Search Forum

Carburetor Setup Question

|

Hi everyone,

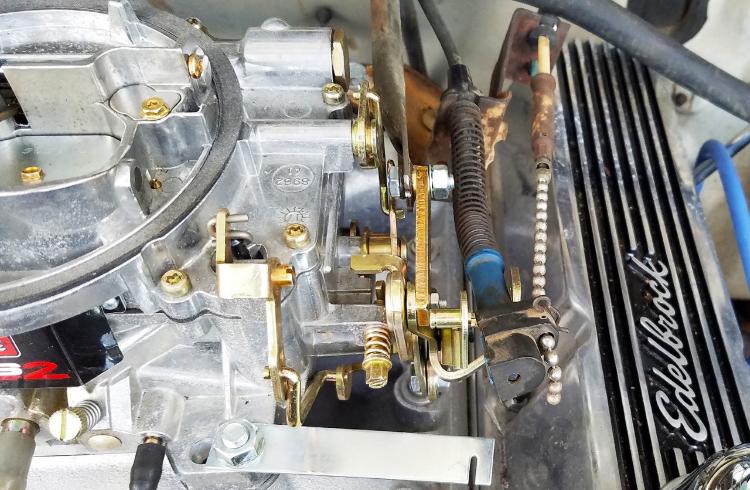

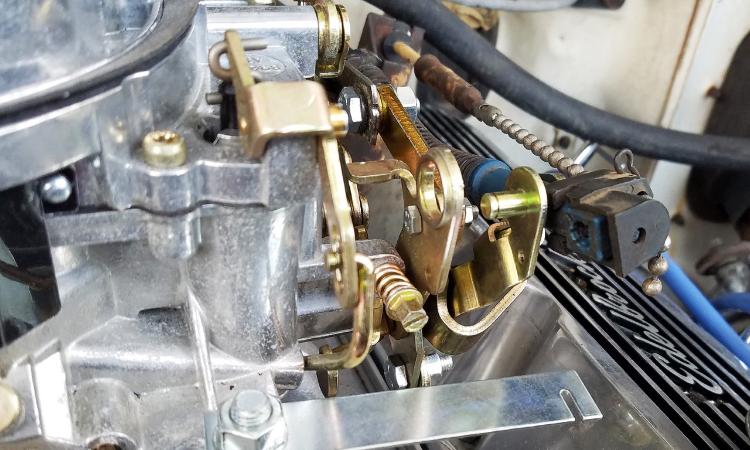

I've been trying to add a throttle linkage setup to an Edelbrock AVS series carburetor that I have installed on my 351W with a C6. Following will be a bunch of images that I took to try and show you where I'm at. So far, I've added the transmission shift cable plate and also the linkage adapter for the 351W, which I would appreciate anyone having a look at to see if it's installed correctly, I believe so but having more experienced eyes take a look would be much appreciated. That being said, I'm still having an issue with the actual throttle connecting to the linkage via a ball end connector. Do I need a completely different "connector" as opposed to the blue/black one that is there from Ford? At the moment, I have the throttle cable end connector just sitting in the vicinity of where I believe it should go. It seems that there are two cables in this setup - one that runs through the firewall, and another that runs into some type of actuator near the brake booster (from memory). Also, the return spring that was included in the Edelbrock throttle kit was too large for the setup (you'll note that I installed the spring plate on the front, driver's side stud on the intake manifold carburetor plate - as per the manufacturers instructions. The assembly kind of pivots in a circle motion, and in these images, it is NOT in the upward location which is where I believe it should be - but even when it is in that upright position, the Edelbrock spring is way too big (the Ford spring is huge). What am I missing here?

1985 Ford F150, 2WD.

351 H.O Windsor, aluminum heads Cam: Lift = .496''/.520'' Duration @ .050: 224°/234° C6 Transmission 6" Rough Country Lift 33x12.5x15 BF Goodrich All-Terrains 15x10" Pro Comp Rims |

|

Administrator

|

First item, the outer lever, if it is locked to the inner with a screw (Holley does this on their Ford linkage kits) will need to be loose so it can move back to allow the blue connector to be snapped over the ball. The ball should be installed where you have the downshift rod extension at present, remove that and put the ball there. Downshift rod attaches to the round pin on the outer lever. Once this is done, the outer lever is the downshift portion, it only moves about 1/2-3/4" back at full throttle. If the truck had the HO 351, then the downshift rod should be long enough to reach without the extension. If not then, prop the choke in the open position and with the downshift lever loose, open the throttle fully. If the downshift rod end, when pushed down and back (it moves down at the transmission end) will line up with the downshift lever pin, then connect it, if it is too far back, then the extension is needed.

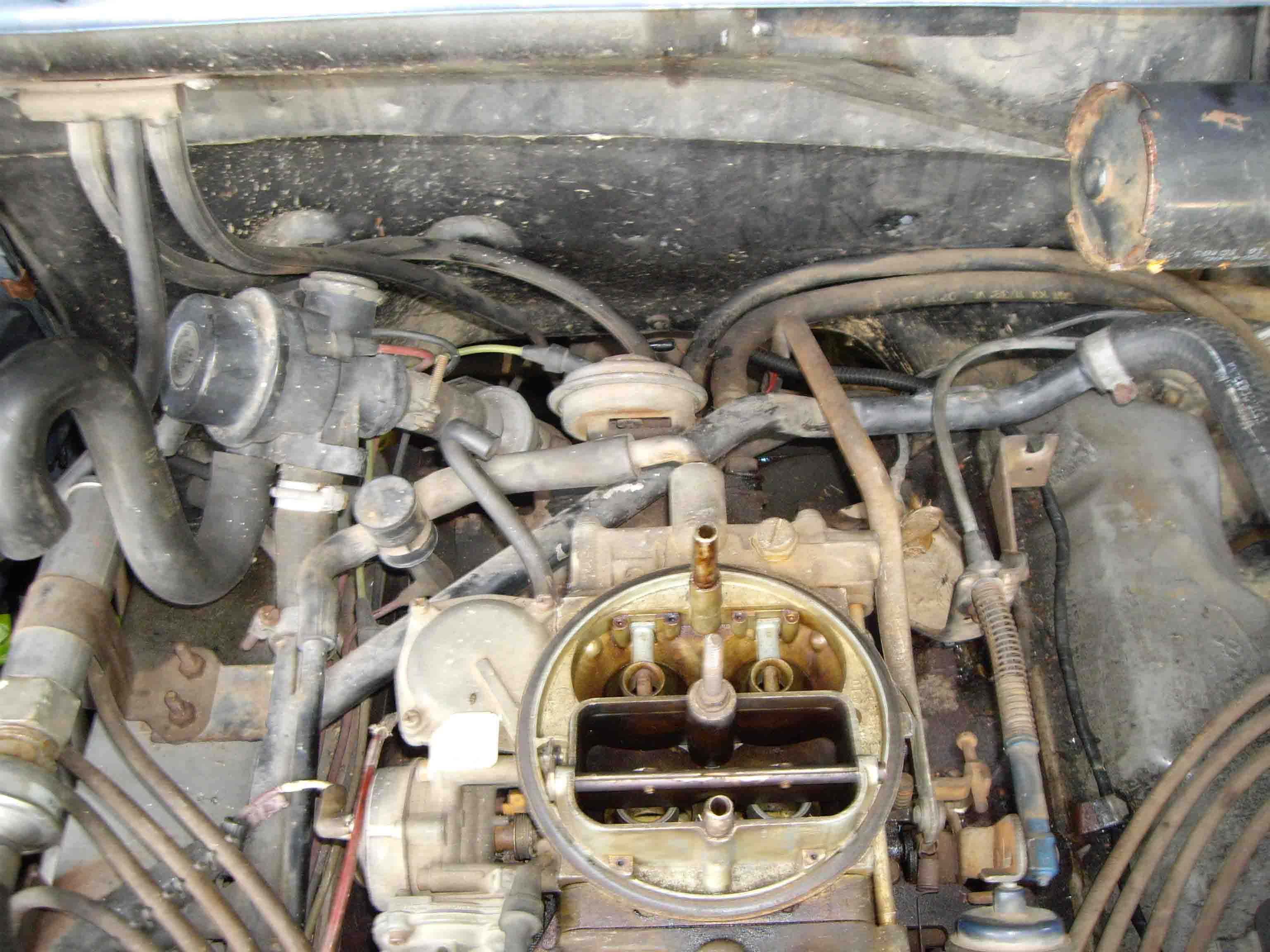

Here is a Holley 4180 setup, the throttle cable and downshift rod locations are reversed from a Carter.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

|

Thanks 85lebaront2 and thanks for the pic. The Holley setup looks a lot more logical to me.

I wish you could see the larger images I posted - as when they are the full size of the file, everything is a lot easier to see and I probably should have moved the throttle cable connector out of the way before I took the pics. The issue that started all of this was - on my truck, the part where the ball end is supposed to be on the carburetor did not have a thread to accept a ball-end connector (the type that I purchased from Jegs was a "pack" that had a bunch of different sizes and lengths). When I called Edelbrock for a solution, they said that I needed the linkage kit and the shift plate, so I'm still stuck there as there is no way for the existing throttle ball connector to hook up. I'm trying to go off memory, but I recall there being an issue with the throttle cable if I try to position the blue/black connector further back... Regarding the downshift lever, that makes sense but I will need to check on the amount of room I have to play with. However, what keeps it in place on the pin? The kit did not come with a clip or retainer. Also - won't the throttle cable rub against the trans shift rod (even if the throttle is positioned further back)? Thanks again.

1985 Ford F150, 2WD.

351 H.O Windsor, aluminum heads Cam: Lift = .496''/.520'' Duration @ .050: 224°/234° C6 Transmission 6" Rough Country Lift 33x12.5x15 BF Goodrich All-Terrains 15x10" Pro Comp Rims |

|

Administrator

|

The problem with using a Carter AFB or AVS in place of a Holley is twofold, (a) the Carters are wider than a Holley, but shorter front to back so the cable ends up at an angle, (b) the relative position of the throttle and downshift levers are reversed so the downshift rod sits outside the throttle cable rather than inside. Did the Edelbrock kit come with a different mount for the cable? This would move it outboard so it pulls straight and might allow the downshift rod to be positioned so it does not interfere with the cable. The groove on the "stud" of the downshift lever is for an "E" ring clip, the hole in the front is for the extra spring, from there to the flat piece on the driver's side front carburetor mounting screw.

The reason the Holley looks more logical, it is what Ford put on their V8s except for a few. I had one, a Lincoln 430, they used what was also described as a "Daytona" AFB, with a Holley bolt pattern and larger air filter circle. Even the Autolite/Motorcraft 4100/4300 are still based on the Holley dimensions as far as width and downshift rod design. For driving the truck, at worst case leave the downshift rod off until you get the rest of the linkage working right. Where in Fla are you, I have a friend (fellow Ford nut) in Gulfport MS who might be able to help you if you can get to him. He is a former Seabee and a pretty decent mechanic.

Bill AKA "LOBO" Profile

"Getting old is inevitable, growing up is optional" Darth Vader 1986 F350 460 converted to MAF/SEFI, E4OD 12X3 1/2 rear brakes, traction loc 3:55 gear, 160 amp 3G alternator Wife's 2011 Flex Limited Daily Driver 2009 Flex Limited with factory tow package Project car 1986 Chrysler LeBaron convertible 2.2L Turbo II, modified A413 |

Bullnose Enthusiasts Forum

|

1 view|%1 views

| Edit this page |