Search Forum

Engine rebuild/mild modifications on my '86 302 EFI

12

12

|

I know everyone has their own opinion but consider what the end goal is expected to be. I prefer roller but im not avoiding building a non roller either . If originality has any value the i would consider that. Otherwise i would get another 5.0 later model roller and build it . Changing accessories to serpentine in the process

|

|

I'm not too concerned about originality but just wondering why you recommend getting a later roller block when I already have one. According to the PO it was rebuilt just 5000 miles ago. I intend to put a roller cam in it.

Steve

1986 F-150 XLT Lariat long bed, 2WD, 302 EFI, AOD, 3.55, dual tanks |

If it is a roller block and the lifter bores are tall enough you dont need a later block. If you wanted to get the best block out there how ever on the other hand you would want a F1SE roller block, from what I have read this iteration of the 302 design from 1991 was intended to be used on the 1991 Supercharged 302 Thunderbirds which they decided to not produce and the blocks became the standard. These blocks have thicker cylinder walls from what I have heard and 0.060" is well within acceptable over bore without overheating. I dont know how true that is, I just had my short block built by Creb Engineering and mine was bored 0.040" over with 0.040" over hyper flat top pistons with 8cc valve reliefs. If I ever had to rebuild this engine down the road I would have it checked before I decide if I want to sleeve the block to reuse it or just go 0.060" over. I am hopeful running synthetic oil will allow me to not have to bore the engine over when a rebuild comes along cause if I have to change blocks again, I am tempted to just drop a late model 7.3L Godzilla engine complete with automatic overdrive transmission and call it a day. Cause when I was looking for a roller block they were bit hard to locate locally and I had to go online to get one. Only other option would be the Boss 302 block that Ford Performance puts out but those block uses the oddball Cleveland mains which limits your choices to cast cranks which I dont understand why Ford Performance did something that stupid when their Boss 302 block when they know there is no performance aftermarket for the Cleveland blocks.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

In reply to this post by Sparky

Definitely the original engine then if you have a VIN stamped block. My '84 302 was stamped as well, and I've come across a couple others that were. It's seems to be pretty rare, and totally random, but somebody number matched them along the way (sometimes lol). Mine was stamped on the flat surface at the back of the block.   Congrats then on finally confirming the roller block. A roller block/cam isn't really necessary, but I'd say they're preferred so that you don't have be concerned with lifter and cam wear. I actually just sold a 1996 5.0 roller block engine. I could have kept the dogbones and hold down plate if I knew somebody needed them. Be careful drilling and tapping the two holes in the block. I seem to recall that they are directly on top of cam bearings? Also why the screws cannot be too long.

1994 F150 4x2 Flareside. 5.0 w/MAF, 4R70W, stock.

1984 F150 4X2 Flareside. Mild 302 w/ 5spd. Sold. 1980 F150 4X4 Flareside. 300i6 w/ 5spd. Sold in 2021. 1980 F100 4X2 Flareside. 351w/2bbl w/NP435. Sold in 1995 |

Yes, the bolt holes go through the cam journals and you have to have a short bolt or you can hit the cam bearing and lock the cam up. Ford Performance sells the roller cam retainer kit for like $40, comes new with OE spec Dog bones, OE spec spider, OE spec bolts and lock washers. Its what I used on my build as I am going from a flat tappet build to a full roller build. This is mine, 302H Ford Performance roller lifters (OE roller lifters with a ceramic check ball for 6,500 rpm stability) and Ford Performance roller lifter retainer kit.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

In reply to this post by Rusty_S85

Your build is much more high performance than mine will be. Just a mild cam, heads and exhaust. I think my stock block should be fine. It has not even been bored, just honed and new rings with the original pistons according to the PO. New crank and cam bearings also so the bottom end is pretty fresh.

Steve

1986 F-150 XLT Lariat long bed, 2WD, 302 EFI, AOD, 3.55, dual tanks |

|

In reply to this post by Rembrant

Mine is stamped in the same location as yours. As far as how deep to drill for the spider, Comp Cams has a kit and the instructions say not to drill any deeper than 3/8" into a non-roller block with no bosses so I assume you could go maybe 1/8" deeper if you have the bosses but going too deep would be a real problem.

Steve

1986 F-150 XLT Lariat long bed, 2WD, 302 EFI, AOD, 3.55, dual tanks |

|

In reply to this post by Rusty_S85

Wow, nice looking engine. Looks like you are doing it right. I want to clean mine up and paint it like you are doing and also clean up the engine bay. The Ford retainer kit looks like a good option. I will probably go with that, thanks.

Steve

1986 F-150 XLT Lariat long bed, 2WD, 302 EFI, AOD, 3.55, dual tanks |

|

In reply to this post by Sparky

One would think mine is high performance but in fact everything on my engine is the smallest aftermarket offering such as the AFR heads, they are 165cc heads and is the smallest they offer. The Crane TruckMaxx roller cam I have was the smallest truck/4x4/offroad cam they offered.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

High performance is a very relative term. Doing something that its designed to do well and efficiently is high performance. Building an engine is far more that assembling high performance parts. A lot of math is involved. All parts must work well with all other parts or you get an engine that does well here but not there or one that doesnt do anything any better. The hipo 289 was an engine that thought it was bigger than it really was because evrything worked together.

|

|

In reply to this post by Sparky

Well, I ordered a cam today. The general consensus seems to be that the Comp 35-512-8 is the best cam for my speed density truck and when I called Comp they agreed. It's fairly mild but should give a good improvement over my stock cam. They say 1200-5200rpm is the cam's range.

The next step is to decide on heads. I've got it narrowed down to the AFR 165cc, Trick Flow 170cc, Brodix ST 5.0 R 171cc and the Edelbrock E-Street 170cc.The prices range from about $2000 for the AFRs to about $1200 for the E-streets with the other two in the middle. My questions are mostly concerning intake valve size and combustion chamber size. Some offer an intake valve of either 2.02" or 1.90". For low end torque should I be using the smaller valve? For combustion chamber, is smaller better? What is too small? The sizes of combustion chambers offered for the above heads range from 61cc to 55cc. I'm not sure how to figure the new compression ratio since I can't find any good info on the chamber size of my current E5TE heads. I believe the stock compression ratio for my truck is 9.0 to 1. Any help on the above questions would be appreciated. If you have any comments on the heads I would like to hear them. I am looking for the most bang for my buck, not necessarily the absolute best performance.

Steve

1986 F-150 XLT Lariat long bed, 2WD, 302 EFI, AOD, 3.55, dual tanks |

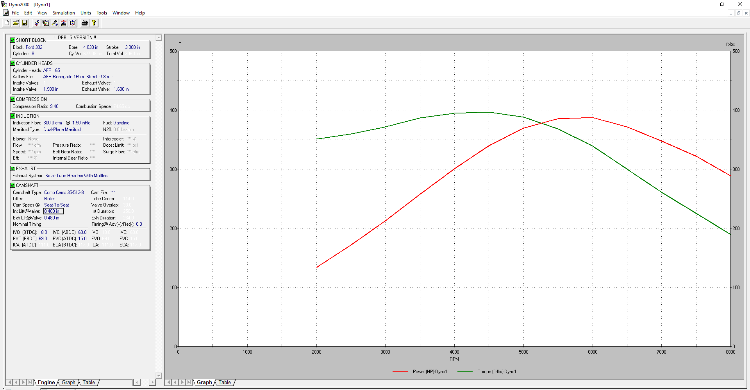

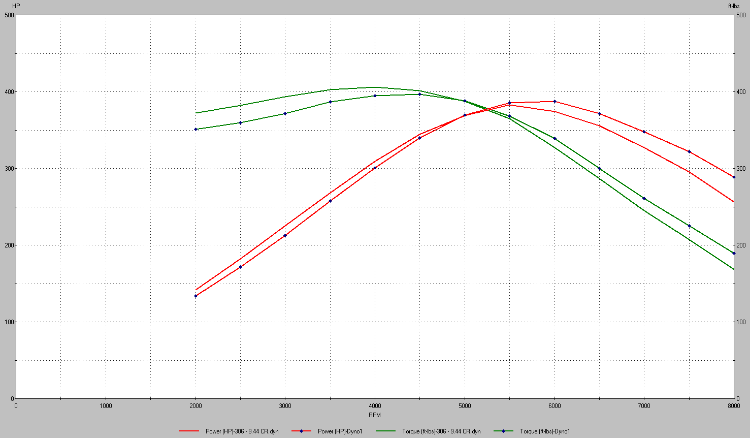

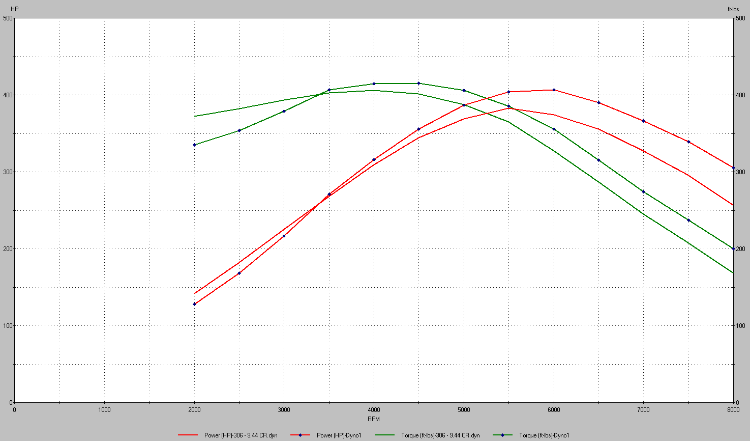

Be careful with the E-street heads, unless they changed when I looked at them years ago they are not for hydraulic roller cam engines. I think its the heads arent cut for heavier duty valve springs to keep the roller lifter under control. If you are wanting low end torque for a 302 opt for the 1.90" valve, it also is more forgiving with OE style pistons as the 1.90" valves will fit the OE piston valve notches while the 2.02" valves will not and will require fly cutting the piston or going with a dished piston. The 1.90" valve will also be better for street use on a 302. On the E5TE heads as far as chamber size and all that, the following is the site I use for OE Ford cylinder head specs. https://www.carbdford.com/tech/flowdata.htm They dont have specs for your specific heads but looking online it appears your E5TE heads are 62 - 65 cc chambers. As far as figuring out compression you have to know what your deck clearance will be and go from there. If you go a similar route as I did this is what you would be looking at flat top hyper pistons with 8cc valve reliefs 4.030" bore 4.100" x 0.039" head gasket 0 deck 63cc heads 8.89:1 compression. With AFR cylinder heads the 165 Renegade with 58cc heads you would be looking at 9.42:1 compression. Now if you have like me 0.040" quench and not zero deck which is right in the middle of ideal quench of 0.038" - 0.042" with 63cc heads you are looking at 8.87:1 compression With AFR cylinder heads you would be looking at 9.40:1 compression. My 302 is bored 0.040" over so my bore is 4.040" with 4.100" x 0.039" head gasket and 0.001" deck clearance for 0.040" quench with Renegade 165 heads with 58cc chambers which gives me 9.44:1 which is close enough for my 9.50:1 goal which is what the 5.0 Explorer engines were rated at with GT40 heads was 9.5:1. Thing you have to look at is what compression your cam wants and go for that cause a cam with more over lap will bleed compression off and youll need more static compression. This is what DD2000 came up with if you run the AFR 165 heads with 9.40:1 compression with a 600cfm 4V carb, small tube headers with mufflers and the 35-512-8 roller cam. Peak hp 388 @ 6,000 Peak trq 397 @ 4,500 With stock manifolds you would be looking at the following Peak hp 324 @ 5,500 Peak trq 355 @ 3,500-4,000 To compare your cam to mine 35-512-8 RPM operating range 1,200 - 5,200 114* LSA 110* ICL 206*/212* @ 0.050" lift 0.480"/0.480" valve lift HR-216-325-2S-12 RPM operating range 1,400 - 5,400 RPM cruise 2,400 - 3,000 valve float 6000 112* LSA 107* ICL 117* ECL 216*/224* @ 0.050" lift 0.520"/0.542" valve lift Thats where mine makes a little bit more power than your cam, the extra lift makes use of the most flow from the AFR heads. Your 0.480" lift would still result in the AFR heads out flowing your OE castings. This first one is your build with the 35-512-8 cam and AFR Renegade 165 cylinder heads  This second one is yours the diamond marked lines vs my build to show a comparison of the torque curve.  Remember that is with a 600cfm 4V carb. I dont know what the flow rate of the factory throttle body, I know there were two different sizes a 58mm and a 60mm and I know people argue between 800cfm and 1,000cfm. This is a comparison chart with sequential EFI with 1,000 cfm but it will be a big guess still and goes to show the output is only as accurate as your input information.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

Thanks for all the good info. I don't have time for a proper reply tonight but I will try to digest all this and figure out which direction to go. The PO told me that when he rebuilt the engine he just honed the cylinders and put new rings on the original pistons (which are flat top with valve reliefs) and I assume that he did not have the deck machined but I don't know that for sure, so I believe that all dimensions are stock.

Steve

1986 F-150 XLT Lariat long bed, 2WD, 302 EFI, AOD, 3.55, dual tanks |

|

My low budget 302 build is this. F1SE roller block - bored .020, flat top pistons with valve reliefs, GT-40 3 bar heads with comp cams springs, E303 cam, OE roller lifters, ProForm roller tipped rockers, Edelbrock Performer 289 intake, Holley 600 cfm carb, and a recurved DS-II distributor.

I shopped wrecking yards, swap meets, craigslist, friends, etc. All in, I'm under $1500. Hoping to be in the 300 hp range, anyone think I'll make it??

Ford Parts Monkey since 1985

1981 F100 Flareside - Black, 302-4V Roller/AOD 1986 F150 Flareside - Medium Fire Red 302/AOD 1989 F150 Standard Cab 4x4 - Dk Shadow Blue 302/AOD 1993 F350 4x4 Crew Cab - 7.3 IDI/ZF-5 I think it's a sickness... |

|

In reply to this post by Rusty_S85

Regarding the E Street heads, their description definitely says "for flat tappet cams only" but the Comp Cams tech I talked to said they can handle my roller cam no problem. Kind of confusing. I think the springs they use are kind of wimpy and can only handle a mild roller cam like mine. Still, I'm not sure whether to trust them. If something goes bad down the road they will just fall back on the "flat tappet only" statement. I checked my deck clearance today using the straight edge and feeler gauge method. I checked pistons #1 and #4. #1 was at .028" and #4 was about .030". I'm pretty confident I'm in the ballpark with these numbers. That seems pretty far in the hole to me. I guess I would have to have the block milled about .028" or so to reach an optimal quench. How important is quench? I also need to call Comp Cams again to see what they think about the CR for my cam. Based on these numbers I'm coming up with a CR of 8.15:1 (4.000 bore, .047 gasket, 8cc valve reliefs, .028 clearance, 63cc heads) for my all-stock truck. I've seen smaller numbers used for valve reliefs, more like 3cc's. I saw an old post on FTE where Rembrandt from this forum was discussing CR's and he was told that his slightly dished pistons with valve reliefs were somewhere around 3-5cc's. Maybe he can weigh in. At 3cc's my CR would be 8.6:1. I would love to make 388 HP but I am expecting more like 300.

Steve

1986 F-150 XLT Lariat long bed, 2WD, 302 EFI, AOD, 3.55, dual tanks |

|

In reply to this post by myrl883

I'm a newb at this stuff but I think you could make 300HP with that combination. I'll let others weigh in on whether that is the right cam for a truck. In any event, $1500 is a great price for a nice build.

Steve

1986 F-150 XLT Lariat long bed, 2WD, 302 EFI, AOD, 3.55, dual tanks |

|

In reply to this post by Sparky

Yep 0.028" - 0.030" is quite a bit with a 0.039" head gasket youll be right at 0.060" quench which is excessive. Case in point I found true tdc with a piston stop when I did my cam degreeing to verify installation and I measured using a dial caliper and I found mine on the center line of the piston (the piston can rock side to side slightly) was right at 0.0010" to 0.0015" so I just went with 0.001" which on a 0.039" thick headgasket comes out to 0.040" quench. Anything over 0.050" quench will have a high risk of causing detonation as ideal is 0.038" to 0.042" and I shot for right in the middle at 0.040" On the valve reliefs it depends on what pistons you use, mine are 4 valve relief hyper pistons which are rated at 8cc for the valve reliefs. If you go with a forged piston with just 2 valve reliefs per piston you would have less cc and will bump up the compression. I just wanted hypers as they can be fitted tighter to the cylinder which helps the engine to run quieter due to how stable hypers are and their very minimal expansion when heating up. Power wise my goal was 300hp. DD2000 states closer to 390hp but I realistically think with my shorty headers into a OE style 2 1/2" Y pipe with a straight back 2 1/2" single exhaust into a 2 1/2" Magnaflow XL3 chamber round muffler into a 2 1/2" tail pipe I think I would be more or less around 325hp to 350 hp at the flywheel. But my goal was always 300 hp that is over double what my smog 302 makes which is just over 100 hp. I know its not much over 100 hp cause my '78 351W is rated at 145 hp so the 302 would be in the neighborhood of 110 - 120 hp I figure. That coupled with a custom built C6 transmission with a E40D planetary gear set, r type servo and piston with kevlar bands, RV shift kit a hughs XTM tow converter and a black stripe vacuum modulator matched up to a 3.25:1 detroit tru trac 9" carrier I should see a big boost to performance with my 31x10.50-15 tires over the worn out stock C6 trans I have with a stock smog 302.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

|

In reply to this post by Rusty_S85

Rusty, just wondering how much you had to take off your deck to get to .001" deck clearance. A machine shop I talked to said they wouldn't recommend taking more than .010" off or it would affect the fit of my intake. My pistons are currently about .030" down before any machining. Did you have your intake machined also? I would like to get closer to your numbers as far as quench and CR go. What gas are you planning to use?

Steve

1986 F-150 XLT Lariat long bed, 2WD, 302 EFI, AOD, 3.55, dual tanks |

Its hard to say. You have to know what pistons you are using as well as pistons can have difference compression heigths. Mine the block was prepped and assembled for me by Kreb Engineering and was shipped to me I couldnt find a local shop I trust let alone one that could get me a roller 302 block built in a short period of time. As of right now the three local engine shops to me are telling people its right now a 2 1/2 year turn around due to the volume of rebuilds that they are getting.

"Old Blue" - '56 Fairlane Town Sedan - 292-4V, Ford-O-Matic transmission, 3.22:1

'63 Belair 2dr sdn - 283-4V, Powerglide transmission, 4.56:1 '78 Cougar XR7 - 351-2V, FMX transmission, 2.75:1 9inch "Bruno" - '82 F150 Flareside - 302-2V, C6 transmission, 2.75:1 9inch, 31x10.50-15 BFG KO2 |

Bullnose Enthusiasts Forum

|

1 view|%1 views

| Edit this page |