM the low side was 11 / high 155 800 RPM low 20 / high 155 Compressor off both sides 100 / 100 What was strange is when I used the can hose with gauge on the low side of the system, the gauge said the PSI was to high / in the red? But the compressor would not stay running unless I jumped the switch. Other than the difference in PSI with the change in idle RPM only the low side changed not the high side. Its like it would pull a little but did not put out any psi noted at the 155 psi at the 2 different idle RPM's Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

Looks like it’s pumping. Odd that it’s not pulling it in.

I’ve had to leave the switch jumpered for 3 or more cans on bigger systems.

Dane

1986 F250HD SC XLT Lariat 4x4 460 C6-Sold 1992 Bronco XLT 4x4 351W E4OD 1998 GMC Sierra SLE K1500 350 4L60E Arizona |

|

Administrator

|

I have had the rubber seals where the hoses attach to the ports actually block the flow either due to swelling or squashing when attached. Darn near drove me crazy till I figured it out.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

But this system is not that big and other times I have charged it it took the cans. This time just seams strange the way it is charging? I do have 2 more small cans and some still left in the 2 that I used that I will have to heat to get the rest out. At first I thought it was the gauge set that I was using to add the first can through and why the 2nd can I used a short hose that hooks to the can and has a gauge with colors, no psi readings. I forget when it would go into the red, if when adding or resting? But what you say I wonder if the 134a to R12 fitting adapter could be the issue? If it was plugged / blocking like you say then the cans would not be pulled into the system like it should. Then again the gauge set was getting readings so I would think it is ok. Why do you think the high side stayed at 155 psi but the low side changed with RPM 11@1200 rpm / 20@800 rpm? Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

Administrator

|

Usually with that big a difference something is restricting the flow, but, if you are still getting gas through to the orifice tube it can give strange results. Does your system have one of the quick connect fittings in the liquid line from the condenser? I have seen these come apart internally and partially block the line.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

this is why I was asking. it is behaving as though it has a clogged orifice tube. the compressor creates differential, yet the orifice regulates it. I'm more concerned of this due to you saying earlier that there was contained pressure in the evaporator after evacuation and it was released upon removal of the orifice tube. sure sign of a stuck tube and I certainly hope you did not reinstall the same one. if you did then that would explain the system not drawing from the can.

|

No it has the high side by the compressor and the low side is up by the dryer. I did not "evacuate" like you maybe thinking  I had the system open to replace the leaking o-ring, it was the service valve to the compressor manifold that was leaking. If put that back together and moved on to the orifice valve. Being it was open I figured to pull the orifice valve to see if it had any junk in it because the evap was used and open for a few years but I did flush it out and used shop air to make sure when I first got the system working a year ago. Yea I was a little thrown off that there was PSI when I pull the valve and it pushed the oil out. But thinking maybe the compressor had something to do with still holding some pressure? I cant get back on it for a few days, work hours just kill me this way. But I will check a few things and see if I cant get some where with it. Thanks fore the help so far. Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

Administrator

|

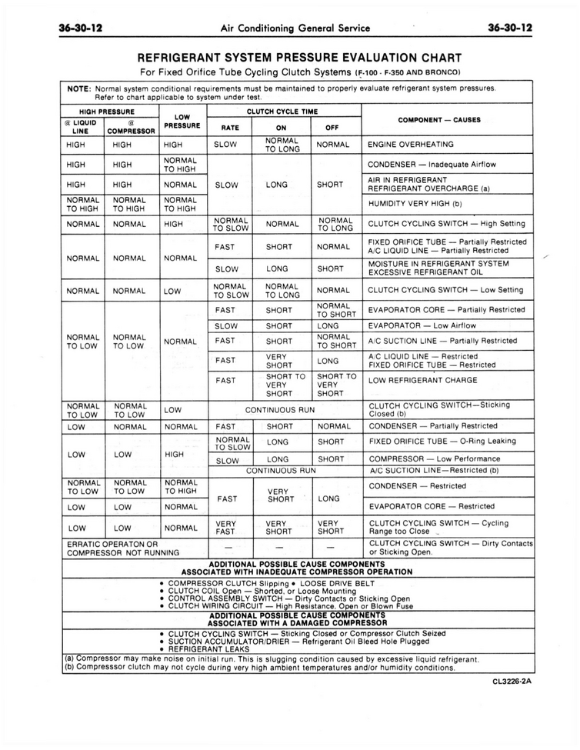

Like Mat, I was thinking an orifice tube issue or perhaps the evaporator core is plugged. Is your system 134? Here's good diagnostic chart for you:

John

"Blackie" - 1986 F150 4x4 - Mildly warmed over 351W HO - Original owner |

|

one of the dynamics of a fixed orifice refrigeration system whether it be one of our trucks or a window air conditioner or even the old deep freezer in the garage. is that the compressor creates pressure and by doing so, a positive flow of refrigerant. it must squeeze through the capillary portion of the orifice to get to the evaporator on the other side. this "damming up" of pressurized refrigerant allows the differential of the two pressures. suction side and discharge side. low and high. as soon as the compressor is turned off whether by the switch or turning off the truck, the system begins to equalize the two pressures. through the orifice! not through the compressor because the compressor uses a means of check valves. the only way for it to have contained pressure after being open for more than a few minutes is for the orifice to be clogged.

|

Yes it is 134a I will look over that chart better this weekend as it should be cooler and I will have a good head on me by then. Been getting up at 12 am for work working out side in 97*f heat and 100% humidity and not raining! I did give that some thought that the compressor "check valves" could hold the pressure back a little as I did not have the line off for vary long. What dose it take to pull the line, pull the old ring off and match for the size, oil it and stick it back together? Being the system was open for the o-ring I figured I would check the orifice valve if plugged. That was when I pulled it it has some pressure behind it but the valve was clean. I will look into what Bill said of the hose or adapter seals blocking so the change will not go in. After not being able to charge and get the system cooling I had to walk away before something bad happened  Thanks for the help guys Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

one of the best suggestions I can make is to start with a new tube. these are not expensive at all and not worth reusing if at all questionable. the orifice is a tiny capillary tube housed inside the blue plastic with the white cap. the sieve screen covers all it can but if the system was "open" for even one season worth of environmental changes, the "brass" orifice tube could easily corrode or even gunk up to the point of clogging itself and no debris even be visible on the screen.

|

I really dont think it is the valve. I say this because when I added the first can I used the gauge set hoses that has a 134 quick adapter and the whole can did not go in. I then placed the can on the intake / exh manifold to heat it up some but still did not push the full can. I then used a short hose that has a gauge & valve that screws onto the can and hooks to a 134 quick connection. When ever I tried to add the 2nd can by opening the valve the gauge went into the red. That is telling me when ever is in the can was not going into the system. Now my truck has R12 to 134a quick adapters so I can use the quick adapters from the gauge set. Going with something Bill said of having a hose seal blocking the "path way" I wonder if the R12 to 134a adapter seal is blocking the path way and the only time I can "push" a charge in is if the cans are new. I did not get out to test that but I am going to remove the adapter and see if I can hook the gauge set up to the low side like I did when I first charged the system a few years back. At that time I could not check the high side as the gauge set hose would not fit the R12 fitting. I also want to get a can or 2 more just in case. As for the valve if it will not take any more charge I will look into deeper why and swap out the valve. Oh yesterday when I did the weekly trash run I turned on the AC. When driving the compressor would turn on & off because the low side would go to low. But at idle the compressor would stay running and I could feel the air coming out the vents was a little cooler and I checked the line at the valve and it had frost on it. I hope if I can get the compressor to stay running and have the right charge it will cool again. Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

This post was updated on .

In reply to this post by Machspeed

Edit:

I was able to copy it to a word doc and print it out and can read it now Thanks John do you have a like to that chart? It is hard for me to read and would like to read it over better before I hit the truck again to fix this AC Dave ----

Dave G.

81 F100 flare side 300 six / AA OD / NP435 / 2.75 gear http://cars.grantskingdom1.com/index.php/1980-Ford-F100?page=1 81 F100 style side 300 six/SROD parts truck -RIP http://cars.grantskingdom1.com/index.php/1981-Ford-F100 |

|

in reference to the adapters. I know exactly what you mean. back about twenty years or so, a friend wanted to avoid this as a possibility, now he and I both have a lengthy air con history. that said we have multiple old gauge sets for different appliances and refrigerants. he took an old std. blue hose and cut it in half then took an old 134a blue hose and cut it. then spliced the required sections to make an adaptive hose for 134a guages to an old r12 car. we had the parts on the truck and no money spent. needless to say, we had a tool for years that "fit". no vehicle mounted adapters needed.

im not saying that anyone should do this as it may or may not breach certain safetys or regulations

|

|

In reply to this post by FuzzFace2

Here is my 0.02:

Typically when a compressor is heading South the needles on the guages will twitch like they're nervous. This is because the pump isn't sealing and is letting the pressure slip from one side to the other. I think maybe you're too heavy on the oil in the system and this is causing flow issues. I think I would take it apart and use some alcohol to flush the lines and condensor to get some.oil out. It doesn't seem like the.orifice is plugged or the low side would be trying to go to vacuum and the high side would be higher than Willie Nelson.

Whitey: 1996 F 250 XL CCLB 4X4 7.3 DI ZF5 (The Work Horse) Lots of power mods

Whitey Jr: AKA Jr 1982 F 150 CCLB 4X4 351W C6 (Jr Work Horse) respectable power, but not over the top The Bronco: 1987 Bronco XLT 351W C6 (needs work) Lots of off road mods and plenty of power mods The Dodge: 2006 Ram 2500 CCSB 4X4 5.9 HO Cummins (The reliable ride that cant keep an AC in itself) (5th AC go around almost complete) |

|

In reply to this post by FuzzFace2

I prefer the orange orifice tube. I can make them blow cold with any of them.

Another thing people don't like to consider because it's not that common is R152A is more of a direct replacement for R12 than R134A is. When swapping R12 to R152A use a multiplier of .55 for the charge. When saapping R134A to R152A use a multiier of .65 . So let's say the system calls for 10oz of R134A . 10 X .65 =6.5 oz is your R152A charge.

Whitey: 1996 F 250 XL CCLB 4X4 7.3 DI ZF5 (The Work Horse) Lots of power mods

Whitey Jr: AKA Jr 1982 F 150 CCLB 4X4 351W C6 (Jr Work Horse) respectable power, but not over the top The Bronco: 1987 Bronco XLT 351W C6 (needs work) Lots of off road mods and plenty of power mods The Dodge: 2006 Ram 2500 CCSB 4X4 5.9 HO Cummins (The reliable ride that cant keep an AC in itself) (5th AC go around almost complete) |

Bullnose Enthusiasts Forum

|

1 view|%1 views

| Edit this page |